In the modern era of urban development and infrastructure expansion, micro-tunneling machines have become essential tools for underground construction. This advanced trenchless technology is widely used for laying pipelines, cables, and conduits beneath roads, railways, and densely populated areas—without disrupting surface activity. Often referred to as microtunneling equipment, these machines are at the forefront of precision, safety, and environmental preservation in subsurface engineering.

What Is a Micro-Tunneling Machine?

A micro-tunneling machine is a remote-controlled, laser-guided excavation system designed for installing underground pipelines with extreme accuracy. It operates on the principle of pipe jacking, pushing prefabricated pipes behind the cutting head as excavation progresses. Unlike traditional tunneling methods, microtunneling eliminates the need for open trenches, making it ideal for urban and environmentally sensitive areas.

This type of tunneling machinery combines excavation, slurry transport, and pipe installation in a single automated process. It typically includes a micro-tunnel boring machine (MTBM), a control cabin, a jacking station, and slurry separation systems.

Advantages of Using Micro-Tunneling Machines

One of the key benefits of using micro-tunneling machines is their minimal surface disruption. This trenchless tunneling method is ideal for crossing busy roads, rivers, railways, and protected zones where traditional excavation is not feasible.

Here are some of the primary advantages:

Precision: The laser guidance system ensures accurate alignment.

Safety: Remote operation reduces human exposure to hazardous environments.

Environmentally friendly: Lower impact on surface activities and ecosystems.

Versatility: Suitable for various ground conditions including clay, sand, gravel, and rock.

Cost-effective: Reduced restoration costs from avoided surface disruption.

Applications of Microtunneling Equipment

Microtunneling machines are commonly used for:

Installing sewer and water pipelines

Laying electric and communication conduits

Constructing stormwater drainage systems

Creating underground utility crossings

These machines are particularly useful in projects requiring deep installations or where soil conditions vary significantly. Their ability to maintain precise control over alignment and grade is unmatched in the world of trenchless excavation.

Components of a Micro-Tunneling System

A complete micro-tunneling system includes several critical components:

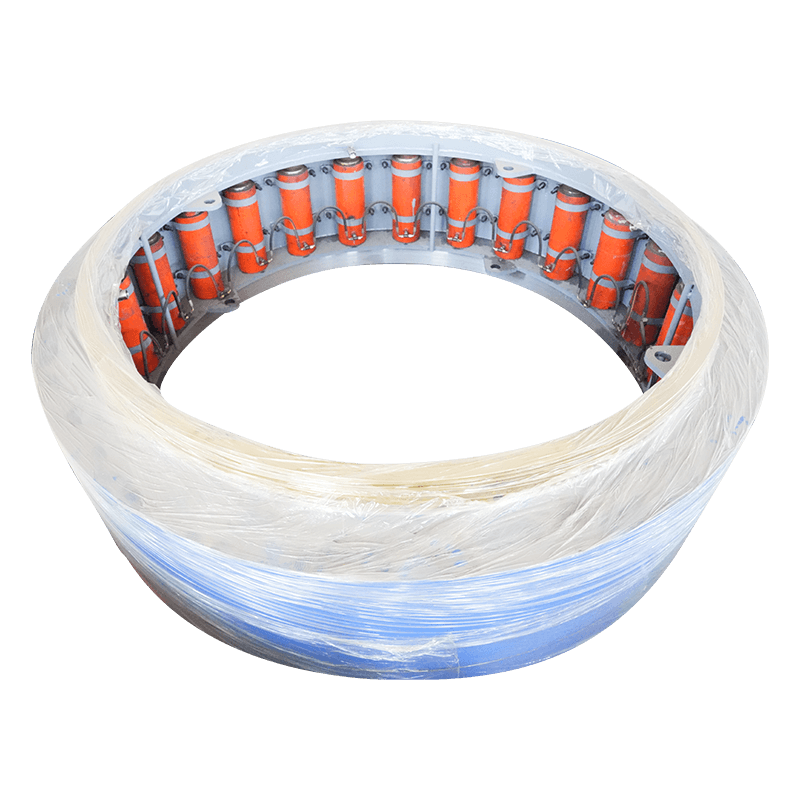

MTBM (Micro Tunnel Boring Machine): The cutting head that performs the excavation.

