The Slurry Balance Shield Machine, often referred to as a slurry balance tunnel boring machine or pressurized face TBM, represents a state-of-the-art solution for underground tunneling in complex geological environments. These machines are vital in safely navigating soft ground, high groundwater, and unstable soil layers.

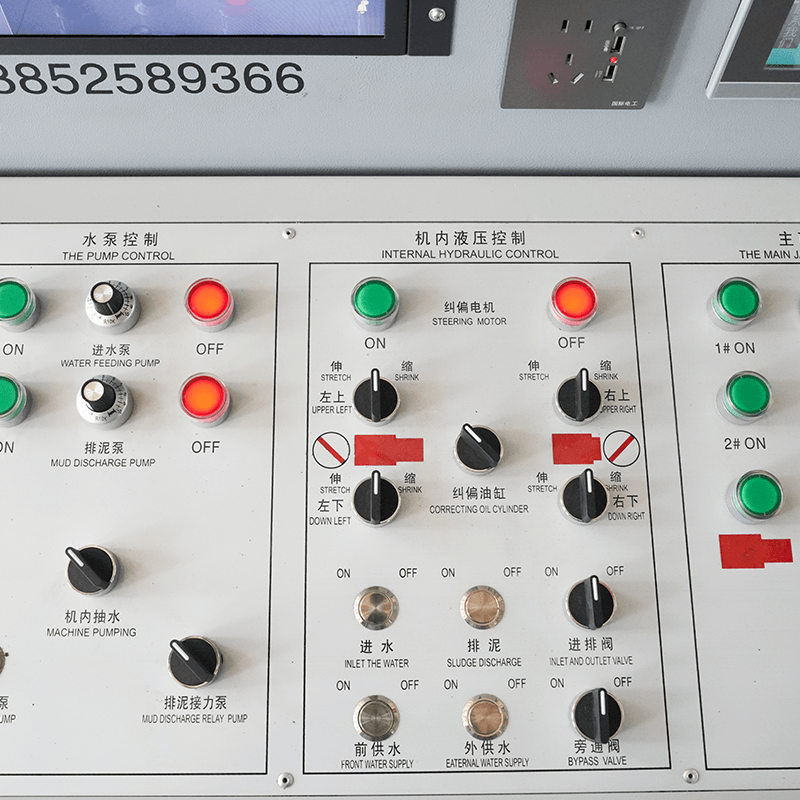

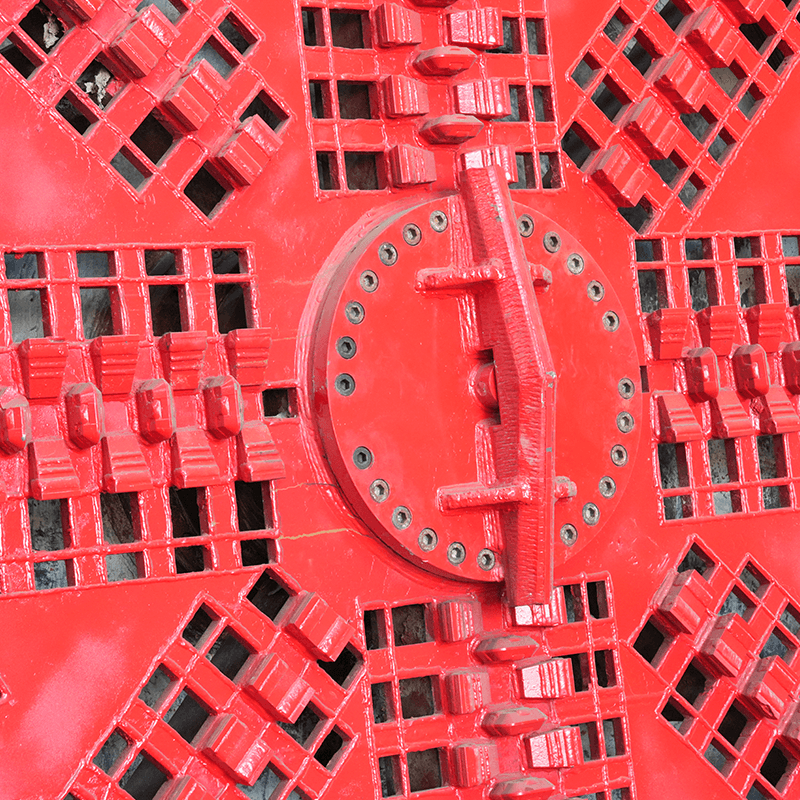

The working principle of a slurry balance shield machine revolves around using pressurized slurry to stabilize the tunnel face. During excavation, bentonite-based slurry is pumped into the cutting chamber to balance earth pressure and water inflow. This pressurized medium supports the tunnel face, preventing collapse or excessive deformation. Meanwhile, the excavated soil is mixed with slurry and transported through pipelines to a separation plant on the surface, where solid and liquid are efficiently separated.

