In the world of modern construction, where urban landscapes are becoming increasingly dense and infrastructure projects need to minimize disruption, the pipe jacking machine has emerged as a revolutionary tool. This sophisticated piece of equipment, often referred to as a microtunneling machine or pipe ramming machine, is the workhorse of a trenchless construction method that installs underground pipelines with surgical precision. Unlike traditional cut-and-cover methods that involve extensive excavation and can cause significant disruption to traffic and daily life, pipe jacking allows for the installation of pipes, culverts, and utility conduits with minimal surface disturbance.

How It Works: A Subterranean Journey

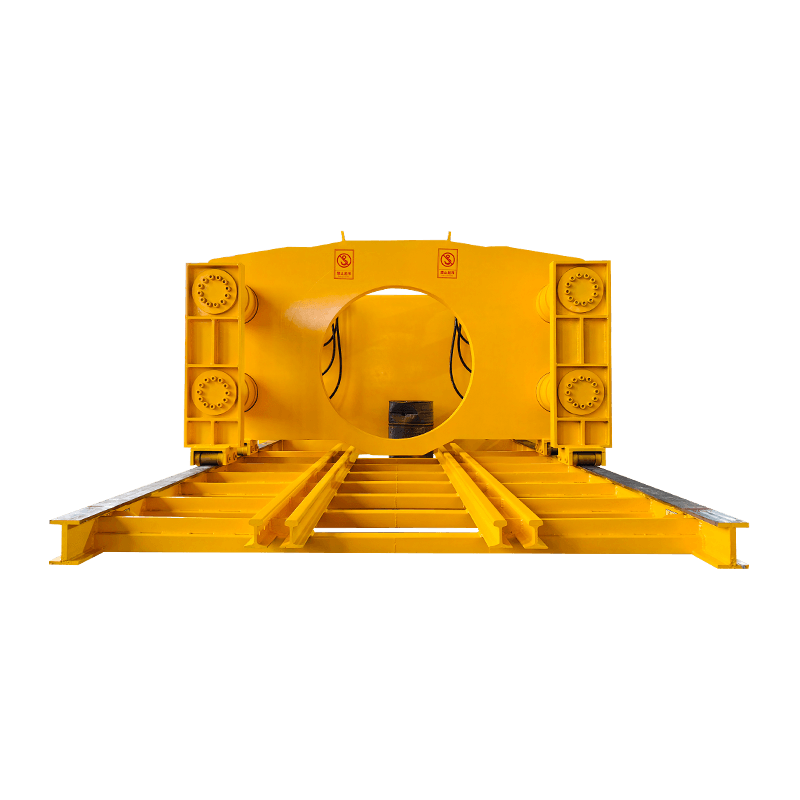

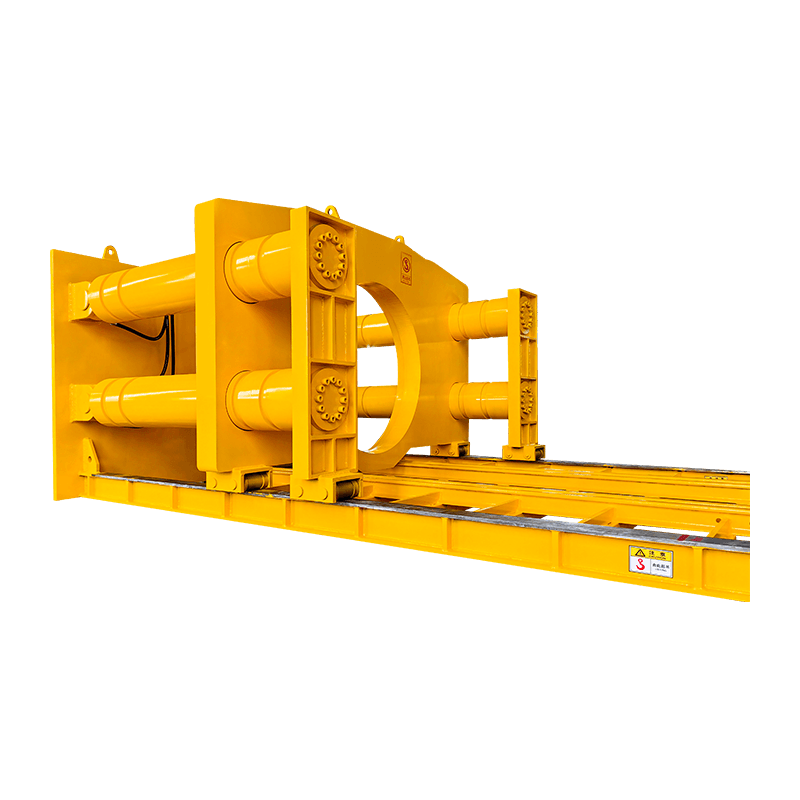

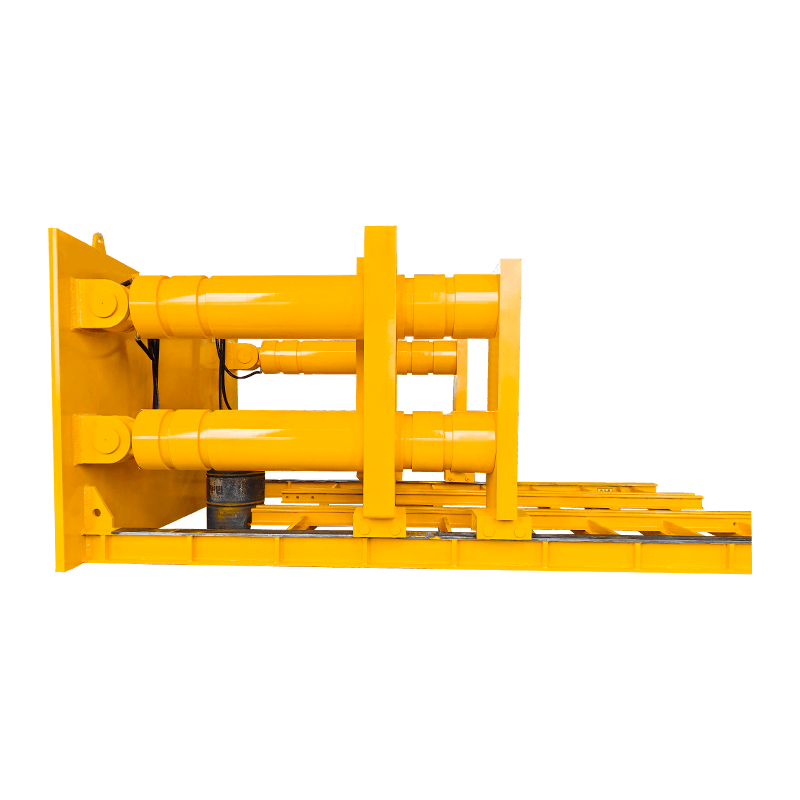

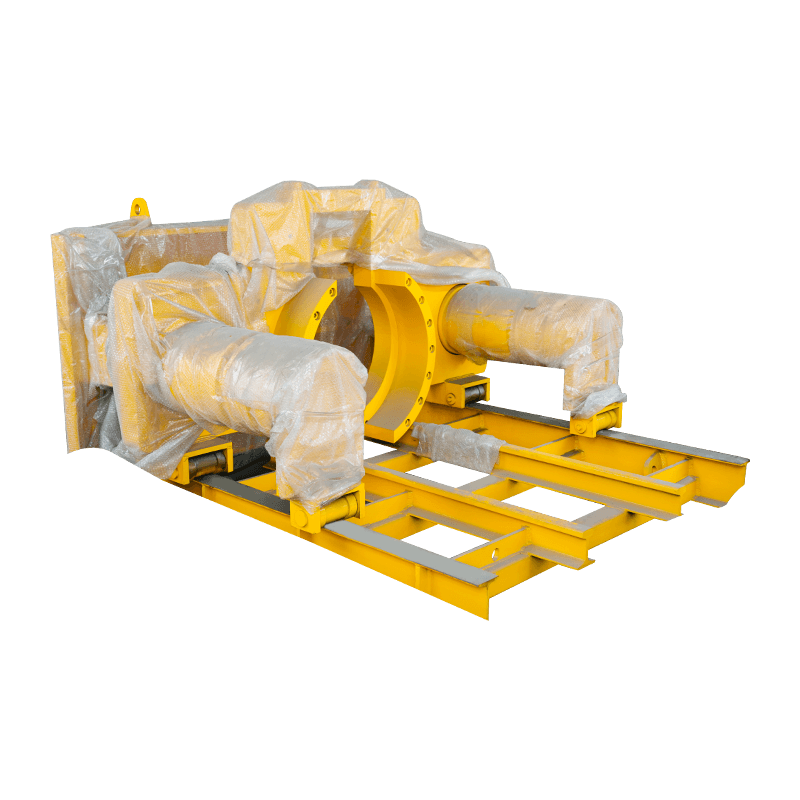

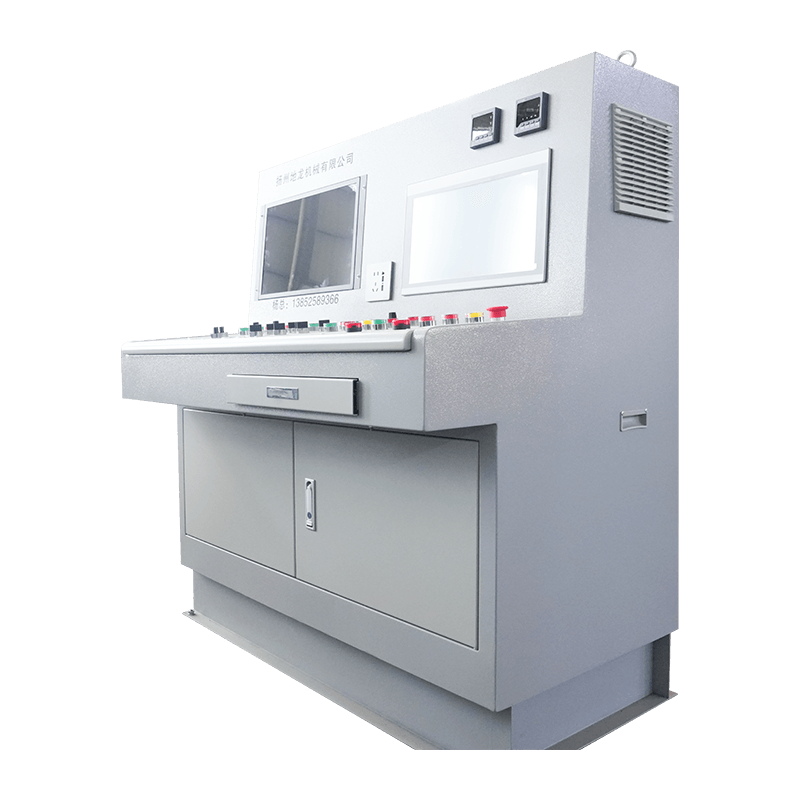

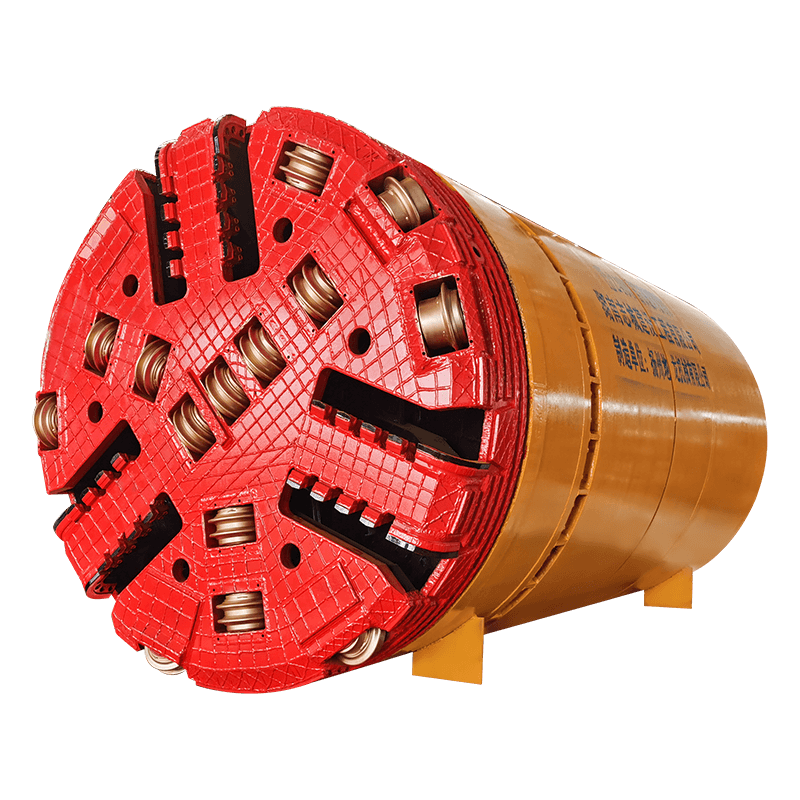

The process begins with the excavation of two shafts: a "launch shaft" where the machine