In the intricate ballet of modern urban development, the seamless delivery of essential services—water, wastewater, power, and telecommunications—often relies on a hidden network of pipelines and conduits. For decades, the installation of such infrastructure meant disruptive open trenches, bringing traffic to a standstill, impacting businesses, and often incurring significant environmental costs. Enter the micro-tunneling machine (MTM): a marvel of engineering that has quietly revolutionized how we build our subterranean arteries, offering unparalleled precision, minimal surface disturbance, and a safer construction environment.

Beyond the Trench: The Imperative for Trenchless Technology

The escalating challenges of dense urban populations, stringent environmental regulations, and the protection of existing infrastructure have driven the widespread adoption of trenchless technologies. Among these, micro-tunneling stands out for its unique ability to install pipelines with exceptional accuracy over considerable lengths, even in highly variable and challenging ground conditions. Its "no-dig" philosophy is not merely a convenience but often a necessity, allowing critical infrastructure to be placed beneath rivers, railways, major highways, and densely built areas without disrupting the world above.

Engineering Elegance: The Mechanics of an MTM Drive

A micro-tunneling operation is a meticulously choreographed sequence of excavation, spoil removal, and pipe jacking, all managed remotely from a sophisticated control cabin.

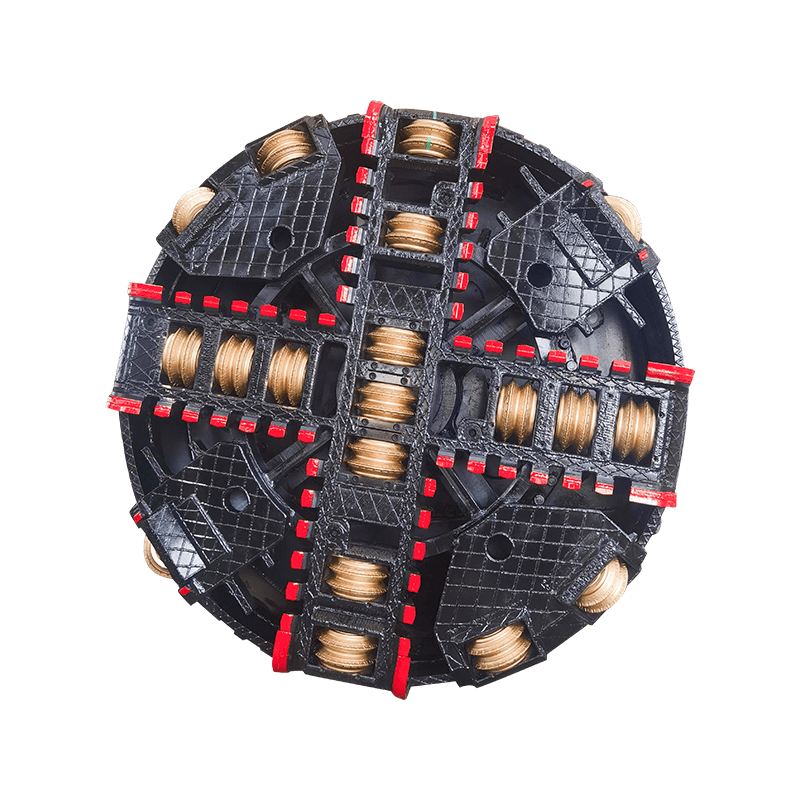

The Cutting Edge: At the forefront is the MTM itself, essentially a miniature tunnel boring machine. Its cutterhead, custom-designed for the specific geological profile (from soft clays to hard rock and mixed faces), rotates to excavate the ground. Unlike traditional TBMs, MTMs are typically "closed-face" machines, meaning the excavation chamber is sealed and pressurized. This pressure, often maintained by a bentonite-based slurry or an earth-pressure balance (EPB) system, directly supports the tunnel face, preventing ground collapse and mitigating settlement at the surface—a critical feature when tunneling beneath existing buildings or sensitive utilities.