One of the major benefits of this system is face pressure control. By adjusting the slurry pressure, operators can respond to changing ground conditions in real time. This makes the slurry shield TBM suitable for soft clay, silt, sand, and gravel formations, even in urban areas with adjacent buildings and underground utilities.

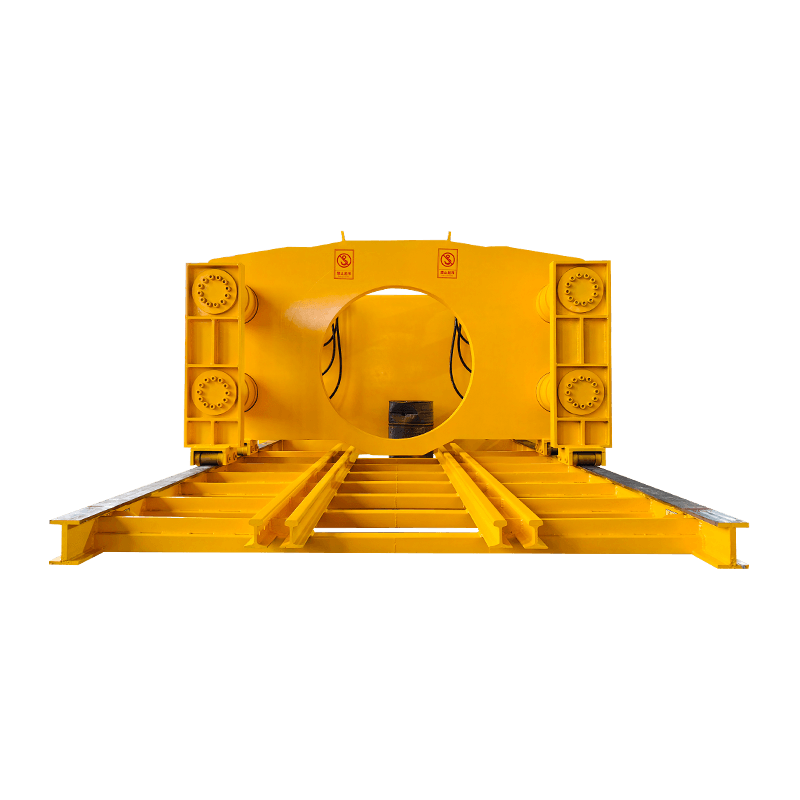

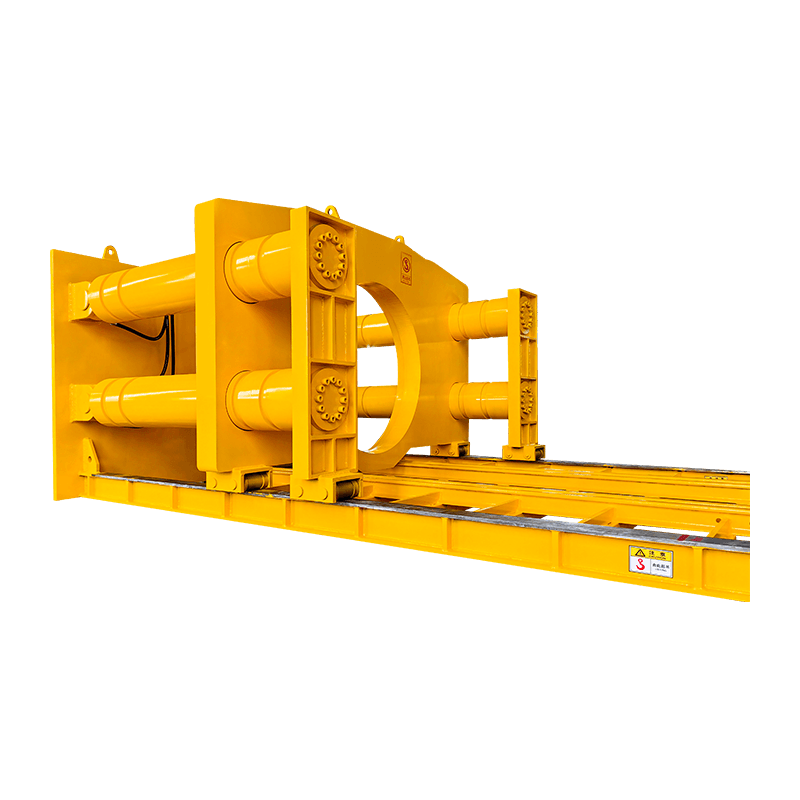

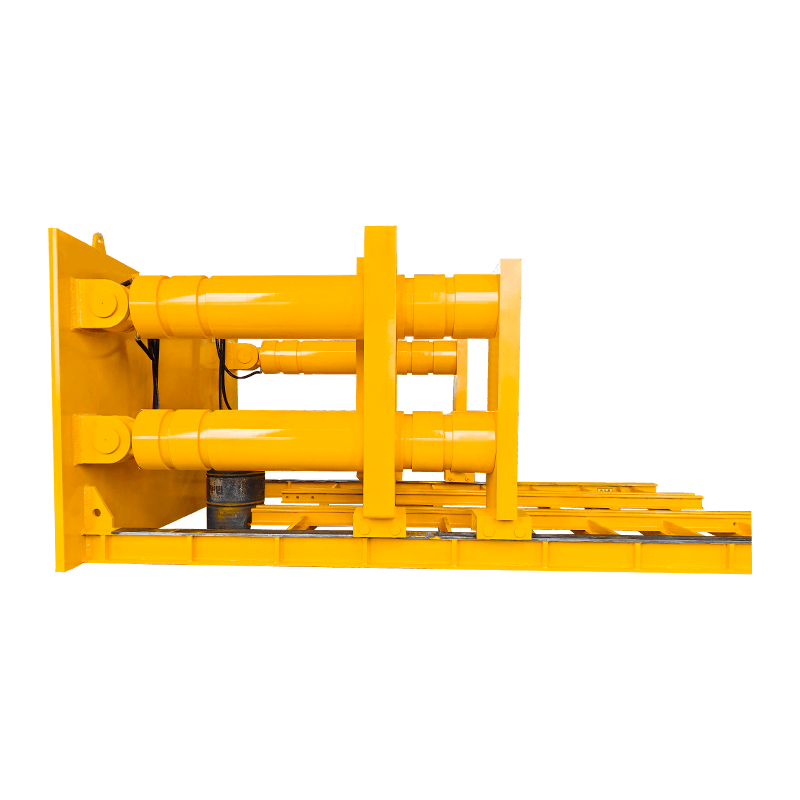

