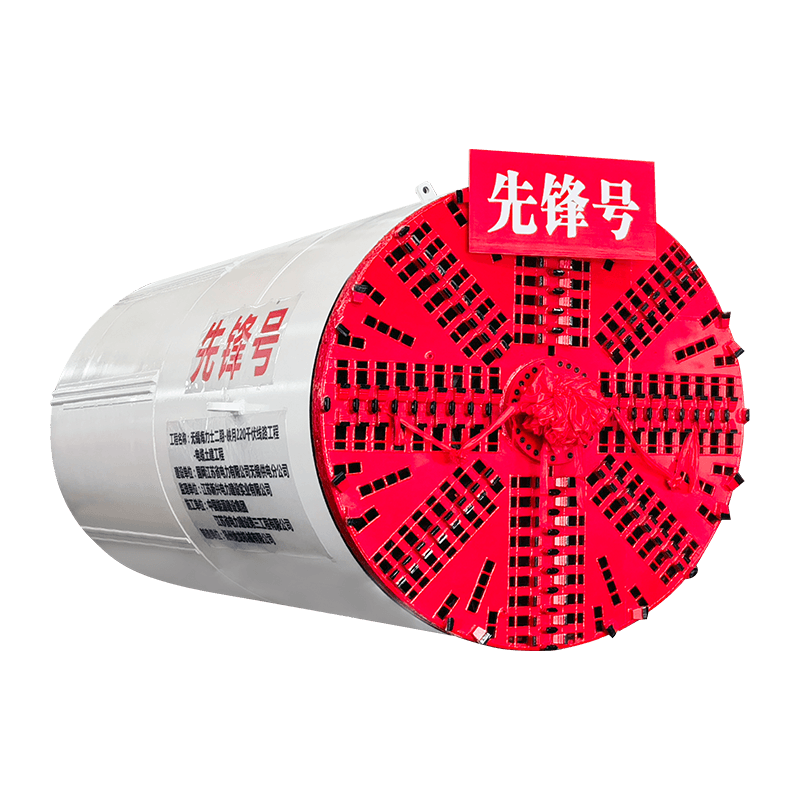

The slurry balance shield machine is a vital tool in the world of underground construction, especially for tunneling through soft ground and water-bearing soil. Known for its ability to maintain stability at the tunnel face, the slurry shield machine is widely used in metro projects, sewage systems, and under-river tunnels.

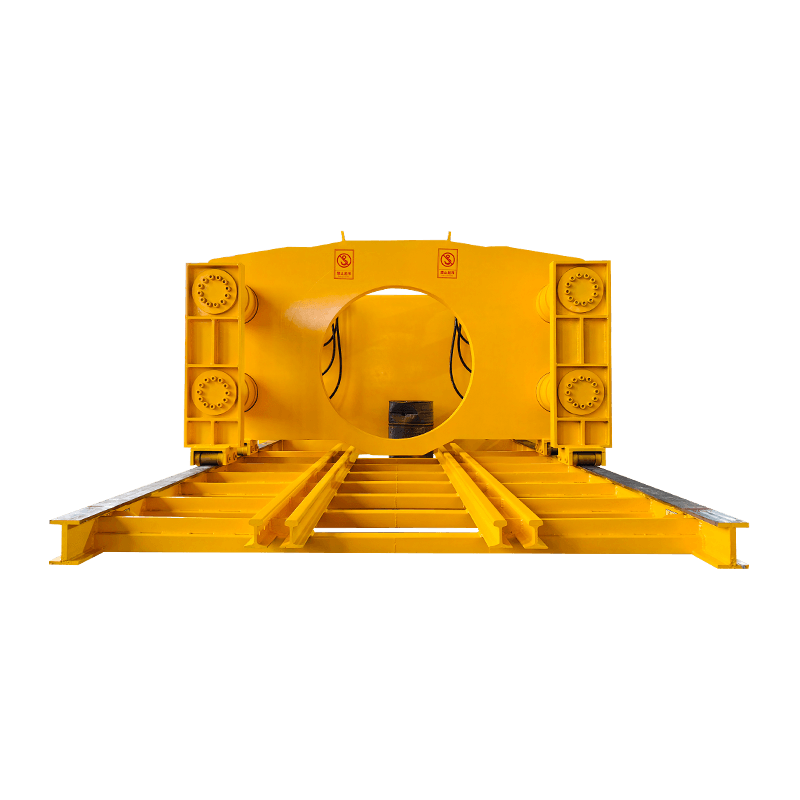

A slurry balance shield machine, also referred to as a slurry tunnel boring machine, is a type of TBM that uses pressurized slurry to balance earth and water pressure at the tunnel face. This machine is specifically designed for loose, unstable ground where traditional tunneling methods might fail. By injecting bentonite or polymer-based slurry into the working chamber, it prevents collapse and water ingress, making it ideal for challenging geological conditions.

