Tunnel Boring Machines (TBMs) are sophisticated pieces of equipment that have revolutionized underground construction. They are essentially mobile factories designed to excavate tunnels with minimal disturbance to the surrounding ground.

How TBMs Work: The Fundamental Process

The core operation of a TBM involves several continuous steps:

-

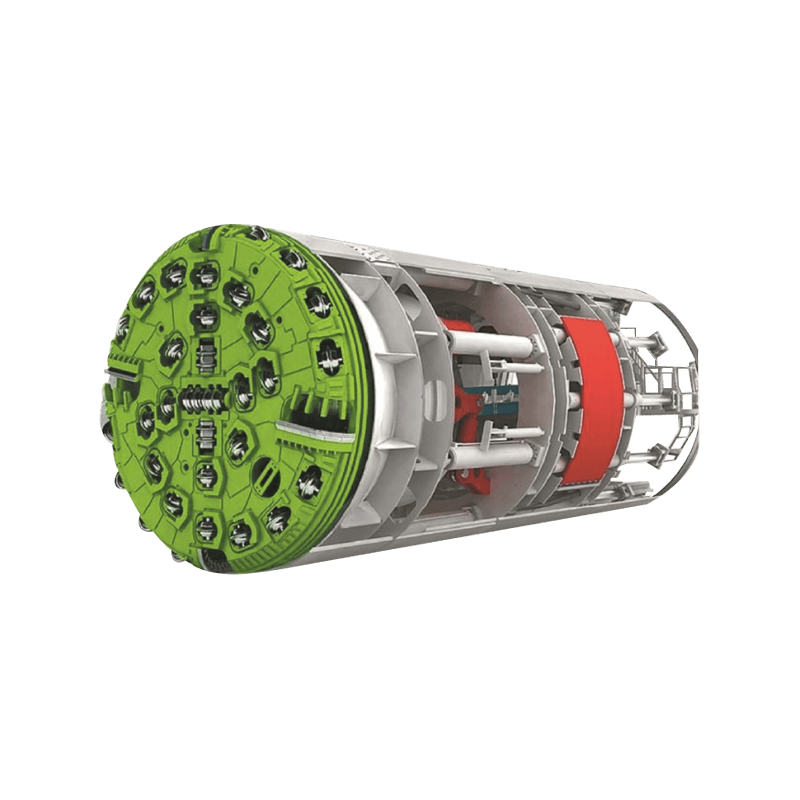

Excavation: At the very front of the TBM is a massive, rotating cutter head. This steel disk is fitted with various cutting tools, such as disc cutters for hard rock or cutter bits and scrapers for softer ground. As the cutter head rotates, it grinds, scrapes, or shears the material at the tunnel face.

-

Muck Removal: The excavated material, known as "muck," falls through openings in the cutter head into a chamber. From there, it's typically transported by a screw conveyor (for soft ground TBMs) or loaded onto a series of conveyor belts (for hard rock TBMs) that run the length of the tunnel. This muck is then continuously removed to the surface for disposal or recycling.

