A TBM machine, short for Tunnel Boring Machine, is heavy-duty equipment designed to excavate tunnels through soil and rock with high precision. It is widely used in subway systems, railway tunnels, highway tunnels, and water conveyance projects. Compared with traditional drilling and blasting, a TBM machine offers better safety, smoother tunnel walls, and minimal disturbance to surrounding ground.

Modern TBM machines integrate mechanical cutting, structural support, and spoil removal into one continuous operation, making them ideal for long-distance underground construction.

How a TBM Machine Works on Site

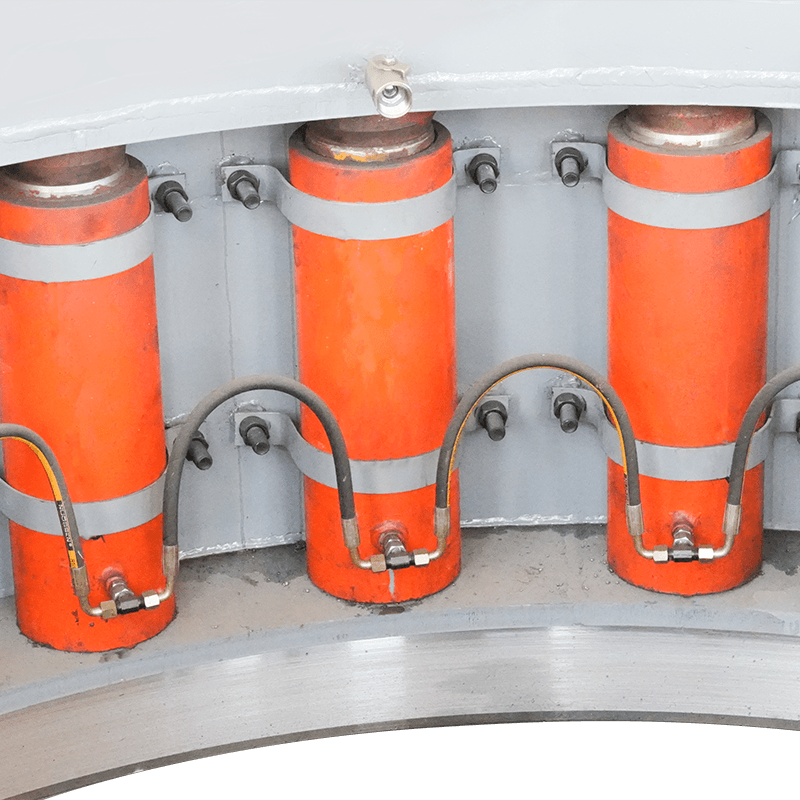

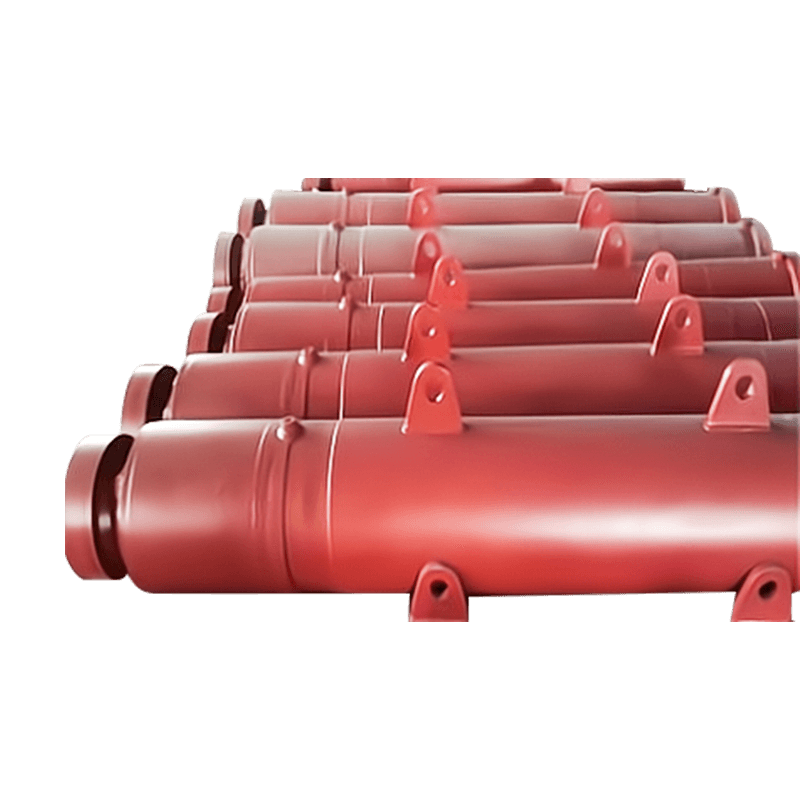

A TBM machine advances forward by rotating a cutterhead equipped with cutting tools. As the cutterhead breaks soil or rock, hydraulic thrust cylinders push the machine ahead. Excavated material is transported out of the tunnel through conveyor belts or slurry systems.

