When it comes to constructing underground pipelines, especially beneath roads, railways, or buildings, avoiding surface disruption is a major challenge. This is where Pipe Jacking Machines play a crucial role. Also known as trenchless tunneling equipment, these machines allow pipes to be installed underground without digging long trenches on the surface. In this article, we will explore what a pipe jacking machine is, how it works, its key components, applications, and advantages in modern infrastructure projects.

1. What is a Pipe Jacking Machine?

A Pipe Jacking Machine is a mechanical device used for the trenchless installation of underground pipelines. It pushes or “jacks” prefabricated pipes through the ground from a launch shaft to a reception shaft, forming a continuous underground tunnel. This method minimizes surface disruption and is ideal for dense urban areas or under existing structures.

The process is part of what’s commonly referred to as microtunneling when the operation is remotely controlled, typically for smaller diameter pipes.

2. How Does a Pipe Jacking Machine Work?

The basic working principle involves hydraulic jacks that push pipes behind a cutting head or shield. Here’s a step-by-step breakdown:

-

Shaft Construction: Two vertical shafts are built—one to launch the machine and another to receive it after the pipe is laid.

-

Machine Launching: The pipe jacking machine, often with a cutting head or tunnel boring attachment, is placed at the launch shaft.

-

Soil Excavation: The cutting head breaks and removes soil ahead of the pipeline.

-

Pipe Installation: Hydraulic jacks located in the launch shaft push the pipe sections forward as excavation progresses.

-

Slurry Removal: Excavated soil is often transported back via a slurry system or conveyor belts.

-

Reception: Once the pipeline reaches the reception shaft, the operation is complete.

