A pipe jacking machine is specialized construction equipment used to install underground pipelines without digging open trenches on the surface. It works by pushing pipes horizontally through soil using powerful hydraulic jacks. This method is widely used for sewage lines, water supply pipes, drainage systems, and utility tunnels, especially in urban areas where roads, buildings, or railways cannot be disturbed.

Compared with traditional open-cut excavation, pipe jacking construction reduces surface damage, shortens construction time, and lowers restoration costs. Modern pipe jacking machines are often combined with guidance systems and cutting heads to handle different soil conditions accurately.

How a Pipe Jacking Machine Works in Real Projects

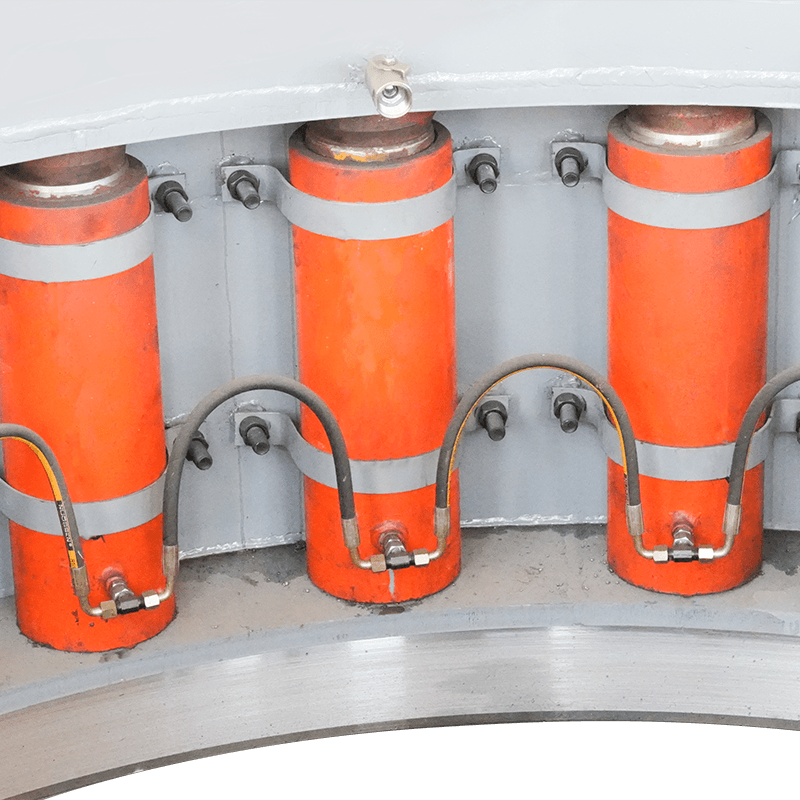

In actual construction, a pipe jacking machine operates from a launch shaft. Hydraulic cylinders apply thrust to push prefabricated pipes forward while the machine excavates soil at the front. As each pipe section advances, a new pipe is added from the rear, forming a continuous underground pipeline.

Main Working Steps

- Build launch and reception shafts at both ends of the pipeline

- Position the pipe jacking machine and align it using a guidance system

- Excavate soil at the front while hydraulic jacks push the pipe forward

- Add pipe sections one by one until reaching the reception shaft

Key Components of a Pipe Jacking Machine

Understanding the core components helps operators and project managers choose the right pipe jacking equipment. Each part plays a critical role in safety, accuracy, and efficiency.