and pipes are introduced, and a "reception shaft" where the machine eventually emerges. The pipe jacking machine, which consists of a cutting head, a steerable shield, and a jacking system, is lowered into the launch shaft.

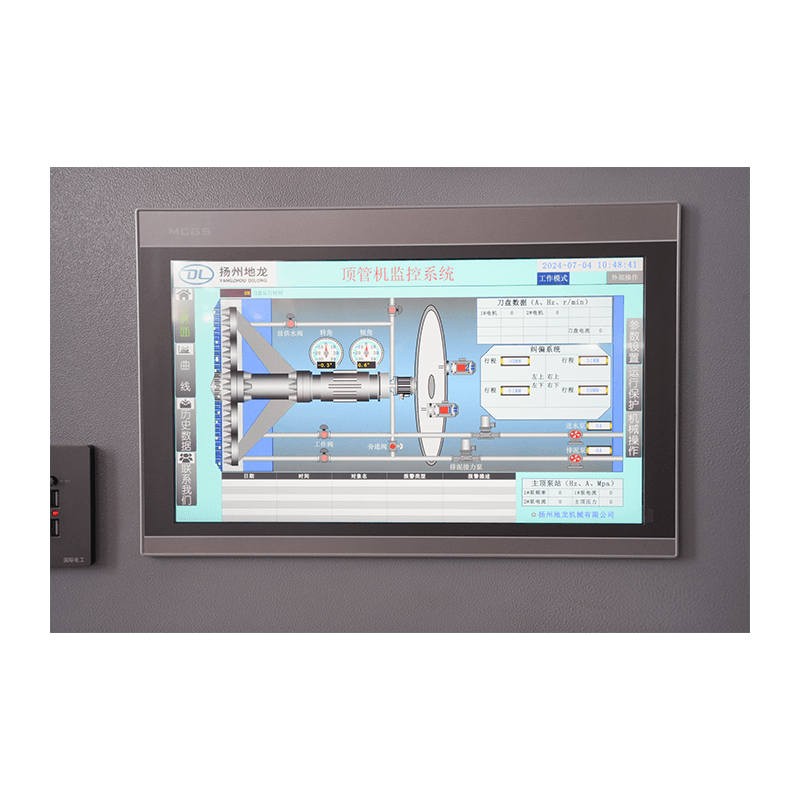

The machine's cutting head is engineered to handle a wide range of geological conditions, from soft clay and sand to hard rock. As it rotates and bores through the ground, powerful hydraulic jacks located in the launch shaft push the first section of prefabricated pipe directly behind the cutting head. This is the core of the "jacking" process. As the machine advances and the first pipe section enters the ground, a new pipe is lowered into the launch shaft and connected, and the process is repeated. The excavated soil is simultaneously removed from the cutting face, typically via a conveyor or slurry system, and brought back to the launch shaft for disposal.

Key Features and Components

Modern pipe jacking machines are packed with advanced technology to ensure accuracy and efficiency.

