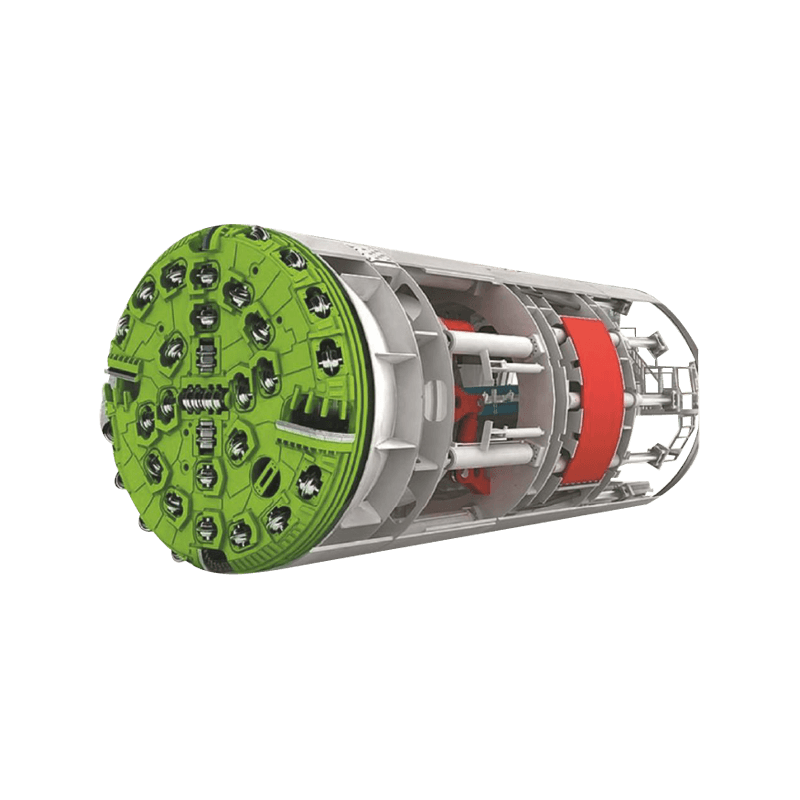

As China Pipe Jacking Machine Manufacturers and Pipe Jacking Machine comapny, Yangzhou Dilong Machinery Co., Ltd. is a professional production enterprise that integrates the design, manufacturing, and service of various non-excavation equipment. It mainly produces mud water balance pipe jacking machines, soil pressure balance pipe jacking machines, rock pipe jacking machines, rectangular pipe jacking machines, relay rooms, and various pipe jacking supporting equipment between 1000-4500mm.

The company is located in Jiangdu District, Yangzhou City, adjacent to Suzhong Airport, Ningqi Railway, and Beijing Shanghai Expressway, with convenient transportation and smooth logistics. The company covers an area of 80 acres, has 100 employees, an annual output value of 100 million yuan, complete large-scale processing equipment, and strong strength.

Since its establishment, the company has aimed at the goal of "quality and brand, crossing the globe, and building a non-excavation production base", widely absorbing advanced technologies from home and abroad, constantly keeping pace with the times, innovating and improving. We offer Custom Pipe Jacking Machine. Its professional equipment has reached a high level in the industry and has won the recognition and trust of users with product quality, on-time delivery, and thoughtful service. Its products are sold to many countries in Southeast Asia, the Middle East, and Africa, and enjoy a good reputation in the industry.

Sincerely welcome friends from all walks of life at home and abroad to visit negotiate, and seek common development.

Welcome to Yangzhou Dilong Machinery Co., Ltd.

Follow us:

-

Slurry Balance Pipe Jacking Machine

-

Earth Pressure Balance Pipe Jacking Machine

-

Rock Pipe Jacking Machine

-

Earth Pressure Balance Rectangular Pipe Jacking Machine

-

Auger Boring Machine

-

Slurry Balance Shield Machine

-

Earth Pressure Balance Shield Machine

-

Hard Rock Tunnel Boring Machine-Single Shield TBM

-

Hard Rock Tunnel Boring Machine-Double Shield TBM

-

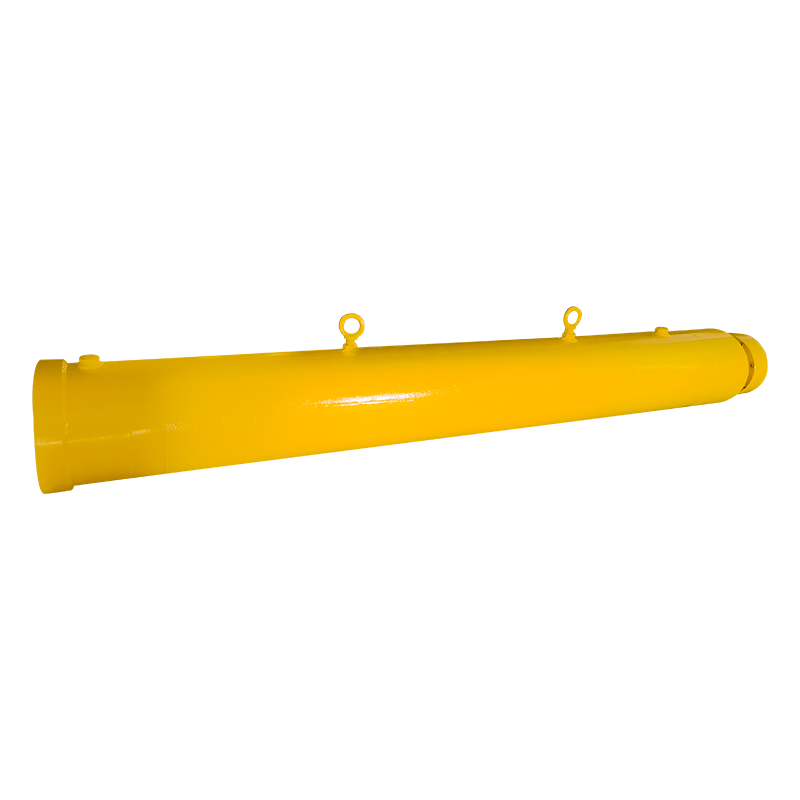

Oil Cylinder

English

English  русский

русский  عربى

عربى