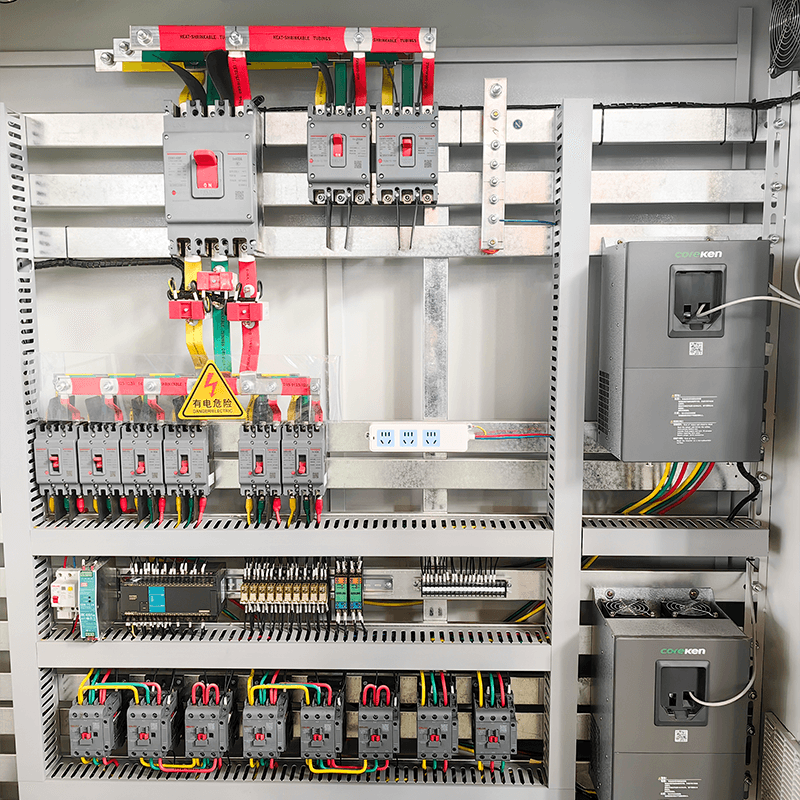

Remote Control and Precision Guidance: The brain of the operation resides in the control cabin, often located safely on the surface. Operators monitor a wealth of real-time data: cutterhead torque, thrust pressure, slurry flow rates, and most critically, the machine's precise position. An advanced laser guidance system, where a target on the MTM is constantly tracked by a total station in the launch shaft, ensures that the machine deviates by mere millimeters from its planned line and grade. Minor corrections are made via articulated steering cylinders on the MTM, allowing for dynamic adjustments as it navigates the subsurface.