-

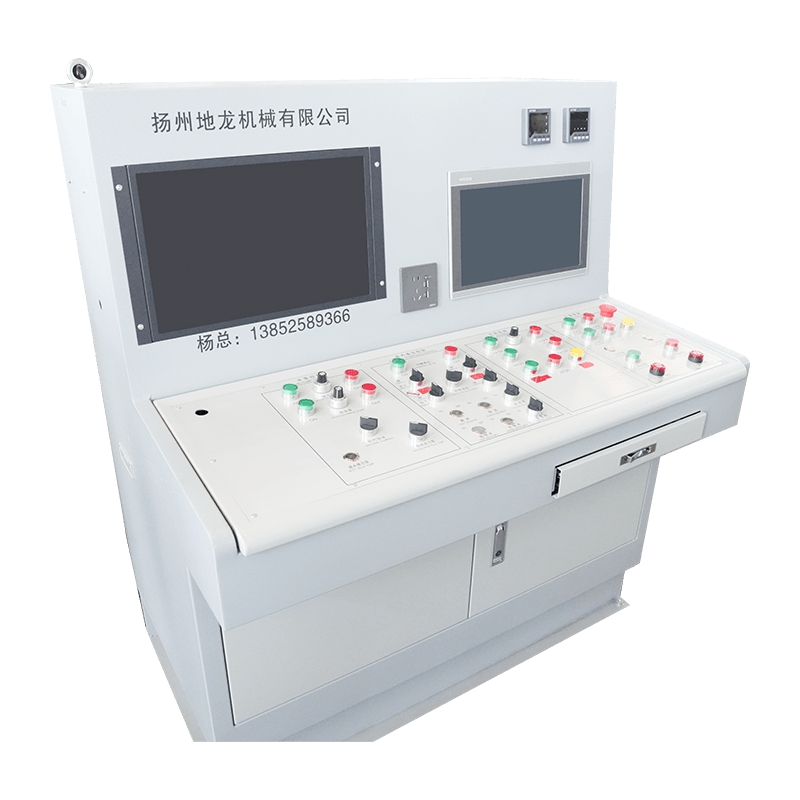

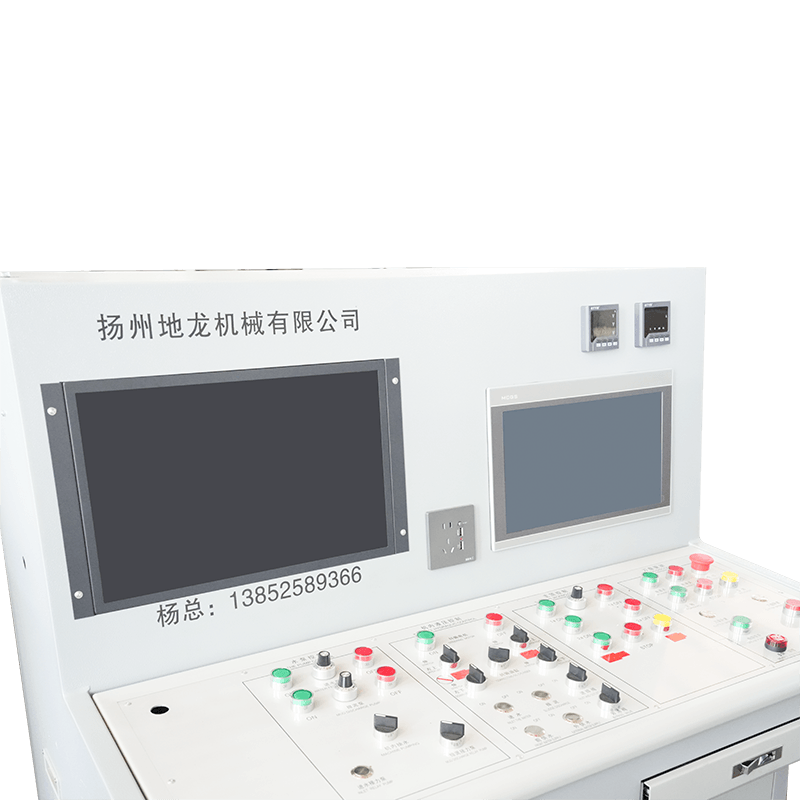

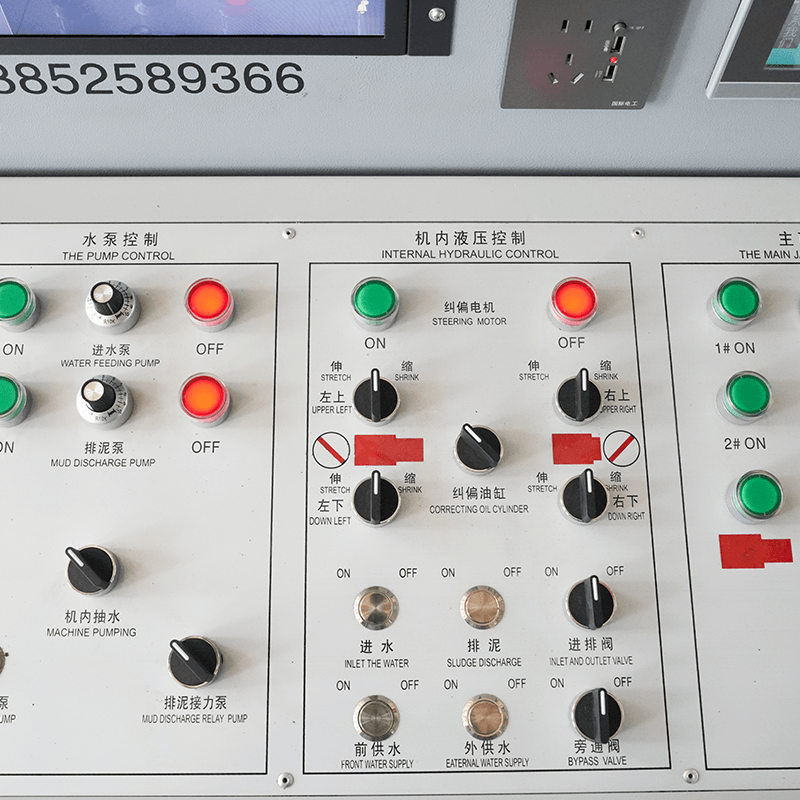

Guidance Systems: To maintain the correct line and grade, these machines rely on sophisticated guidance systems, often involving a laser transit set up in the launch shaft. The machine’s operator receives real-time data on the machine's position and orientation, allowing for precise steering corrections. This level of control is what makes the technology suitable for navigating under sensitive structures like railways, rivers, and existing buildings.