-

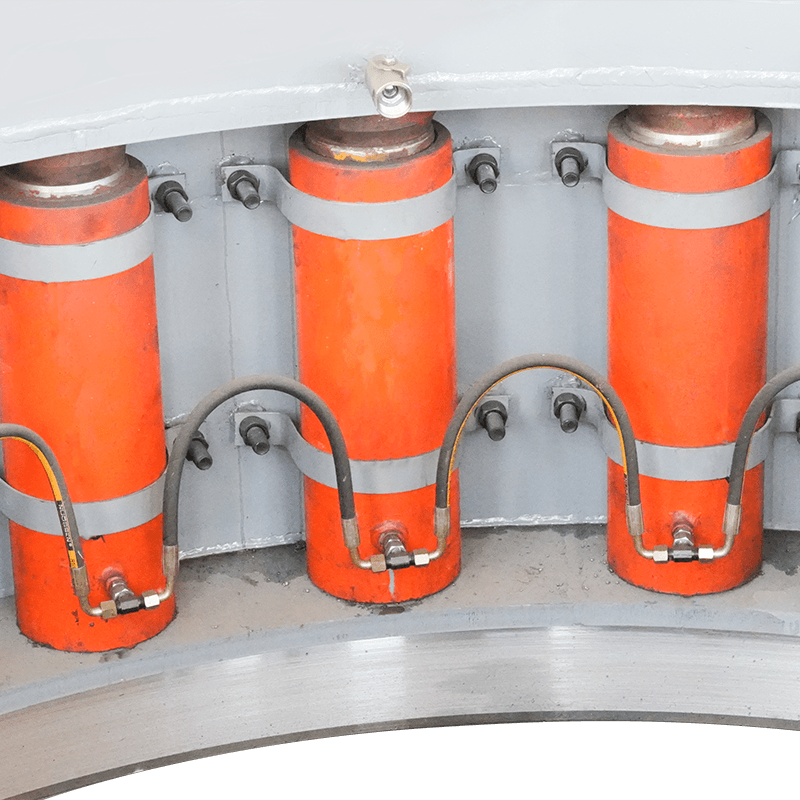

Thrust and Advance: The TBM is propelled forward by powerful thrust cylinders (jacks) located behind the cutter head. These cylinders push off against the previously installed tunnel lining segments, creating the necessary force to advance the cutter head into the ground.

-

Tunnel Lining Installation: Immediately behind the cutter head, within the protective shell of the TBM (the shield), lies the erector. This robotic arm picks up precast concrete segments (typically curved, trapezoidal pieces) and meticulously places them to form a complete ring of the tunnel lining. These segments are bolted together, creating a strong, watertight, and permanent structure that supports the ground and forms the finished tunnel wall.

-

Grouting: Once a ring of segments is installed, the void between the outside of the segments and the excavated ground (the "tail void") is immediately filled with a specialized grout. This grout solidifies, providing additional support to the tunnel lining, preventing ground settlement, and ensuring a tight fit.