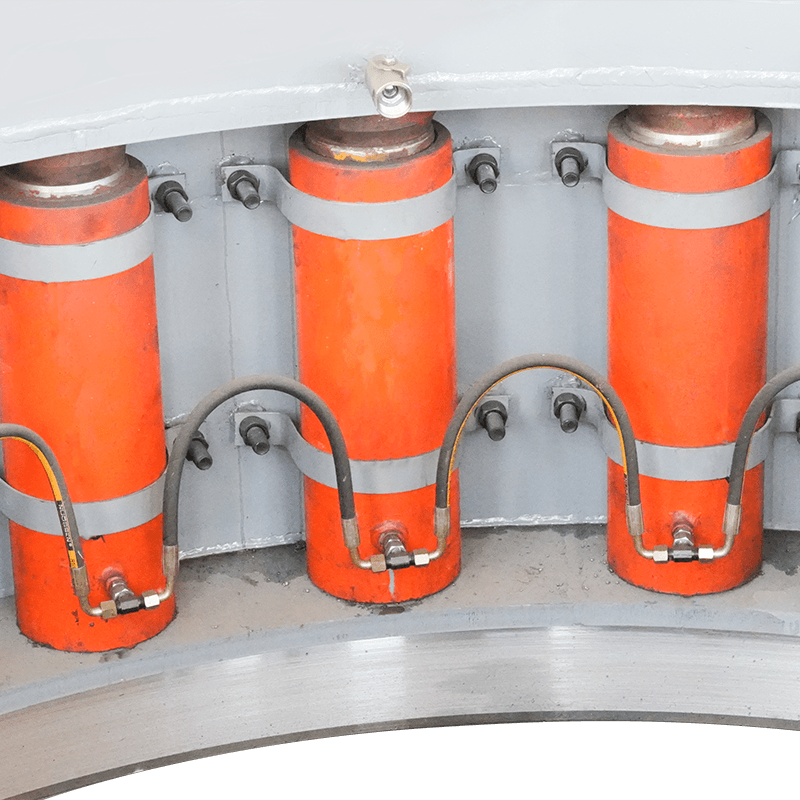

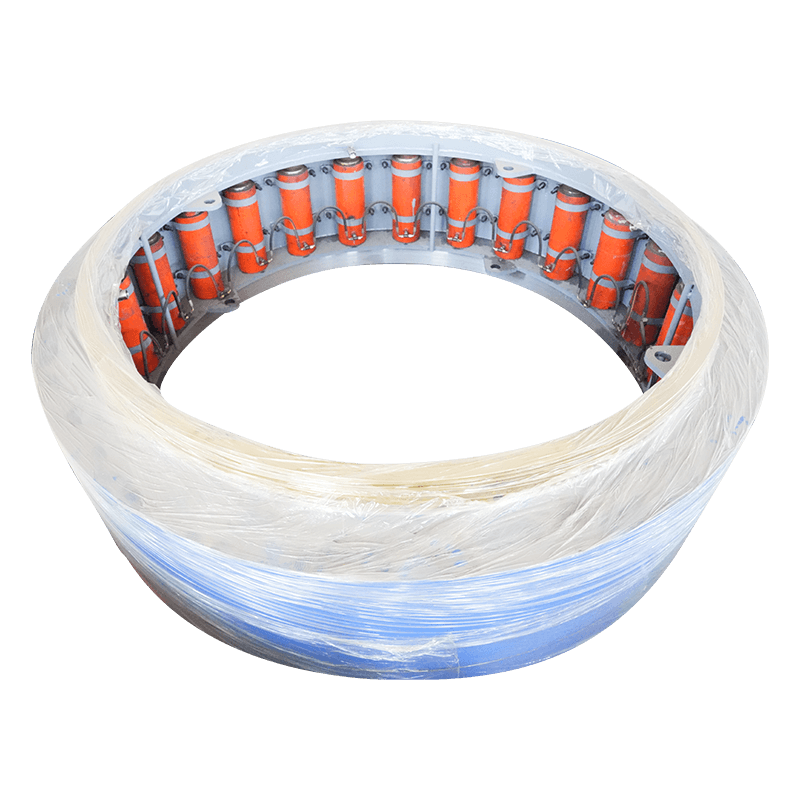

The Jacking Cycle: As the MTM advances, pre-fabricated jacking pipes are pushed behind it from the launch shaft by powerful hydraulic jacks. These pipes, typically made of reinforced concrete, but sometimes steel or GRP, are designed to withstand immense compressive forces. For longer drives, intermediate jacking stations (IJS) can be integrated into the pipe string. These mini-jacking frames react against the already installed pipeline, distributing the overall jacking force and preventing overstressing of individual pipes, thus enabling drives of several hundred meters.

Spoil Management and Slurry Systems: The excavated material, or spoil, is continuously removed. In slurry-based systems, it's mixed with the drilling fluid and pumped back to a surface separation plant, where solids are removed, and the reconditioned slurry is returned to the machine. For less cohesive soils, auger-based systems transport the spoil back via a screw conveyor within the pipe string. The efficiency of spoil management is paramount to maintaining stable face pressure and smooth progress.

Strategic Planning and Geotechnical Imperatives

The success of a micro-tunneling project hinges heavily on meticulous planning and comprehensive geotechnical investigation. Unlike open-cut methods where unforeseen ground conditions can be visibly addressed, the hidden nature of micro-tunneling amplifies the risks of encountering cobbles, boulders, groundwater inflows, or unmapped obstructions. Detailed boreholes, geophysical surveys, and a thorough understanding of soil mechanics are not just recommended, but essential to:

Machine Selection: Matching the cutterhead and excavation system to the predicted geology.

Risk Mitigation: Identifying potential challenges and developing contingency plans.

Lubrication Strategy: Planning the injection of bentonite or polymer lubricants into the annular space between the pipes and the ground to reduce friction and optimize jacking forces.

Shaft Design: Ensuring launch and reception shafts are structurally sound and appropriately sized for equipment and pipe handling.

The Broader Impact: Sustainability and Resilience

Beyond its technical prowess, micro-tunneling contributes significantly to sustainable urban development. By eliminating the need for extensive trenching, it drastically reduces:

Carbon Footprint: Less earthmoving, fewer truck movements for spoil removal, and reduced traffic congestion all contribute to lower emissions.

Environmental Damage: Preserving trees, natural habitats, and minimizing disruption to groundwater tables.

Community Disruption: Less noise, dust, and visual blight, leading to happier residents and businesses.

Furthermore, the precision and depth achievable with MTMs enhance the resilience of critical infrastructure, placing pipelines securely below potential future surface disturbances and ensuring long-term operational integrity.

The Future of Subterranean Construction

The trajectory of micro-tunneling technology points towards even greater automation, leveraging AI and machine learning for predictive maintenance, real-time data analysis, and optimized operational parameters. Remote control capabilities will expand, potentially allowing a single control center to manage multiple simultaneous drives. As our cities become denser and the demand for efficient, sustainable infrastructure grows, micro-tunneling machines will continue to play an increasingly vital, albeit unseen, role in building the robust and resilient urban environments of tomorrow. Their elegant blend of mechanical power, hydraulic precision, and digital intelligence makes them true unsung heroes of modern civil engineering.

English

English  русский

русский  عربى

عربى