How the Slurry Shield Machine Works

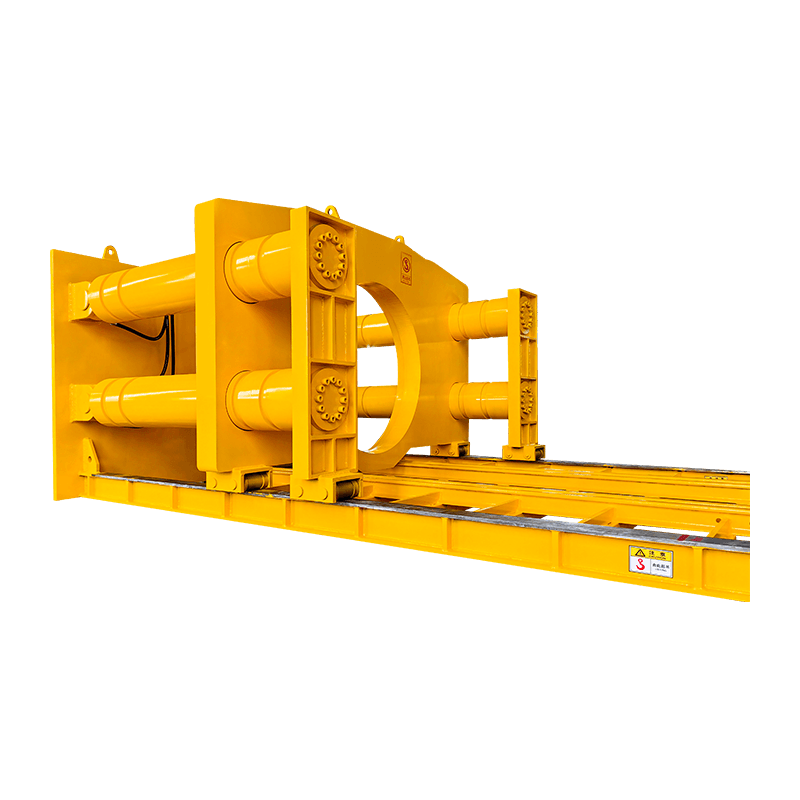

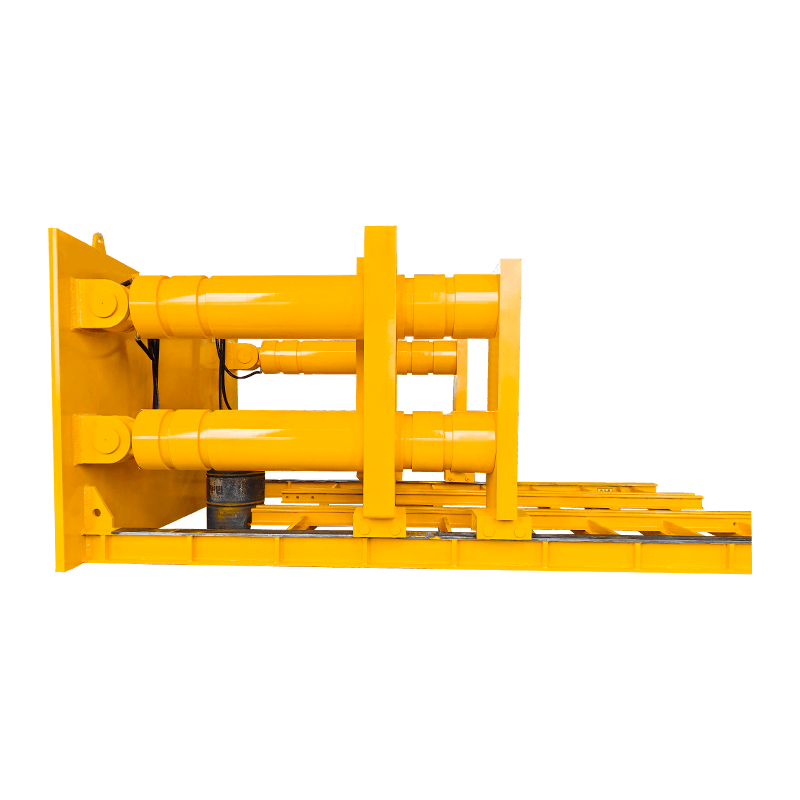

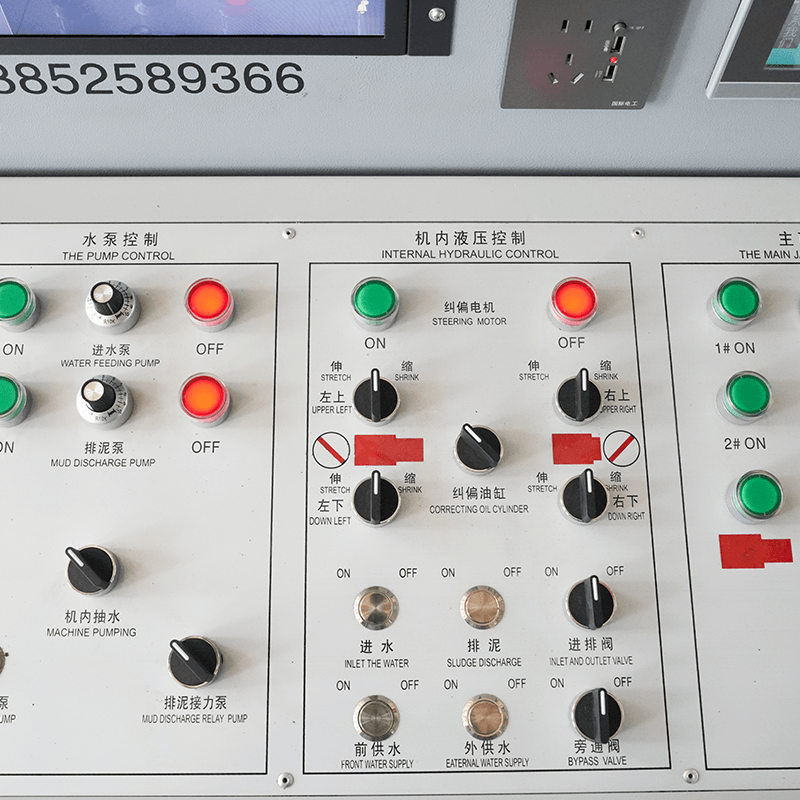

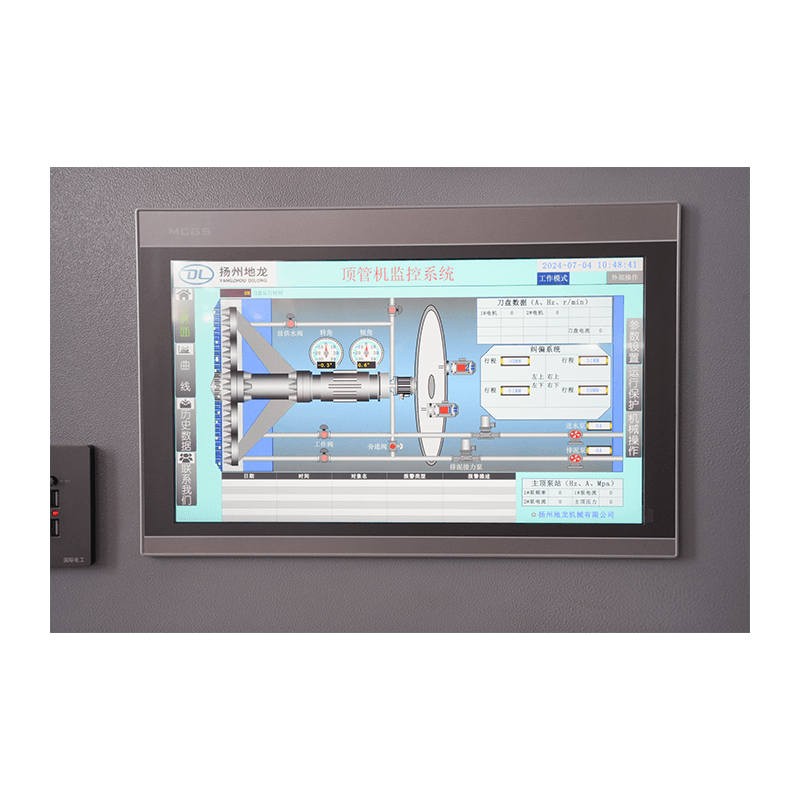

The slurry balance TBM operates by excavating soil using a rotating cutterhead. The loosened material is mixed with slurry and transported through pipelines to a separation plant on the surface. After separating soil and water, the clean slurry is pumped back into the tunnel face. This continuous loop ensures consistent pressure, which stabilizes the excavation and minimizes settlement on the surface.

Applications of the Slurry Pressure Balance TBM

The slurry pressure balance shield machine is widely applied in:

Urban subway projects

Underwater tunnels

