In the intricate world of modern construction, where urban landscapes are a puzzle of existing infrastructure, the rock pipe jacking machine stands as a testament to human ingenuity. This specialized piece of equipment is not just a tool; it's a solution, designed to tackle the most formidable geological challenges without disrupting the world above. Also known as a pipe jacking TBM (Tunnel Boring Machine) or a rock micro-TBM, this machine is the hero of underground projects, silently laying the groundwork for our cities' essential networks.

What Makes It a Game Changer?

Imagine trying to build a new sewer line under a busy highway, a river, or a historic building. Traditional methods would require massive, disruptive excavation—a process that is often expensive, time-consuming, and environmentally damaging. This is where the rock pipe jacking machine shines. It operates on a principle of "trenchless" technology, boring a precise tunnel and simultaneously pushing pipes into place behind it.

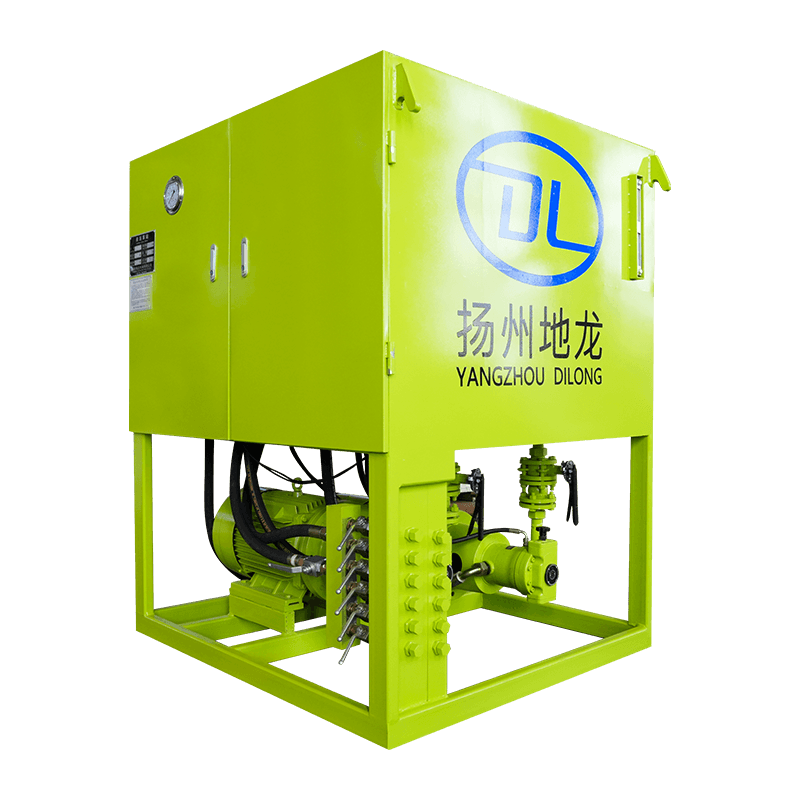

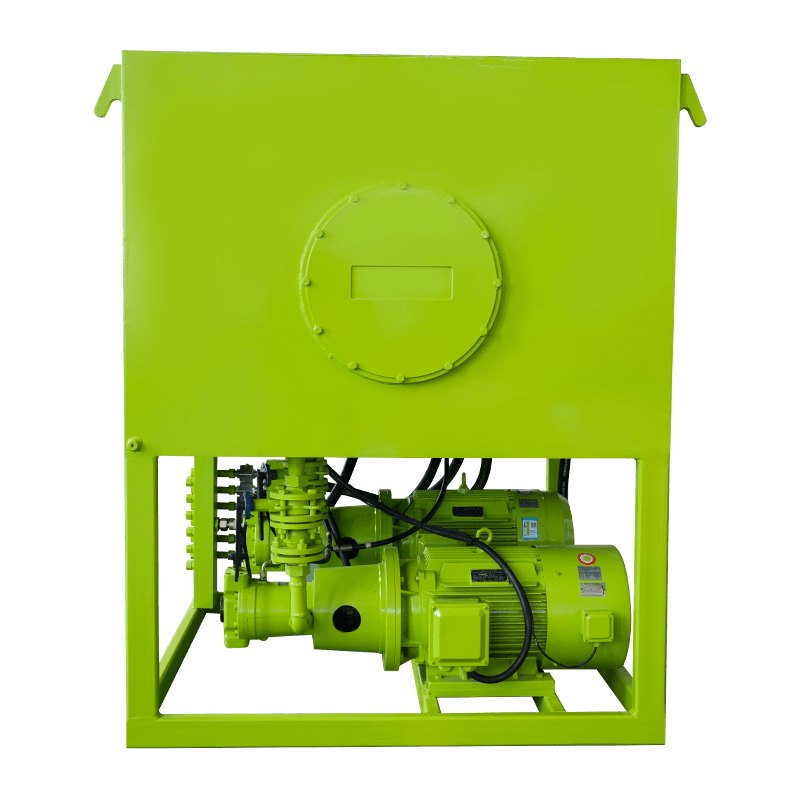

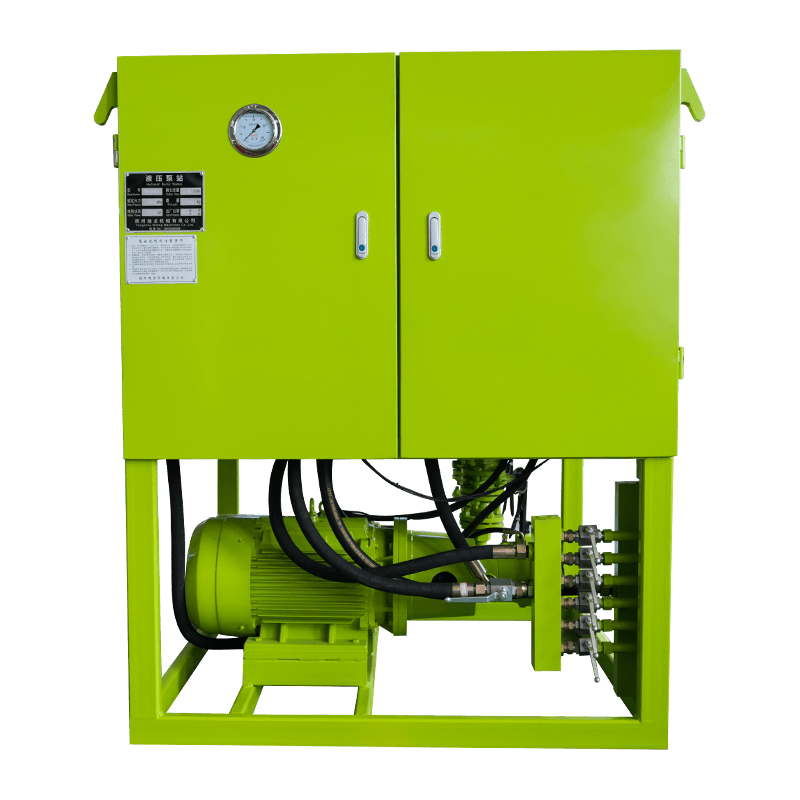

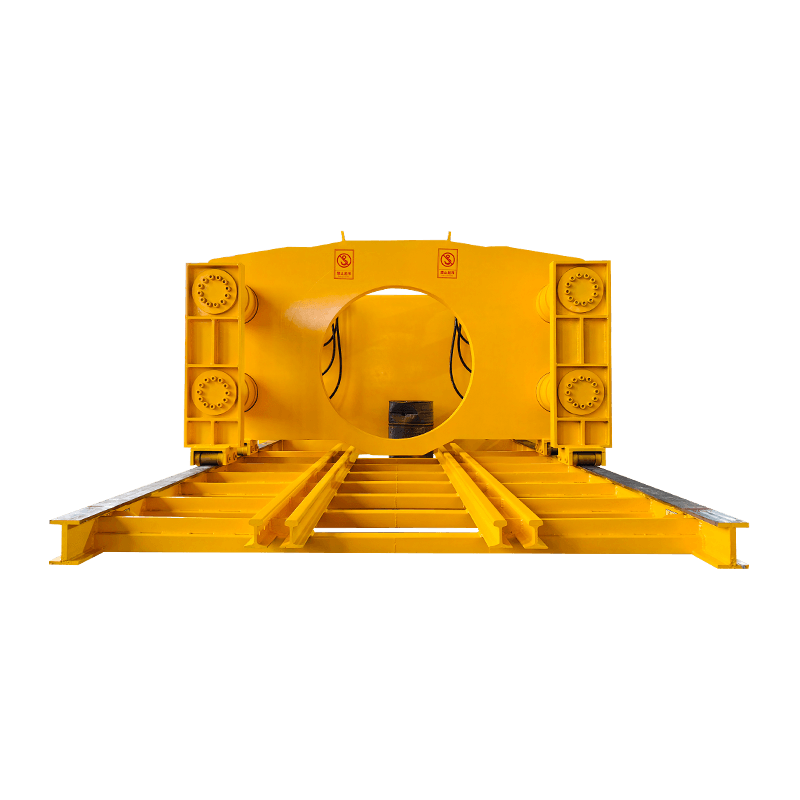