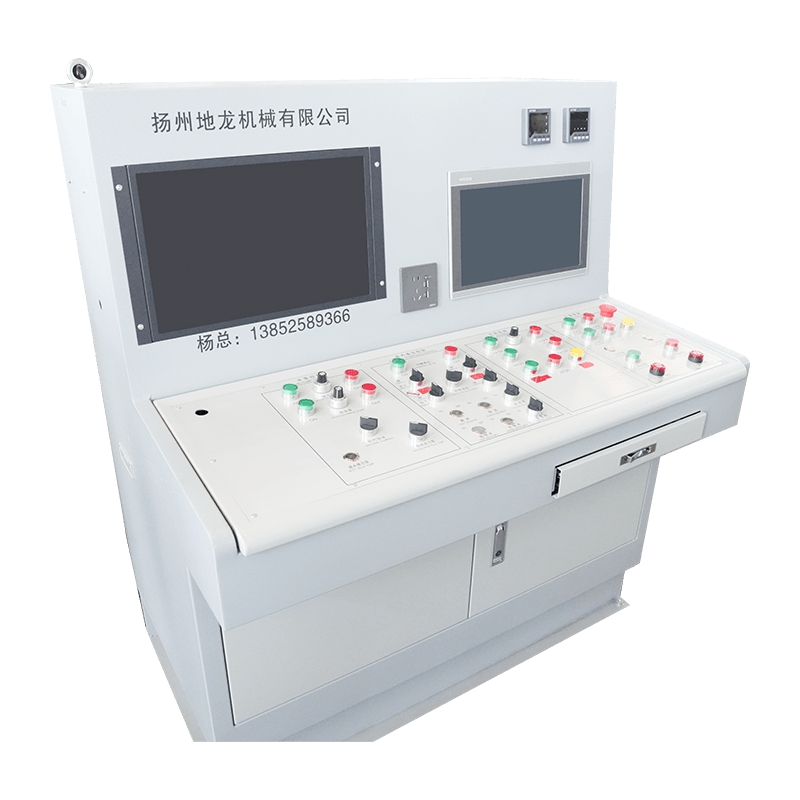

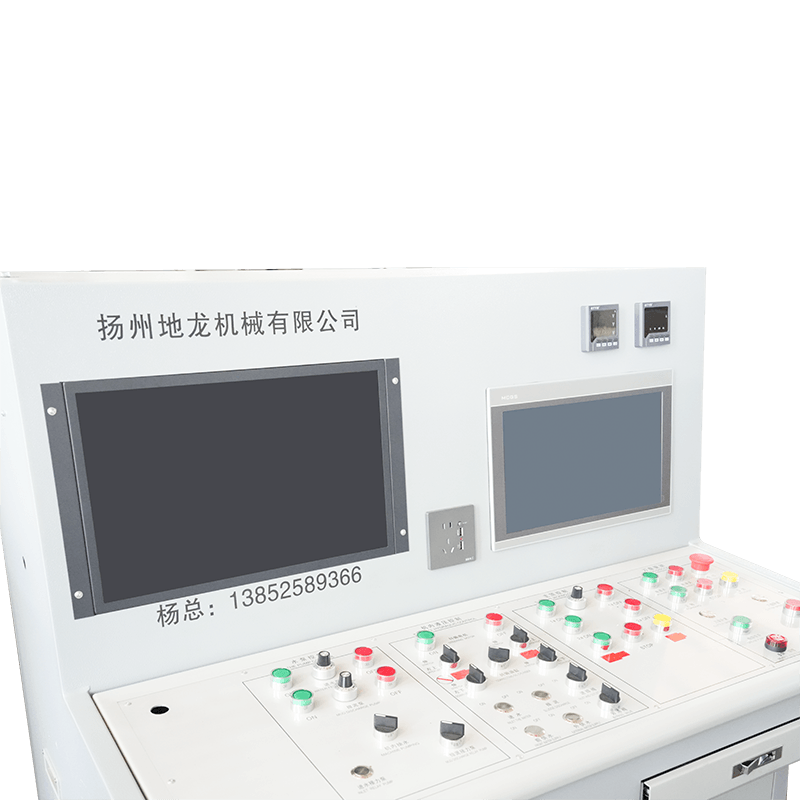

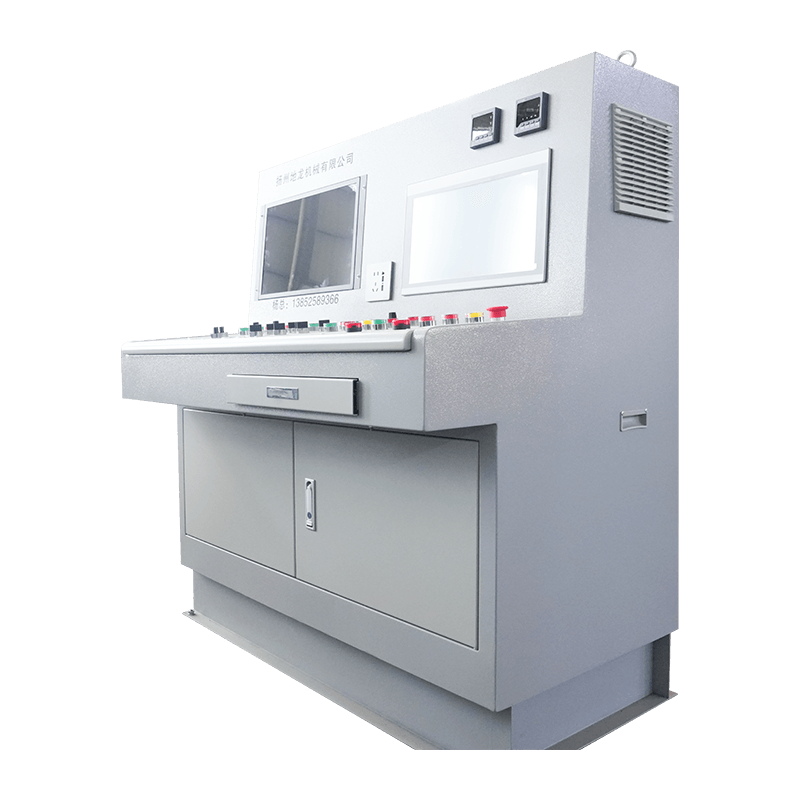

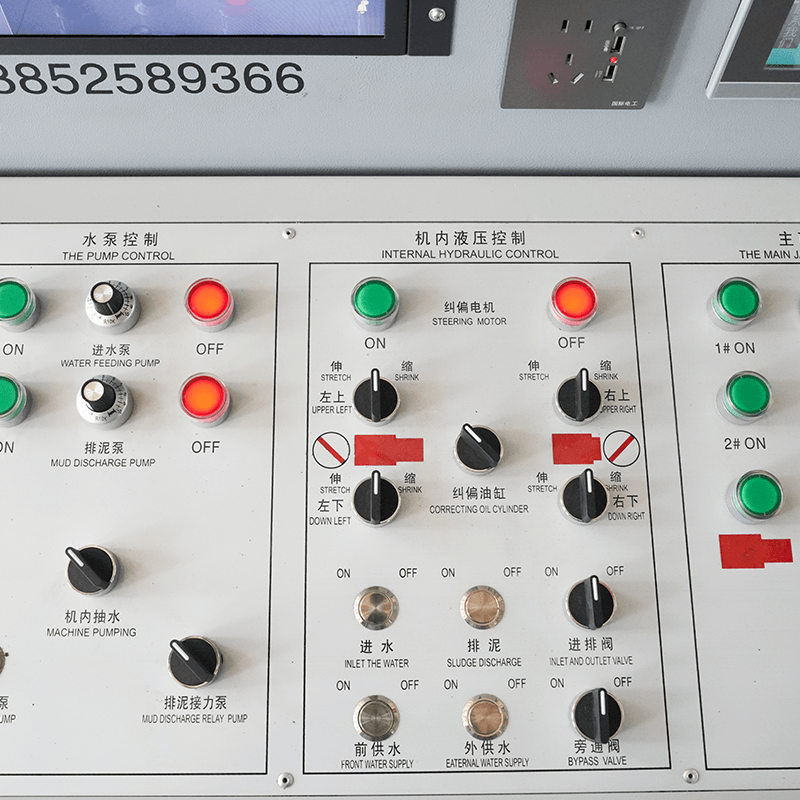

3. Key Components of a Pipe Jacking System

A typical pipe jacking machine includes the following components:

-

Cutter Head: Breaks and removes soil.