Soft clay and silt terrains

High water-table regions

In cities like Tokyo, Shanghai, and London, the slurry tunnel boring machine has proven essential for constructing deep, safe tunnels in densely populated areas.

Advantages of the Slurry Shield Machine

One of the primary benefits of the slurry balance shield machine is its ability to work in highly saturated soil without compromising structural integrity. Other key advantages include:

High excavation accuracy

Reduced surface subsidence

Minimized environmental impact

Efficient muck removal through slurry pipelines

These advantages make the slurry pressure balance TBM an indispensable part of many large-scale infrastructure projects.

Slurry System and Soil Separation

A major component of the slurry shield tunneling machine is the slurry circulation and separation system. The separation plant filters out excavated soil from the slurry, ensuring that only clean slurry is reused. This not only maintains system efficiency but also supports environmental sustainability by reducing waste and water usage.

Challenges and Maintenance

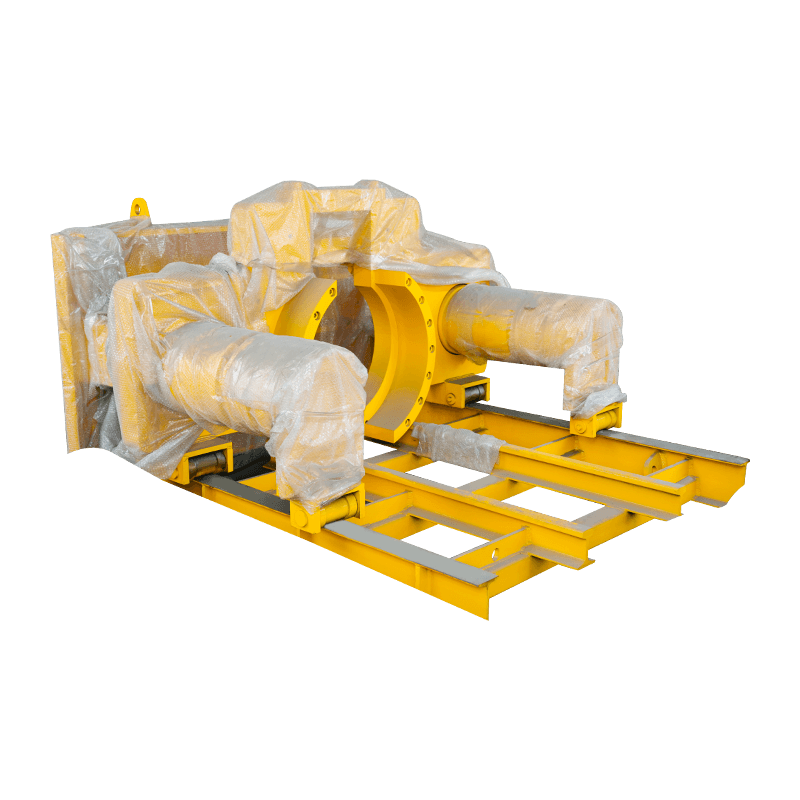

Despite its benefits, operating a slurry tunnel boring machine comes with challenges. These include the need for precise pressure control, proper maintenance of slurry pipelines, and handling abrasive soil that can wear out the cutterhead. Regular inspections and the use of wear-resistant materials can extend the life of the slurry balance TBM and ensure smooth operations.

English

English  русский

русский  عربى

عربى