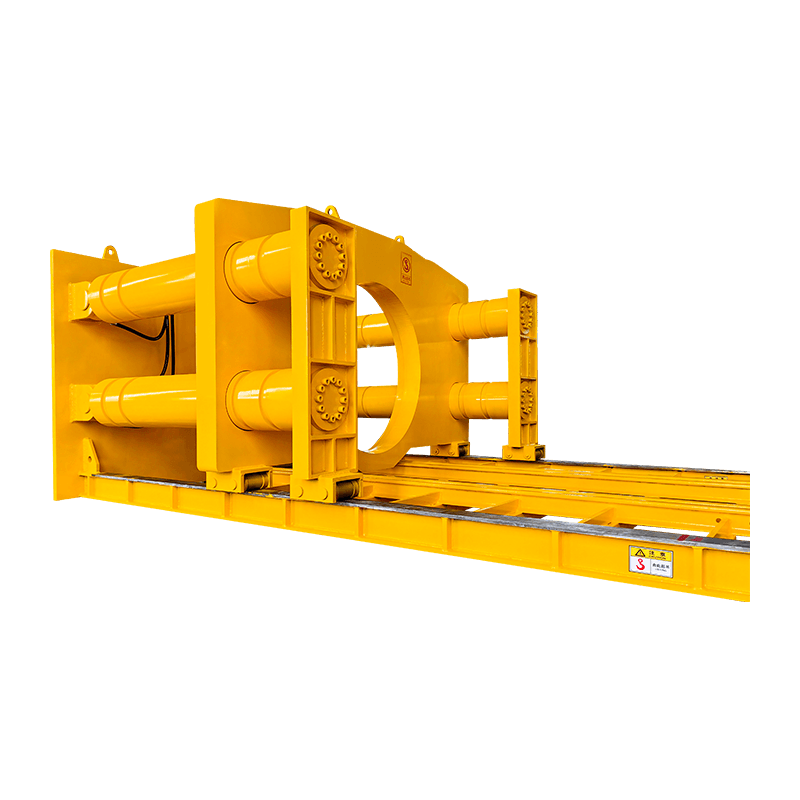

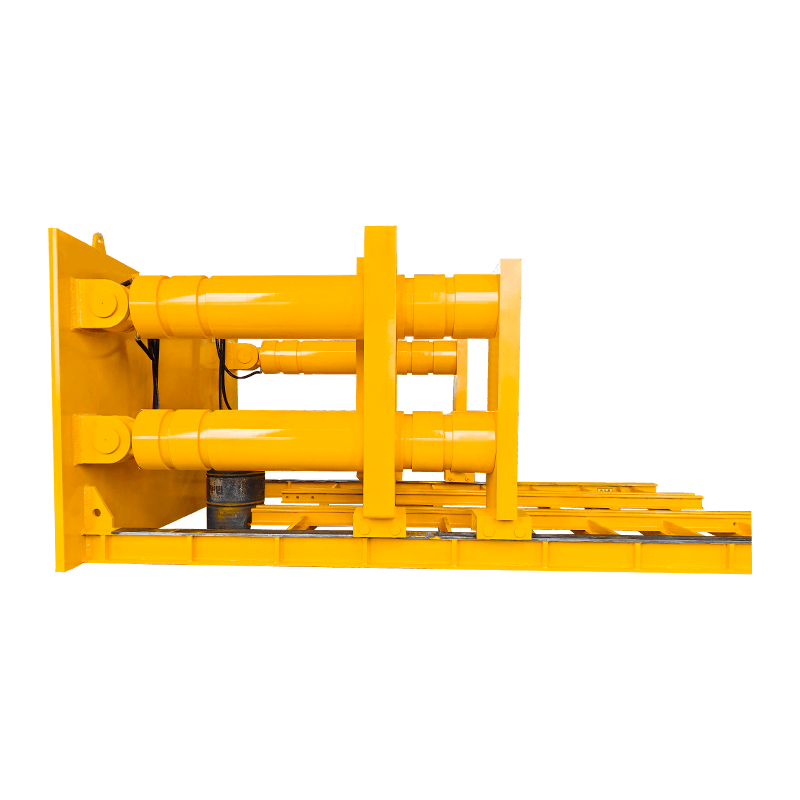

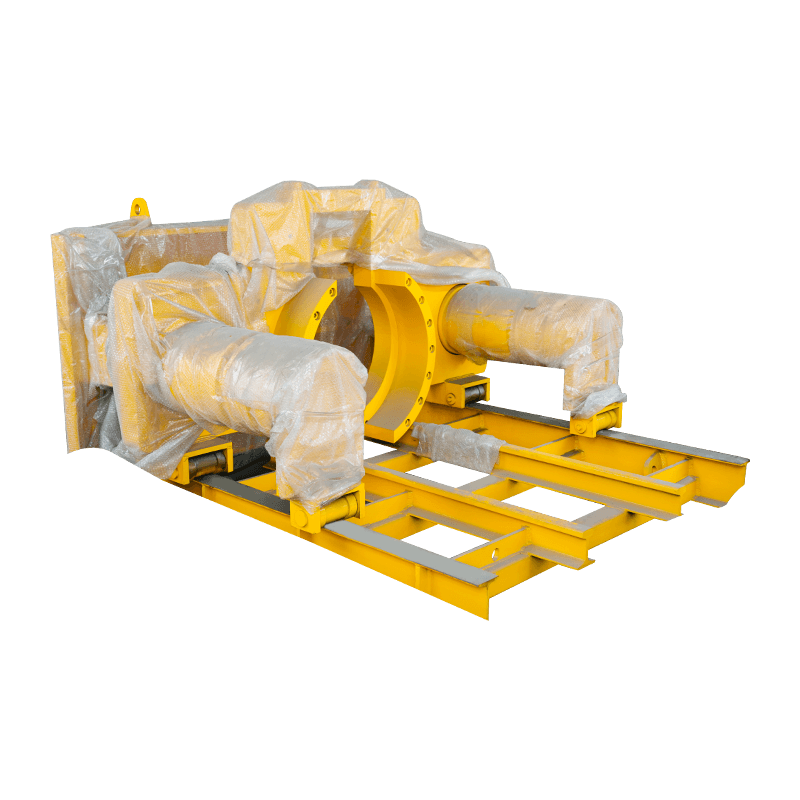

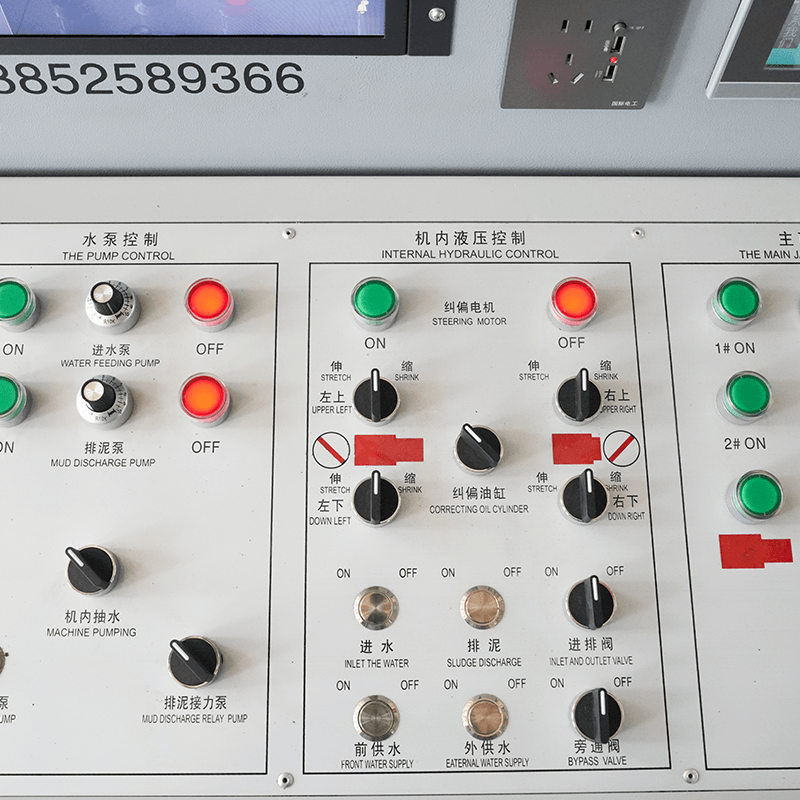

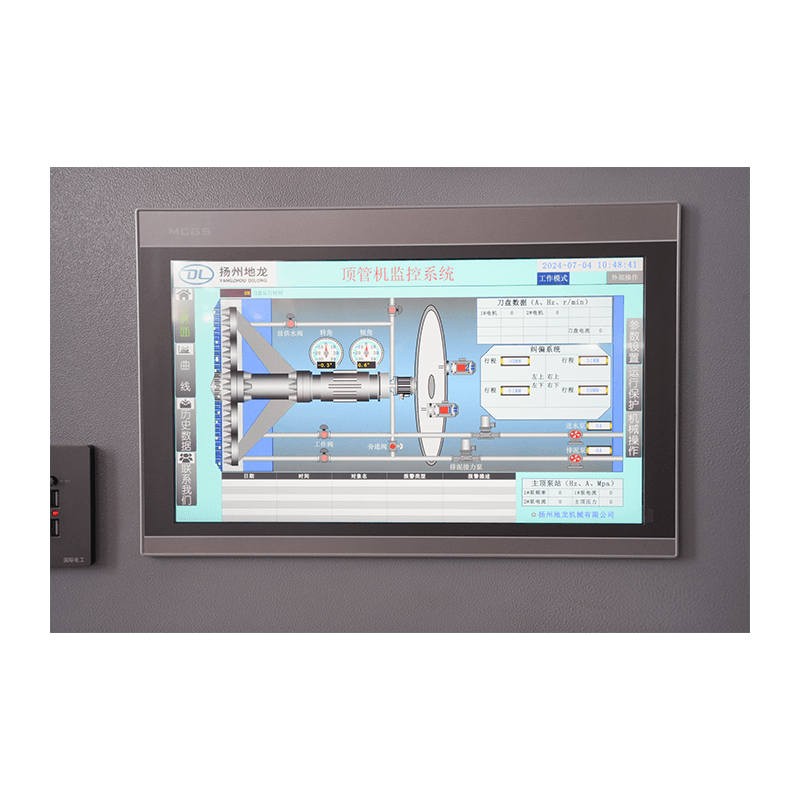

The machine's front, the cutting head, is a marvel of engineering. It's armed with robust disc cutters and carbide bits, specifically designed to grind through solid rock, boulders, and other hard materials that would stop conventional machines in their tracks. As the cutting head breaks through the earth, a powerful hydraulic jacking system at the rear pushes against the pre-fabricated pipe sections, propelling the entire machine forward. This process creates a continuous, stable tunnel, ensuring the pipeline is secure from the moment it is laid.