-

Shield/Slurry Machine: Supports the tunnel wall and may include slurry systems to transport debris.

-

Hydraulic Jacks: Provide the thrust needed to push the pipes.

-

Lubrication System: Injects bentonite or polymer to reduce friction between the pipe and soil.

-

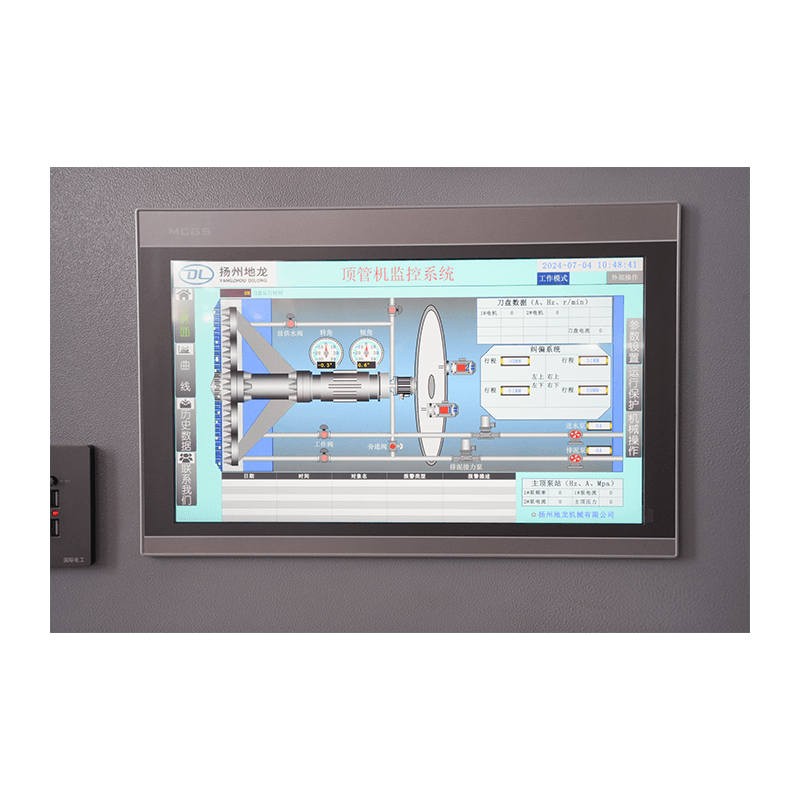

Control System: For steering and monitoring operations (especially in microtunneling machines).

-

Pipes: Reinforced concrete, steel, or HDPE pipes are commonly used depending on the project.

4. Applications of Pipe Jacking Machines

Pipe jacking is used in a wide range of underground construction projects, including:

-

Sewer and water pipelines

-

Stormwater drainage systems

-

Utility conduits (electricity, gas, telecom)

-

Railway and road underpasses

-

Culverts and pedestrian tunnels

Its ability to work without disturbing the ground surface makes it especially useful in cities and other sensitive areas.

5. Advantages of Pipe Jacking Machines

-

Minimal Surface Disruption: Ideal for working under roads, buildings, or railways.

-

Safe and Environmentally Friendly: Reduces noise, dust, and surface-level environmental impact.

-

High Accuracy: Modern systems offer precise steering and alignment.

-

Cost-Effective in Urban Areas: Saves costs on road excavation, traffic management, and reinstatement.

-

Versatile: Can work in various soil conditions including clay, sand, gravel, and even rock (with proper cutter heads).

6. Limitations and Challenges

-

Initial Cost: Equipment and setup are expensive compared to open-cut trenching.

-

Soil Conditions: Very hard soils or boulders can complicate operations.

-

Length Constraints: For very long distances, jacking force requirements increase.

-

Skilled Operation Required: Operators need technical knowledge and experience.

7. Future Trends in Pipe Jacking Technology

With growing urbanization, trenchless technologies like pipe jacking are expected to evolve rapidly. Innovations include:

-

Automation and AI Control Systems: For improved navigation and efficiency.

-

Advanced Real-Time Monitoring: Ensures safety and quality control during tunneling.

-

Eco-Friendly Lubricants: To reduce environmental impact.

-

Multi-Functional Machines: Capable of drilling, jacking, and laying pipe simultaneously.

Conclusion

The Pipe Jacking Machine represents a transformative technology in modern civil engineering. By enabling the underground installation of pipelines with minimal surface disturbance, it plays a vital role in expanding infrastructure while preserving the environment and urban life. As technology advances, pipe jacking is set to become even more efficient, versatile, and widely used across the globe.

If you're involved in construction, civil engineering, or urban planning, understanding how pipe jacking machines work and their benefits can help in choosing the right method for your underground infrastructure projects.

English

English  русский

русский  عربى

عربى