-

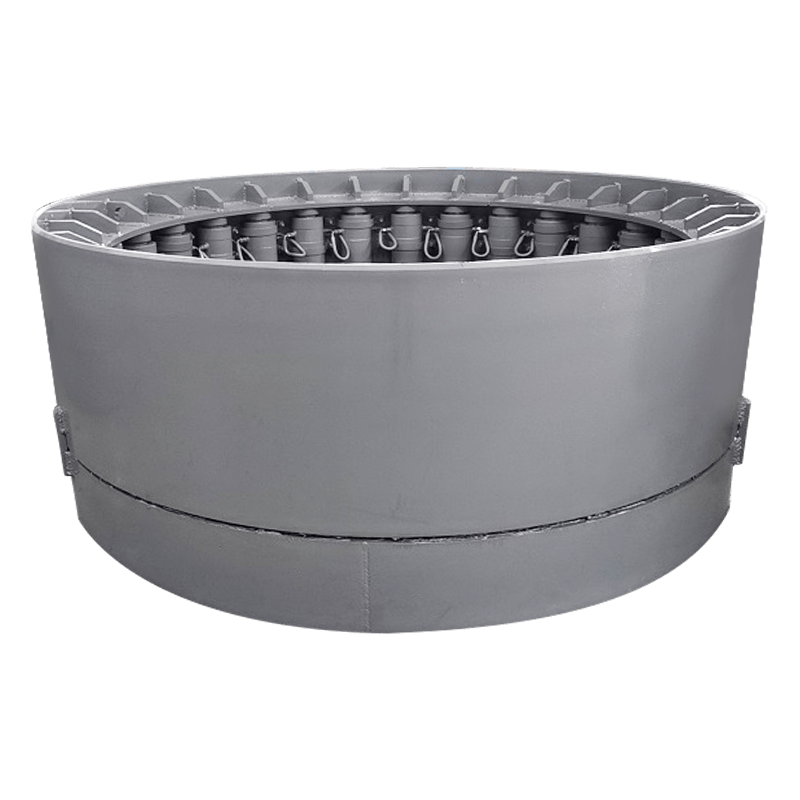

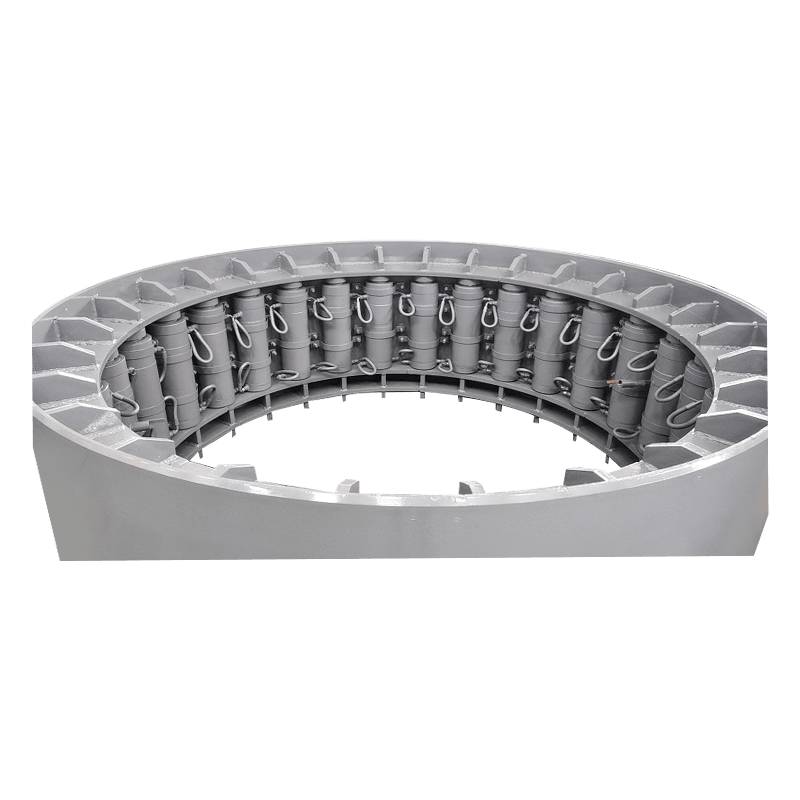

Adaptable Cutter Heads: The ability to change out cutter heads is a crucial feature. Different heads are designed for various ground conditions, from open-face heads for stable soils to closed-face, Earth Pressure Balance (EPB) or slurry-based systems for unstable, water-saturated ground. This versatility means a single machine can be used on diverse projects.

-

Modular Design: The modular nature of the equipment allows it to be configured for a wide range of pipe diameters and lengths, providing a flexible solution for different project requirements, from small utility lines to large pedestrian subways.

-

High-Thrust Capability: The hydraulic jacking systems are engineered to generate immense thrust, overcoming the frictional resistance between the pipes and the surrounding soil over long distances.

Applications and Advantages

The pipe jacking machine is a go-to solution for a broad spectrum of civil engineering projects. Its applications include:

-

Installing new sewer, drainage, and water pipelines.

-

Laying telecommunication and power cables.

-

Creating underpasses for roads and railways.

-

Building culverts and drainage systems.

The advantages of this method are clear. It drastically reduces surface disruption, minimizes noise and traffic congestion, and is often more cost-effective and faster than open-trench methods, particularly in urban or environmentally sensitive areas. Its ability to install a finished, watertight, and structurally sound pipeline as it advances offers a significant benefit, ensuring long-term durability and efficiency.

In essence, the pipe jacking machine is more than just a piece of machinery; it's a strategic tool for urban development, allowing for the seamless and efficient expansion of our vital infrastructure without turning our cities upside down. It represents a shift towards smarter, less intrusive construction practices that benefit both project timelines and the communities they serve.

English

English  русский

русский  عربى

عربى