Basic Working Process

- Cutterhead rotates and excavates ground

- Hydraulic cylinders push the TBM forward

- Excavated material is removed continuously

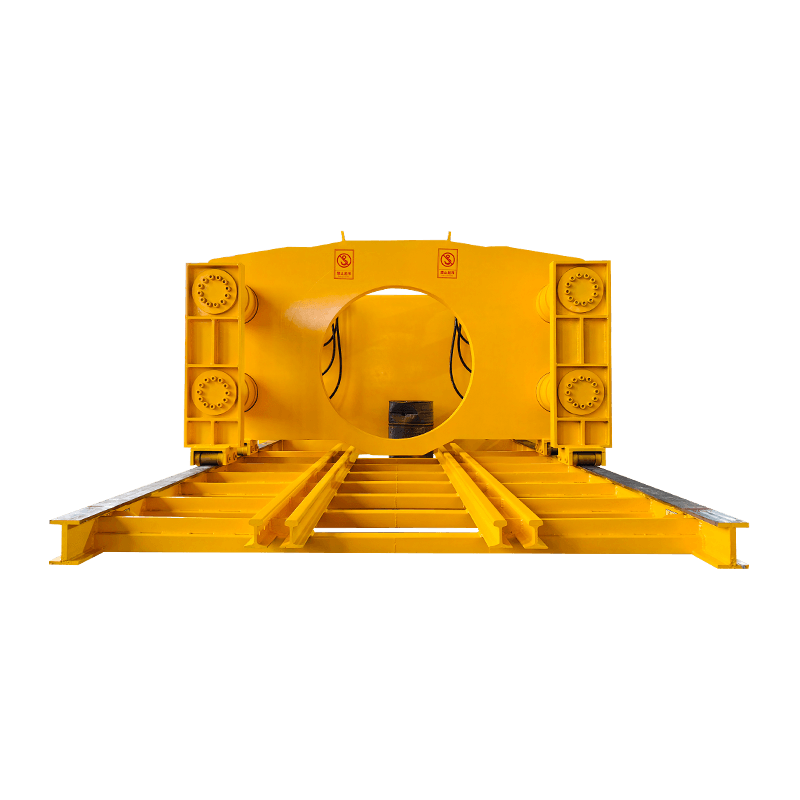

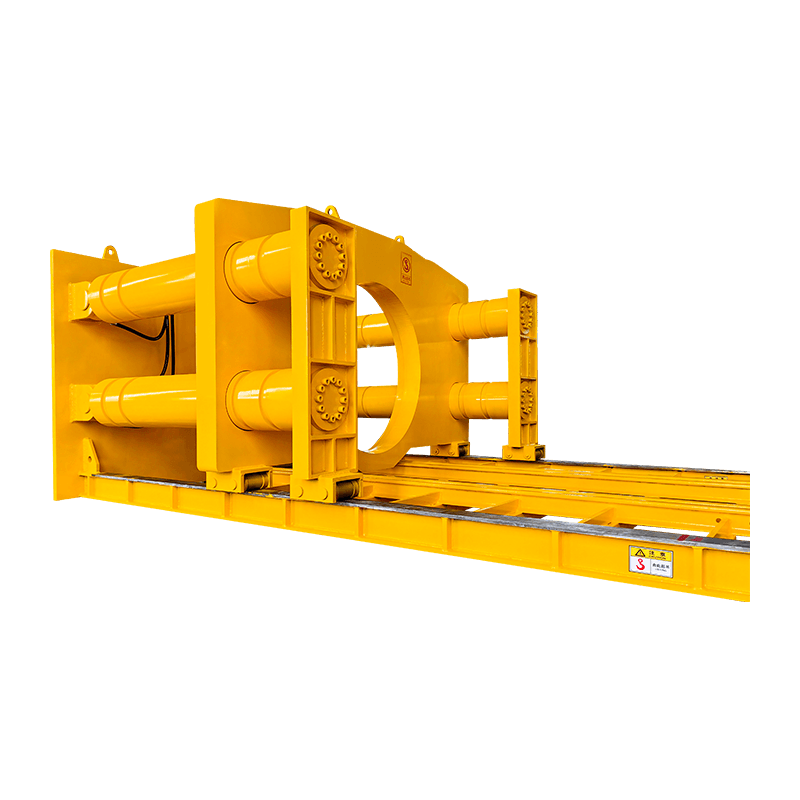

- Tunnel lining segments are installed behind the machine

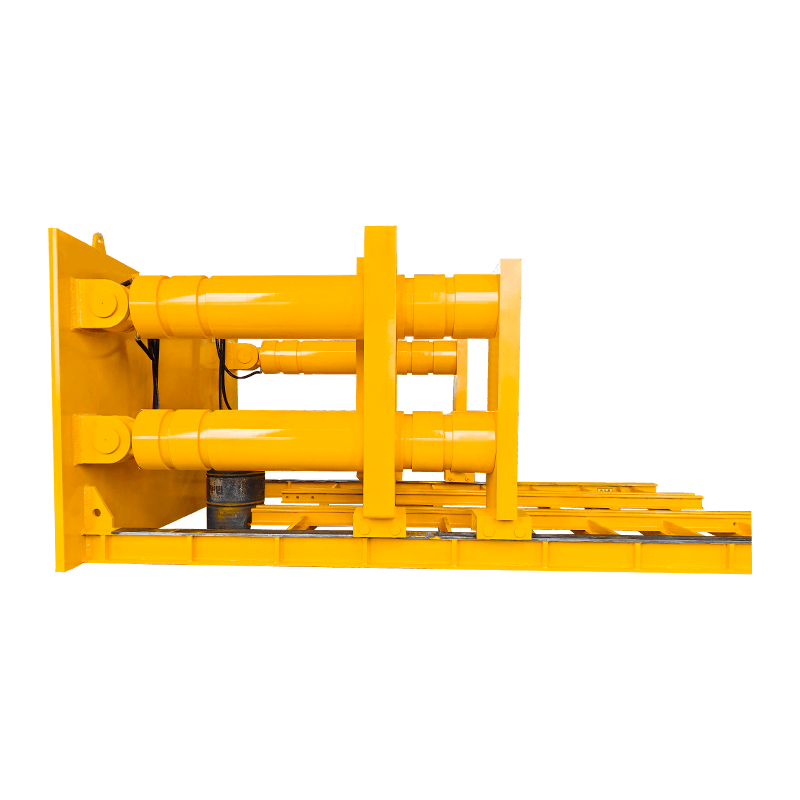

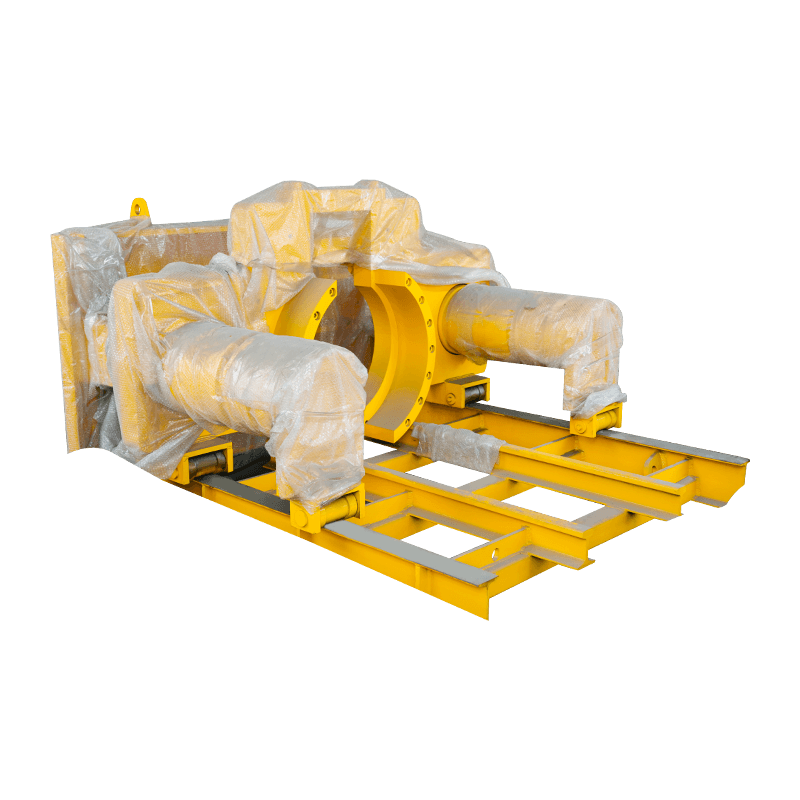

Main Components of a TBM Machine

Each part of a TBM machine plays a key role in maintaining excavation accuracy and structural safety during tunneling operations.

- Cutterhead with disc cutters or drag bits

- Thrust system for forward movement

- Segment erector for tunnel lining installation

- Guidance and control system for alignment

Advantages of Using a TBM Machine

TBM machines are preferred in large infrastructure projects because they offer stable excavation and predictable performance.

- High tunneling accuracy and smooth tunnel walls

- Reduced ground settlement and surface impact

- Improved safety for workers

- Efficient excavation for long tunnels

Typical Applications of TBM Machines

TBM machines are commonly used in projects where precision and environmental protection are critical.

- Metro and subway tunnel construction

- Railway and highway tunnels

- Water transfer and drainage tunnels

English

English  русский

русский  عربى

عربى