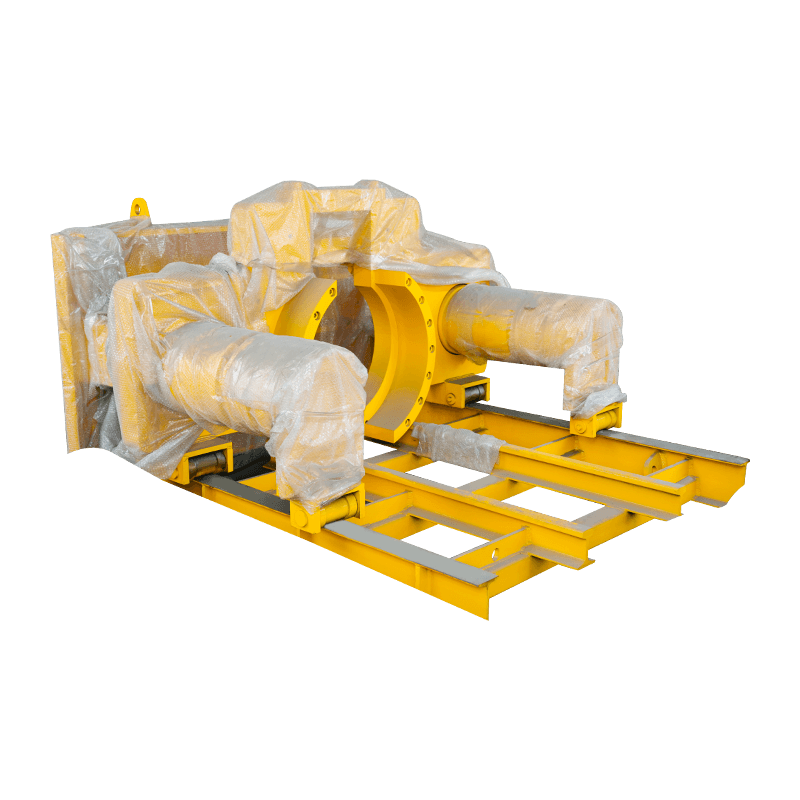

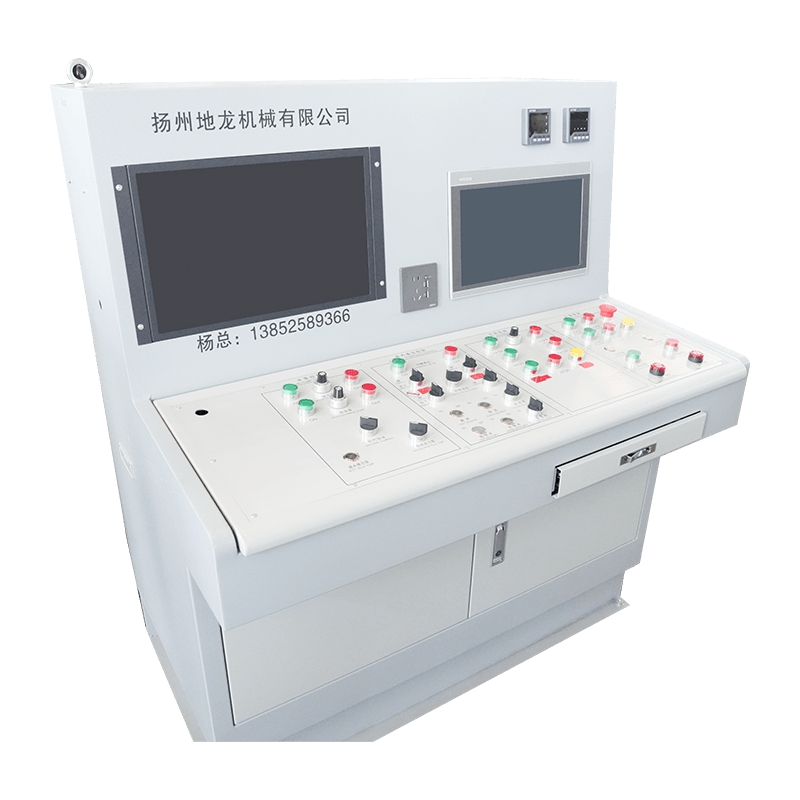

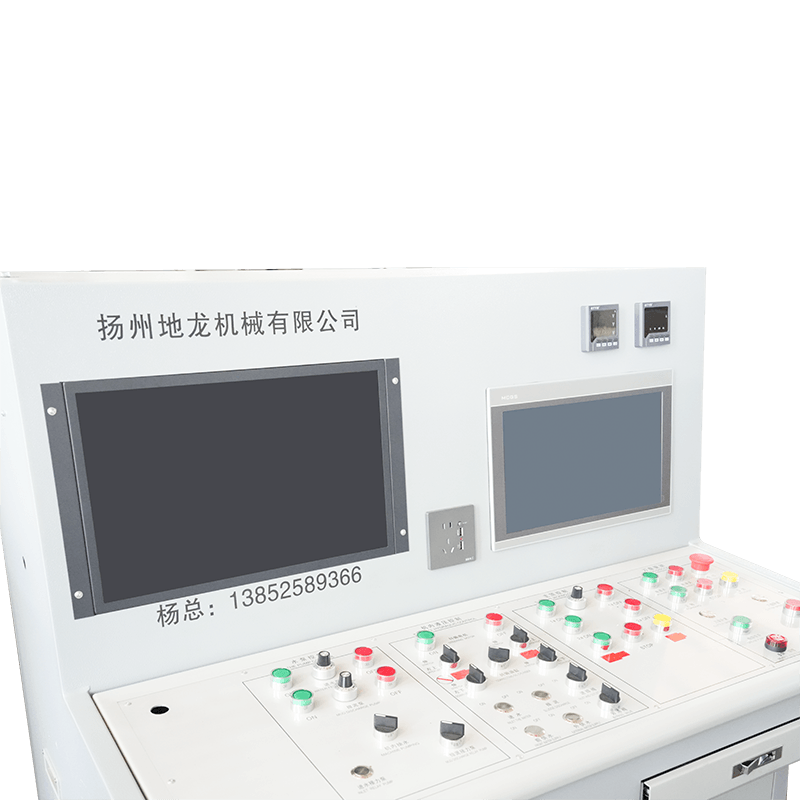

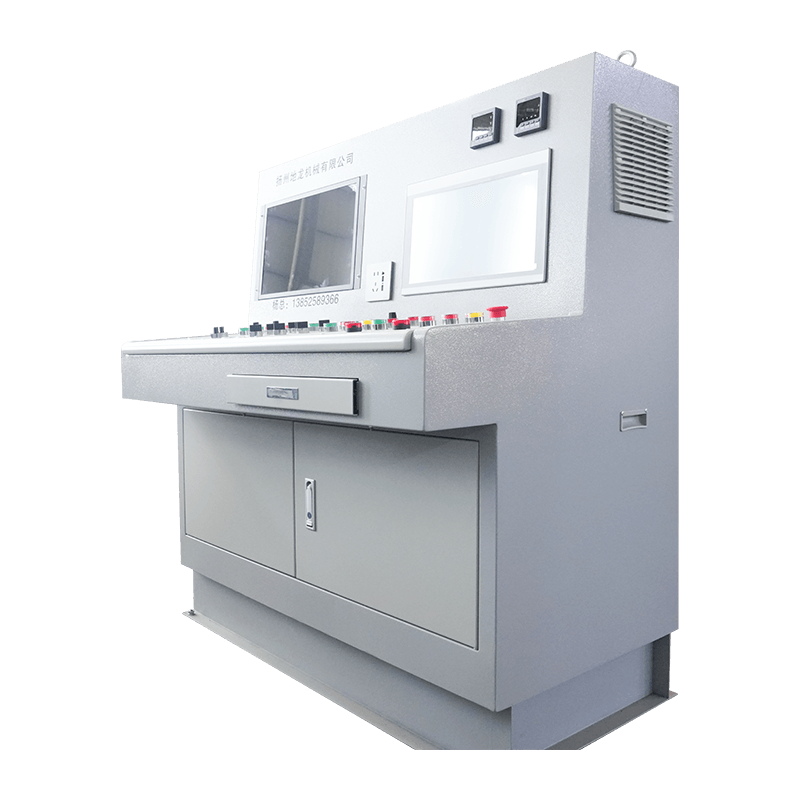

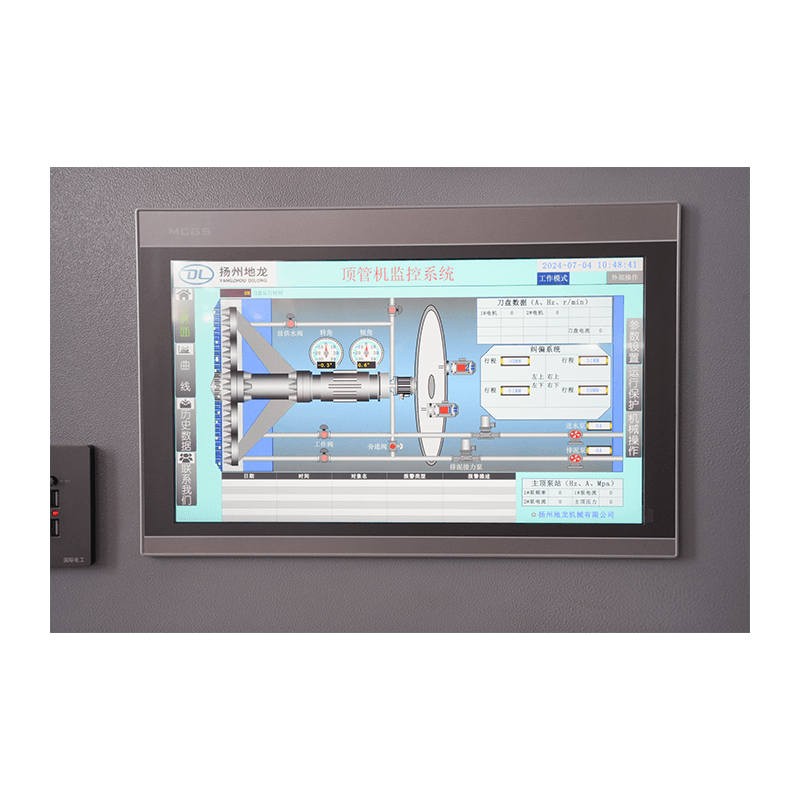

In terms of equipment design, modern slurry balance tunnel boring machines come with advanced navigation systems, high-efficiency cutter heads, and integrated slurry circulation systems. These features allow for accurate alignment, reduced downtime, and improved operational safety. Additionally, noise and vibration levels are significantly lower compared to traditional open-cut methods, contributing to a more sustainable construction process.

The versatility of slurry balance shield machines extends to a variety of infrastructure projects: subway tunnels, drainage systems, utility corridors, and even cross-sea or river tunnels. Their adaptability to complex geological challenges and minimal environmental footprint make them indispensable in modern civil engineering.

As technology evolves, so does the performance of slurry shield tunneling machines. Innovations in automation, data monitoring, and slurry treatment continue to enhance their efficiency and reliability. For engineers and construction firms looking to execute safe, clean, and efficient underground projects, the slurry balance shield machine remains a top-tier choice.

English

English  русский

русский  عربى

عربى