The Advantages Are More Than Just Underground

The benefits of using a rock pipe jacking machine extend far beyond its ability to handle tough ground conditions. The key advantages include:

-

Minimal Surface Disturbance: This technology is ideal for high-density urban areas, eliminating the need for extensive open-cut trenches and the associated traffic disruptions and noise pollution.

-

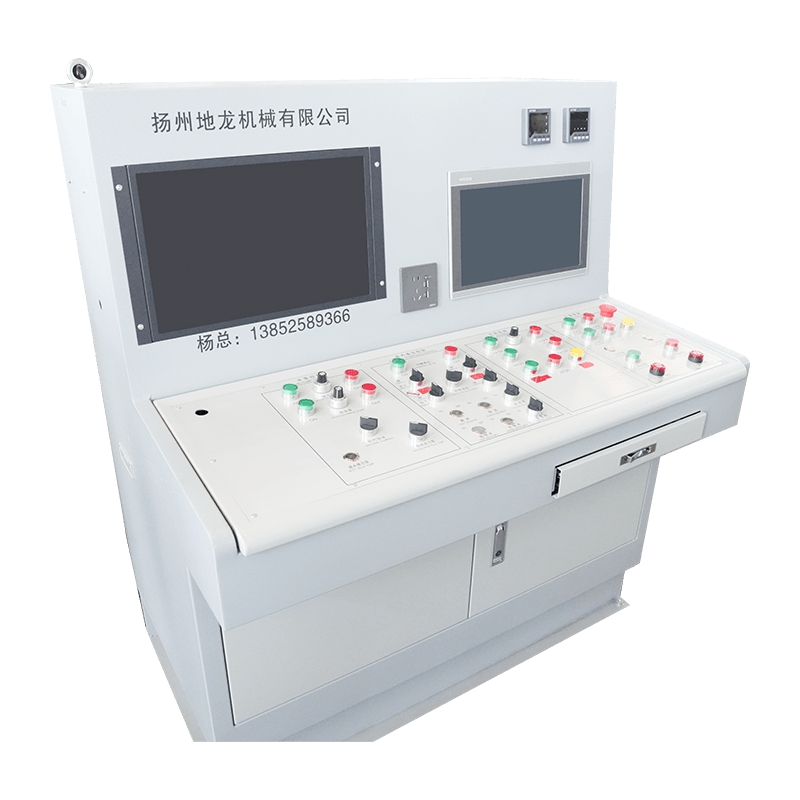

Exceptional Precision: Guided by advanced laser systems, the machine can maintain a highly accurate alignment and grade, which is critical for gravity-fed systems like sewers and storm drains.