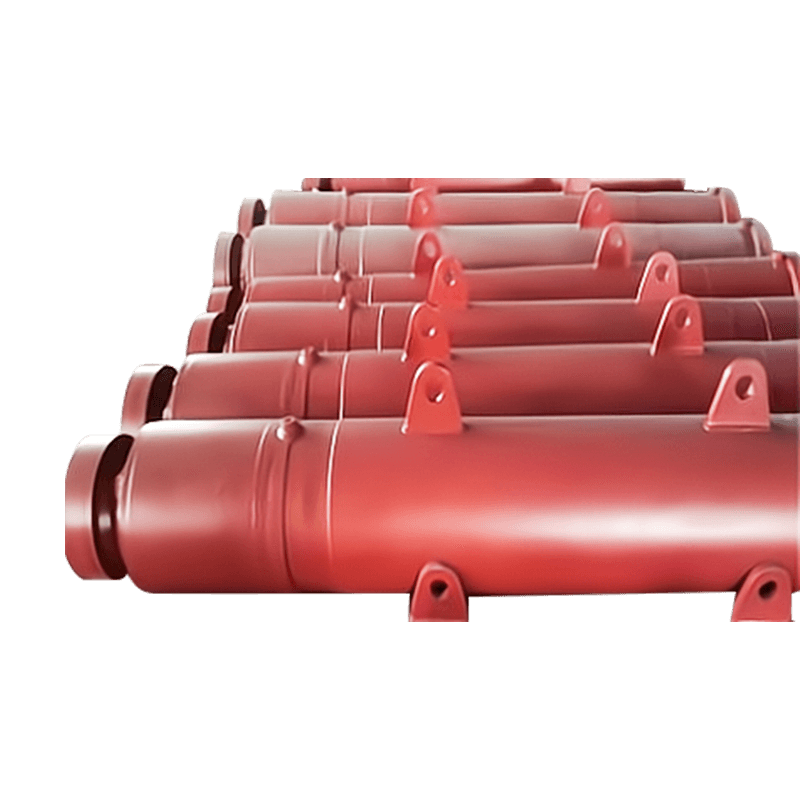

Pipe Jacking Station: Uses hydraulic jacks to push pipes through the borehole.

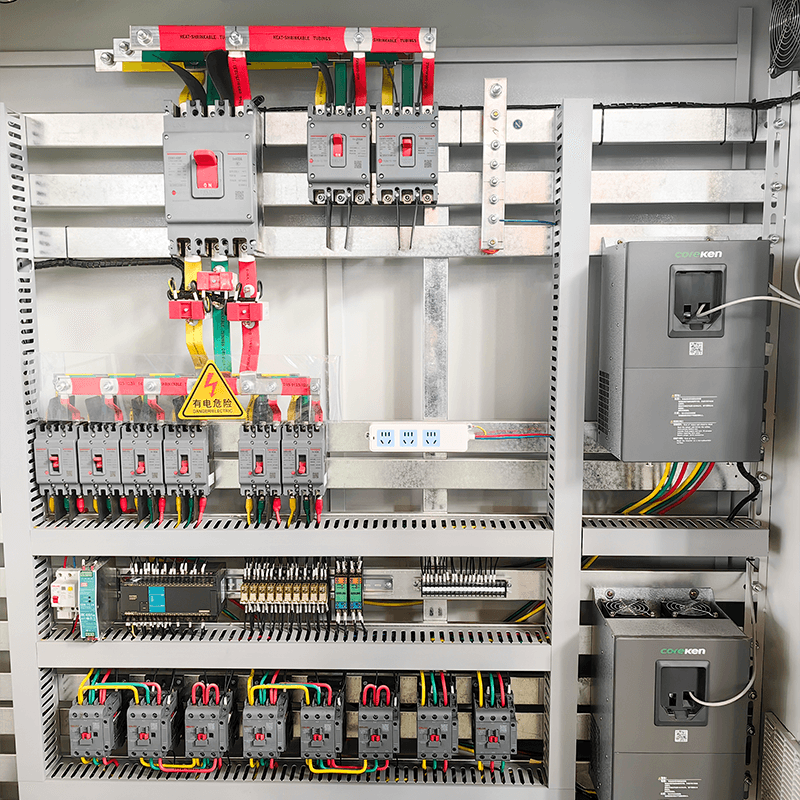

Control Cabin: Where operators monitor and control the machine remotely.

Slurry System: Transports excavated material to the surface for separation and disposal.

Lubrication System: Reduces friction during pipe jacking.

Each of these components works in synchronization to ensure efficient and accurate boring and pipe installation.

Choosing the Right Micro-Tunneling Machine

When selecting a micro-tunneling machine, several factors must be considered, including bore diameter, ground conditions, pipe material, and project length. Reputable manufacturers offer machines tailored for different diameters and terrains, whether it’s soft soil or hard rock. Choosing the right microtunneling equipment can significantly affect project timelines and budgets.

English

English  русский

русский  عربى

عربى