-

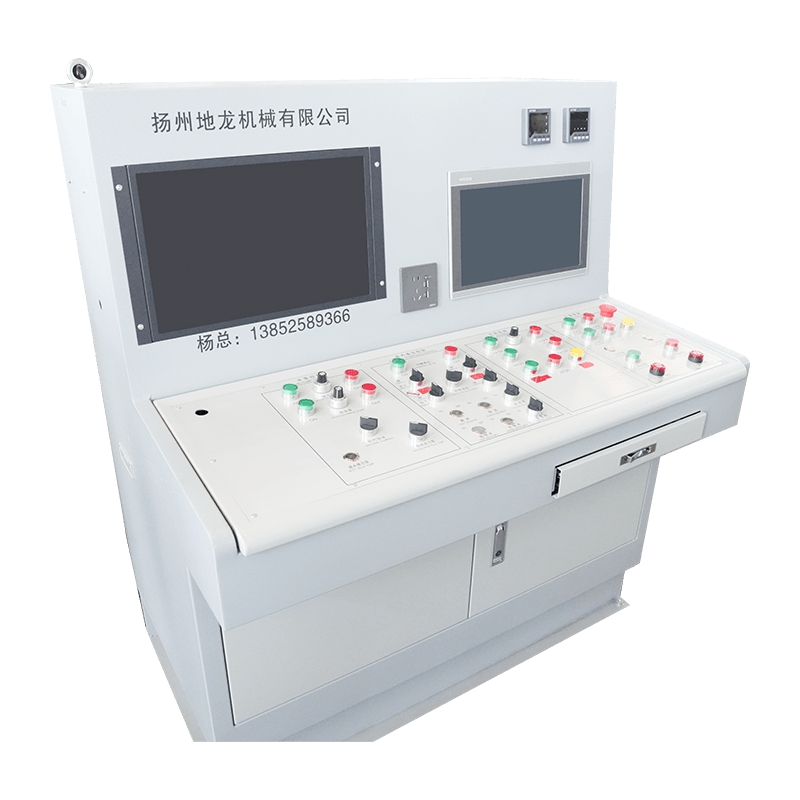

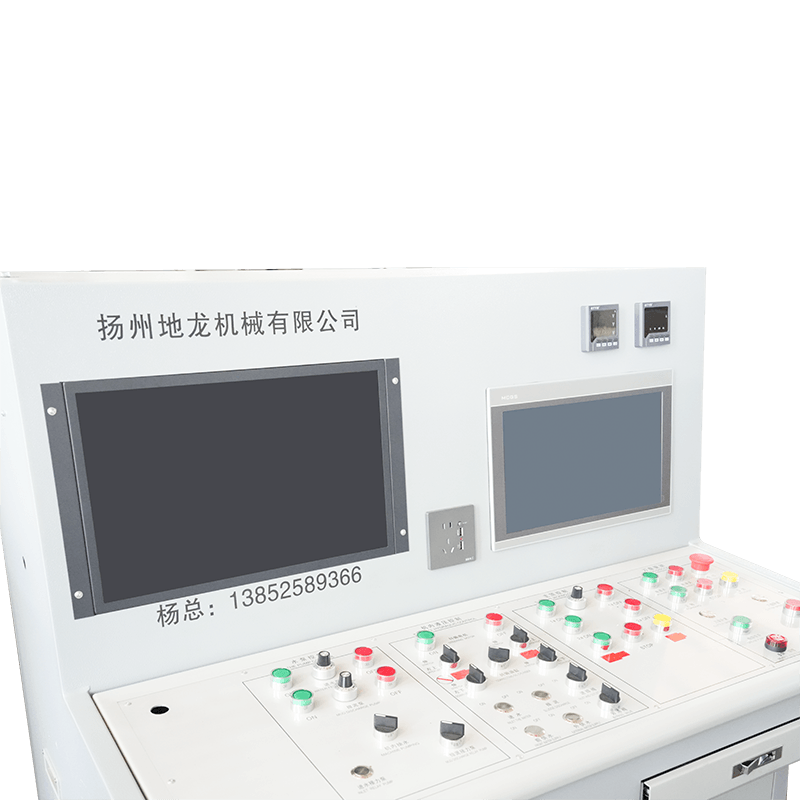

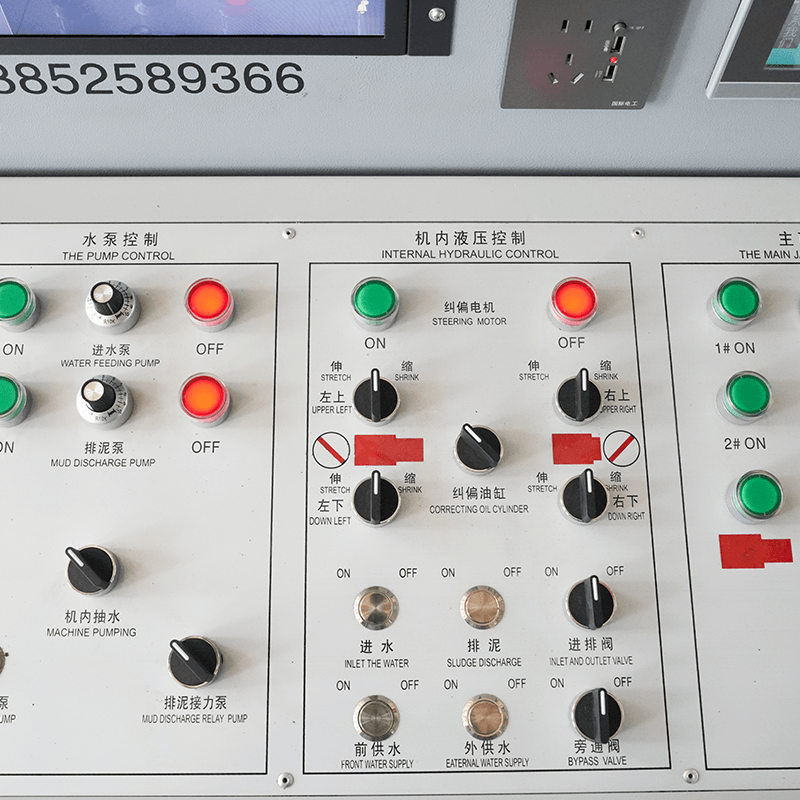

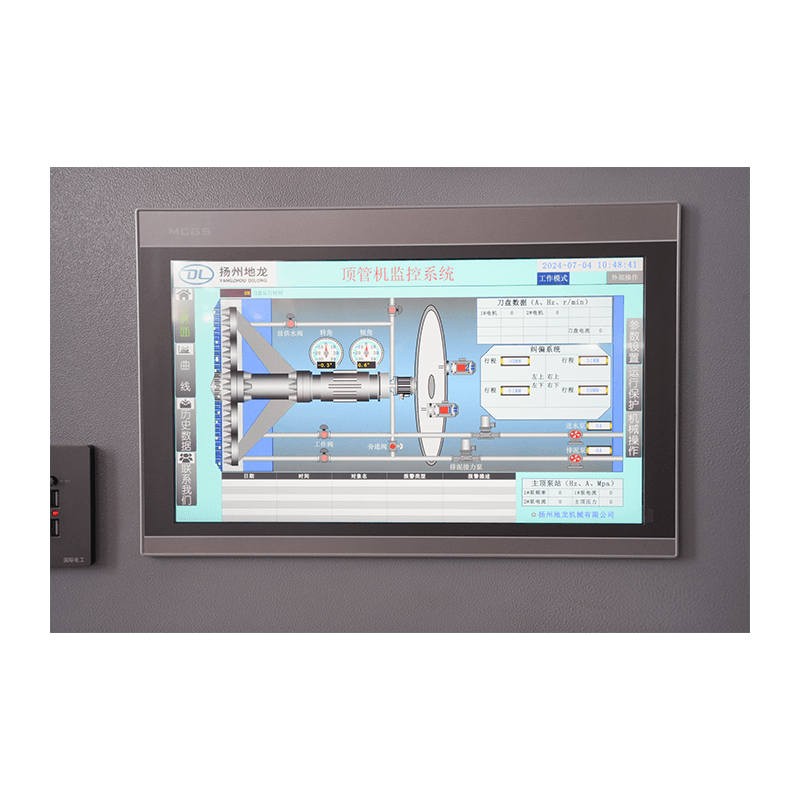

Steering and Navigation: TBMs are equipped with sophisticated laser guidance systems and surveying instruments. Operators can precisely control the direction of the TBM by adjusting the thrust of individual jacks, varying the rotation speed of the cutter head, or using articulation joints within the machine. This allows them to maintain the planned alignment and gradient, even navigating curves.