-

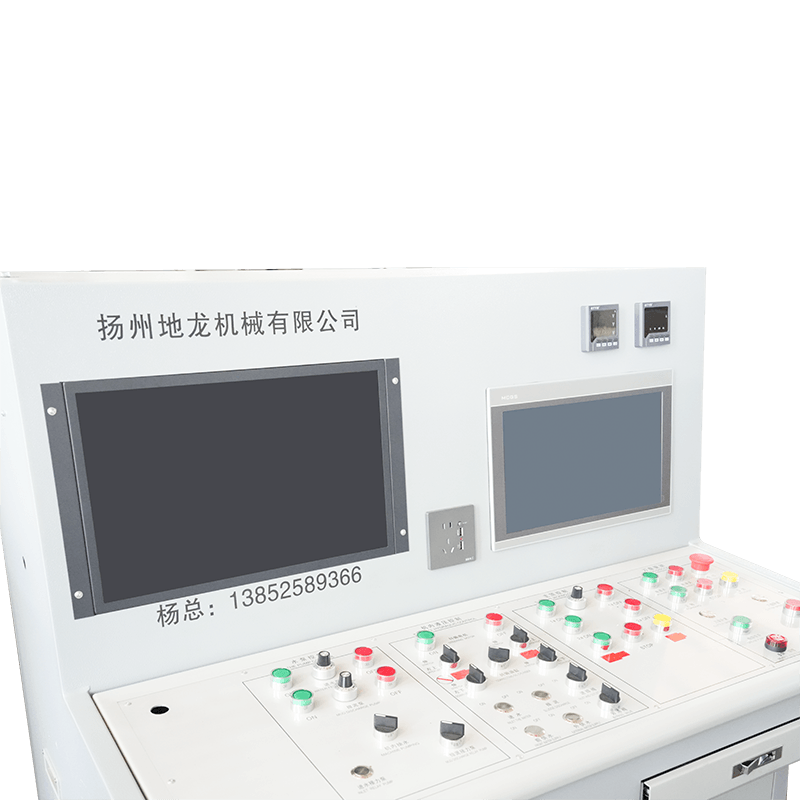

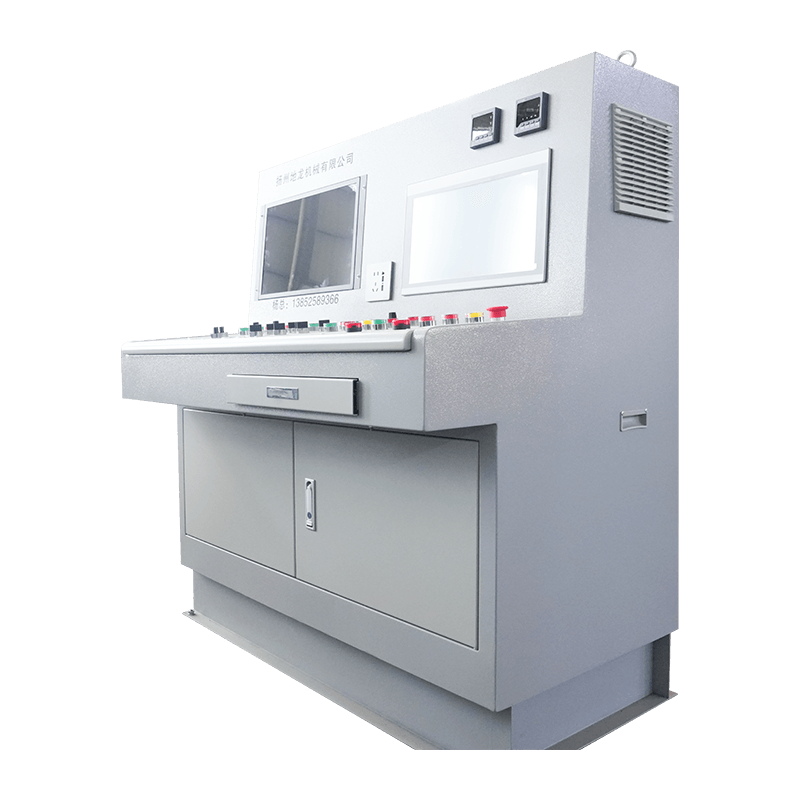

Enhanced Safety: The process is largely automated, which reduces the need for workers to be at the tunnel face, significantly minimizing safety risks.

-

Structural Integrity: The immediate installation of the pipe as the tunnel is bored provides instant ground support, preventing collapse and ensuring the long-term stability of the structure.

A Vital Tool for Our Future

The applications for a rock micro-TBM are vast and crucial. From installing large-diameter sewer and stormwater pipes to creating utility tunnels for electricity and telecommunications, and even serving as a pilot tunnel for larger subway projects, this machine is a fundamental component of modern infrastructure development.

As our cities continue to expand and the need for new, resilient infrastructure grows, the pipe jacking TBM will remain a vital tool. It represents a smarter, safer, and more sustainable way to build, allowing us to connect and grow without tearing our world apart. It is a powerful reminder that sometimes, the most important work is done right under our feet, unseen but essential.

English

English  русский

русский  عربى

عربى