- Cutting head: Breaks and excavates soil, clay, sand, or soft rock

- Hydraulic jacking system: Provides thrust force to push pipes forward

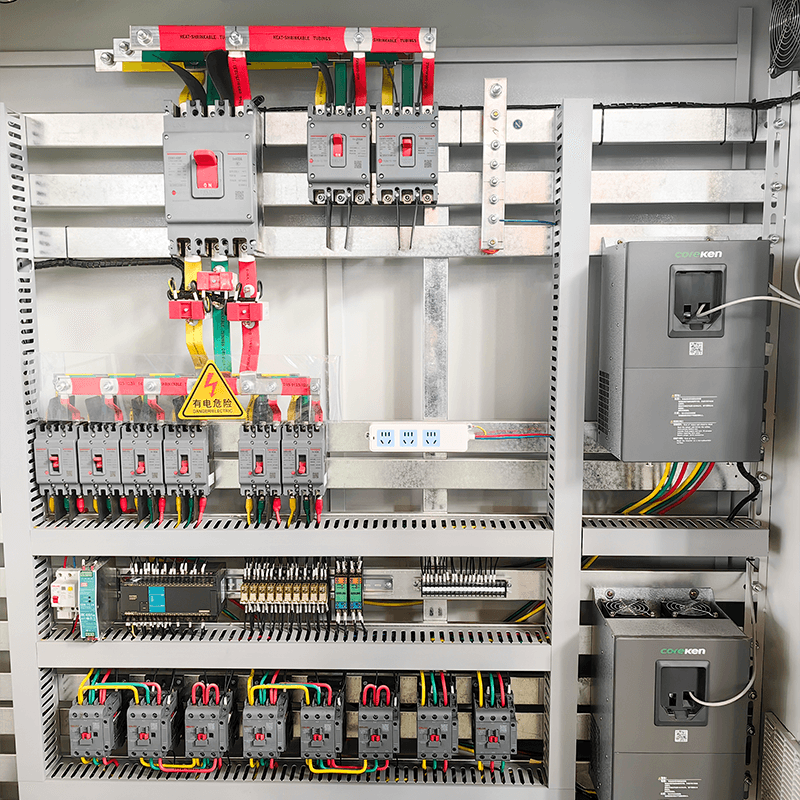

- Guidance system: Ensures accurate alignment and direction control

- Slurry or screw conveyor system: Removes excavated soil efficiently

Types of Pipe Jacking Machines and Their Applications

Different ground conditions require different pipe jacking machine designs. Choosing the correct type can significantly reduce risks and improve construction quality.

| Machine Type | Suitable Soil Conditions | Common Applications |

| Manual Pipe Jacking Machine | Soft soil, short distances | Small drainage or utility pipes |

| Slurry Pipe Jacking Machine | Sand, gravel, high groundwater | Municipal sewage and water pipelines |

| Earth Pressure Balance Machine | Clay and mixed ground | Urban underground projects |

Advantages of Using a Pipe Jacking Machine

Pipe jacking technology offers practical benefits that make it a preferred solution for underground construction in crowded or sensitive areas.

- Minimal surface disruption to roads, buildings, and landscapes

- Lower environmental impact and reduced noise

- High installation accuracy for long-distance pipelines

- Reduced overall project restoration and traffic costs

What to Consider When Choosing a Pipe Jacking Machine

Selecting the right pipe jacking machine is not just about size or price. Project conditions and technical requirements must be carefully evaluated.

Key Selection Factors

- Pipe diameter and jacking length requirements

- Soil type, groundwater level, and geological risks

- Available space for shafts and equipment setup

- Maintenance support and spare parts availability

Common Problems in Pipe Jacking and Practical Solutions

Even with advanced pipe jacking machines, challenges can occur during construction. Knowing common issues helps teams respond quickly and avoid costly delays.

- Pipe deviation: Correct using real-time guidance and steering adjustments

- High jacking force: Reduce friction with lubrication systems

- Soil collapse: Stabilize face pressure and adjust excavation speed

Future Trends in Pipe Jacking Machine Technology

Pipe jacking machines are evolving toward smarter, safer, and more efficient designs. Automation, digital monitoring, and improved cutting tools are helping contractors handle longer drives and more complex ground conditions with confidence.

As cities continue to grow and underground space becomes more valuable, pipe jacking construction will remain a key solution for modern infrastructure development.

English

English  русский

русский  عربى

عربى