-

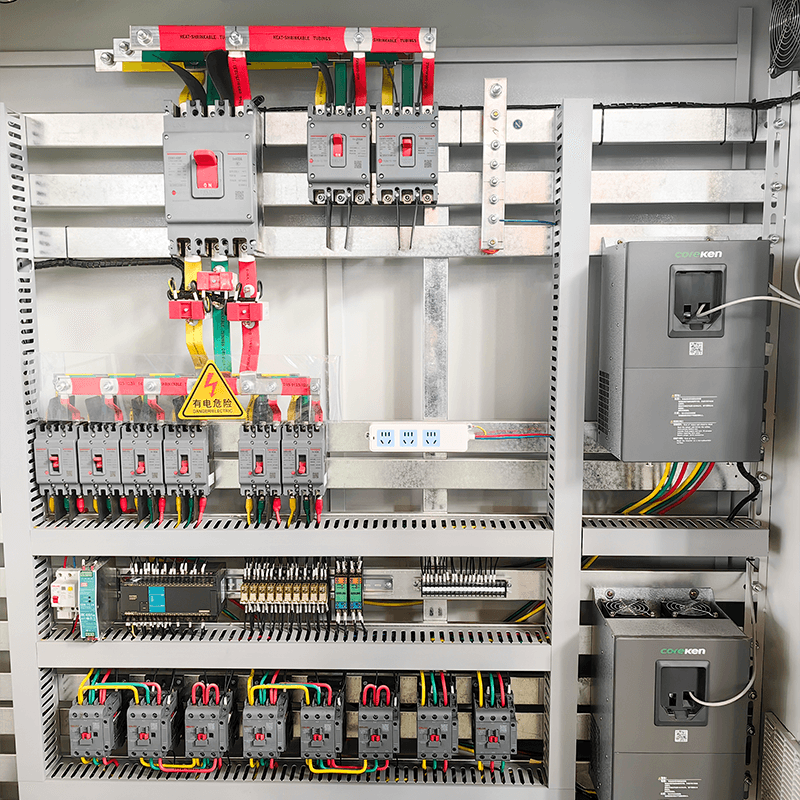

Trailing Gear (Back-up System): Behind the main TBM body, a series of articulated gantries or trailers (the "back-up system") follows. This trailing gear houses essential support systems, including:

- Power supply and control rooms

- Ventilation systems

- Muck removal conveyors

- Grout pumps and mixing plants

- Water and utility lines

- Personnel access and safety equipment.

Types of TBMs and Their Applications

The choice of TBM type is critical and depends heavily on the geological conditions of the ground to be tunneled:

-

Hard Rock TBMs (Open-Gripper TBMs / Shielded Hard Rock TBMs): These TBMs are designed for solid rock formations. They use disc cutters that create micro-fractures in the rock face.

- Open-Gripper TBMs: Advance by gripping against the tunnel walls (rock) with gripper pads.

- Shielded Hard Rock TBMs: Used when rock conditions are fractured or mixed, providing full ground support with a shield and often installing a segment lining.

-

Earth Pressure Balance (EPB) TBMs: Ideal for soft, cohesive soils (clay, silt, sand) that can stand without support for a short period. An EPB TBM uses the excavated material itself to create a "muck cake" that applies pressure to the tunnel face, balancing the surrounding ground pressure. A screw conveyor regulates the removal of muck while maintaining this balance.

-

Slurry TBMs: Best suited for loose, water-bearing soils (sands, gravels, saturated ground). In a Slurry TBM, the cutter head operates in a pressurized slurry-filled chamber. The slurry stabilizes the tunnel face and transports the excavated material to the surface through pipes, where it's processed to separate the solids from the liquid.

-

Mixed Ground TBMs (Variable Density TBMs): These are versatile machines that can adapt to varying ground conditions, sometimes combining features of EPB and Slurry TBMs. They can adjust parameters like face pressure and muck removal rates to suit the changing soil properties encountered.

-

Pipe Jacking Machines (Microtunneling TBMs): Smaller versions of TBMs, often remote-controlled, used for installing pipelines or smaller utility conduits. They push pipes directly behind the cutter head.

Advantages of Using TBMs

- Speed and Efficiency: TBMs can bore continuously and generally excavate tunnels much faster than conventional methods like drilling and blasting.

- Safety: The enclosed shield of the TBM provides a safer working environment for personnel, protecting them from collapses and groundwater ingress.

- Minimal Surface Disturbance: As they operate underground, TBMs significantly reduce disruption to surface infrastructure, traffic, and communities, making them ideal for urban areas.

- Reduced Environmental Impact: Lower vibration levels and less noise compared to blasting, with fewer spoil piles at the surface.

- Consistent Tunnel Shape: TBMs produce a smooth, circular tunnel bore, which often reduces the amount of secondary lining required.

- Automation: Many TBM functions are automated, leading to consistent performance and reduced manual labor.

Notable TBM Projects

TBMs have been instrumental in constructing some of the world's most impressive infrastructure projects, including:

- Channel Tunnel (Eurotunnel): Connecting the UK and France under the English Channel.

- Gotthard Base Tunnel: The world's longest railway tunnel, running through the Alps in Switzerland.

- Crossrail (Elizabeth Line) in London: A massive underground railway system.

- Second Avenue Subway in New York City: Expanding the subway network.

- Seattle's SR 99 Tunnel (Bertha): A large-diameter highway tunnel.

In conclusion, TBMs are engineering marvels that have transformed the way we build underground. Their efficiency, safety, and ability to handle diverse geological conditions make them indispensable tools for creating the vital hidden arteries of modern society.

English

English  русский

русский  عربى

عربى