The pipe jacking machine is an essential piece of equipment in modern underground construction. Also known as a microtunneling machine, tunnel boring machine, or trenchless tunneling equipment, this advanced system plays a crucial role in the installation of pipelines without disrupting surface infrastructure. With the growing demand for urban development and minimal environmental impact, pipe jacking technology has become a preferred method for constructing underground passages for sewage, drainage, water supply, and cable ducts.

A pipe jacking machine is a specialized tunneling device designed to push pre-fabricated concrete, steel, or other types of pipes through the ground horizontally. It operates from a launch shaft, pushing the pipeline forward using hydraulic jacks while simultaneously excavating the soil ahead. This process is known as trenchless construction, as it avoids the need for open-cut trenches on the surface, thereby preserving existing roads, railways, and buildings.

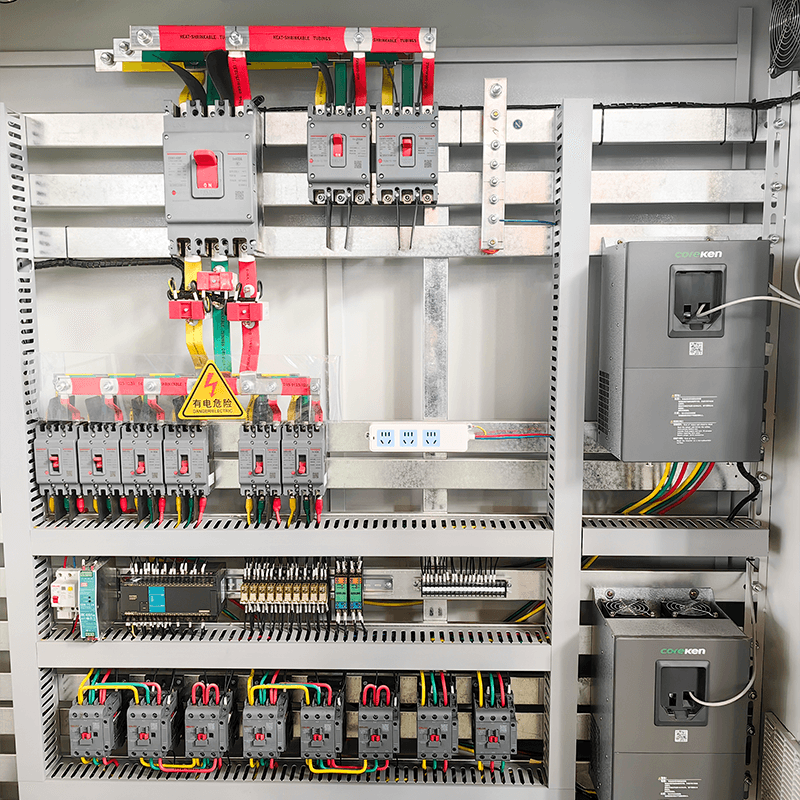

The pipe jacking system typically includes a jacking frame, hydraulic cylinders, cutting head, spoil removal system, and a guidance system to ensure precise alignment. Some systems are remotely controlled, allowing operators to guide the tunneling machine from a safe distance with high accuracy.

Applications of Pipe Jacking Machines

Pipe jacking machines are widely used in a variety of civil engineering and municipal infrastructure projects. Some common applications include:

Sewer pipeline installation

Stormwater drainage tunnels

Utility and communication cable ducts

Water mains and pressure pipelines

Culverts under highways and railroads

In densely populated urban environments, trenchless tunneling equipment is particularly valuable. It allows contractors to install pipelines with minimal disruption to traffic and local businesses. Moreover, pipe jacking is ideal for challenging soil conditions, high groundwater levels, and areas with sensitive surface structures.

Advantages of Using Pipe Jacking Technology

There are several advantages to using pipe jacking equipment over traditional open-cut methods:

Minimal Surface Disruption

Since the operation is entirely underground, there is little to no disturbance to the surface environment. This makes it suitable for city centers, industrial areas, and heritage zones.

Higher Precision and Safety

With the integration of advanced guidance systems, microtunneling machines achieve excellent alignment accuracy, reducing the risk of deviations and costly errors.

Environmental Benefits

The trenchless approach reduces noise, dust, and vibration, making it more environmentally friendly and less invasive to nearby communities.

Cost-Effective for Long Distances

While the initial investment in a pipe jacking machine may be higher, the reduced need for surface restoration and shorter project timelines often result in long-term savings.

Adaptability

Pipe jacking can be used in a variety of ground conditions, including clay, sand, gravel, and even rock. This versatility makes it a go-to solution for complex tunneling needs.

Key Components of a Pipe Jacking Machine

A modern pipe jacking machine consists of several integrated components:

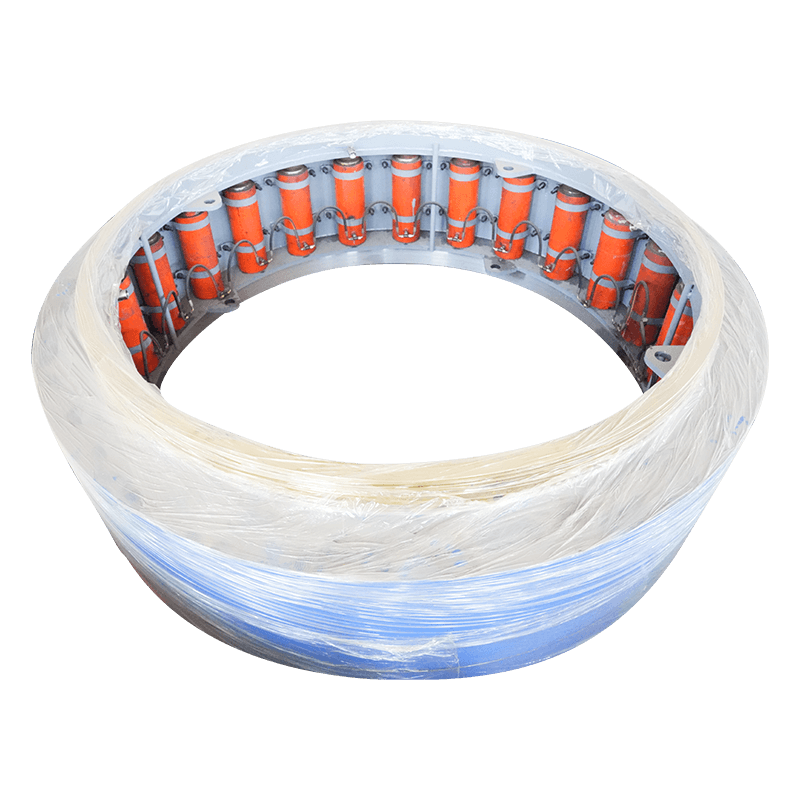

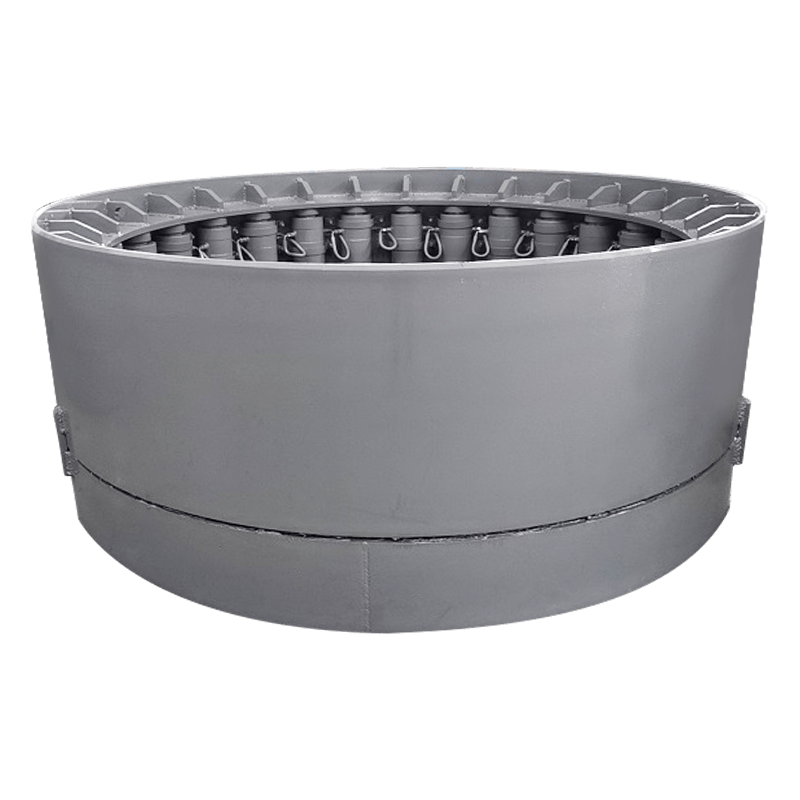

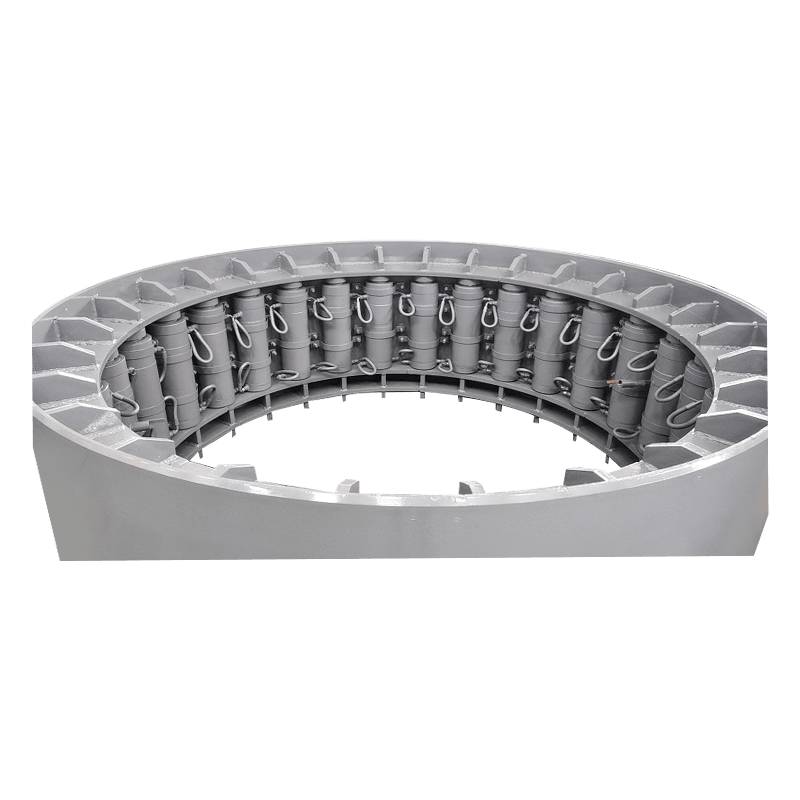

Cutter head: Excavates the soil at the front of the pipeline.

Hydraulic jacks: Push the pipeline segments into place.

Spoil removal system: Transports excavated material to the surface.

Laser guidance system: Ensures precise directional control.

Control cabin: Allows operators to monitor and adjust parameters in real-time.

In some cases, the pipe jacking process is combined with slurry or earth pressure balance technology to handle high-pressure ground conditions, further expanding its usability.

English

English  русский

русский  عربى

عربى