In the world of urban development and infrastructure, the challenges of working underground are immense. From navigating dense utility networks to preserving historical landscapes and minimizing disruption to daily life, traditional open-cut methods are often not a viable option. This is where the Micro-tunneling Machine emerges as a game-changer, a marvel of modern engineering that is revolutionizing how we build subterranean infrastructure. This isn't just a piece of machinery; it's a solution that embodies precision, efficiency, and environmental responsibility, making it an indispensable tool for forward-thinking construction projects.

At its core, the Micro-tunneling Machine is a remote-controlled, trenchless technology used to install pipes and conduits with incredible accuracy. Unlike its larger counterpart, the Tunnel Boring Machine (TBM), which is used for full-scale transportation tunnels, the micro-tunneling machine is designed for smaller-diameter projects, typically ranging from 300 mm to over 3,000 mm. This specialized capability allows it to tackle a wide array of applications, including sewer lines, water mains, gas pipelines, and utility crossings beneath rivers, roads, and railways.

The Anatomy of a Precision Tool

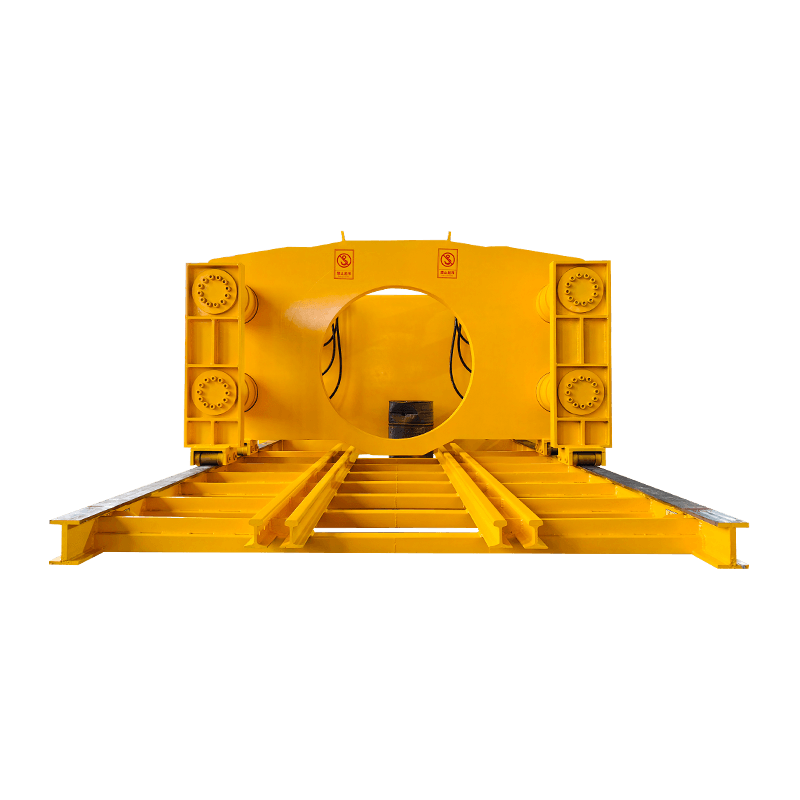

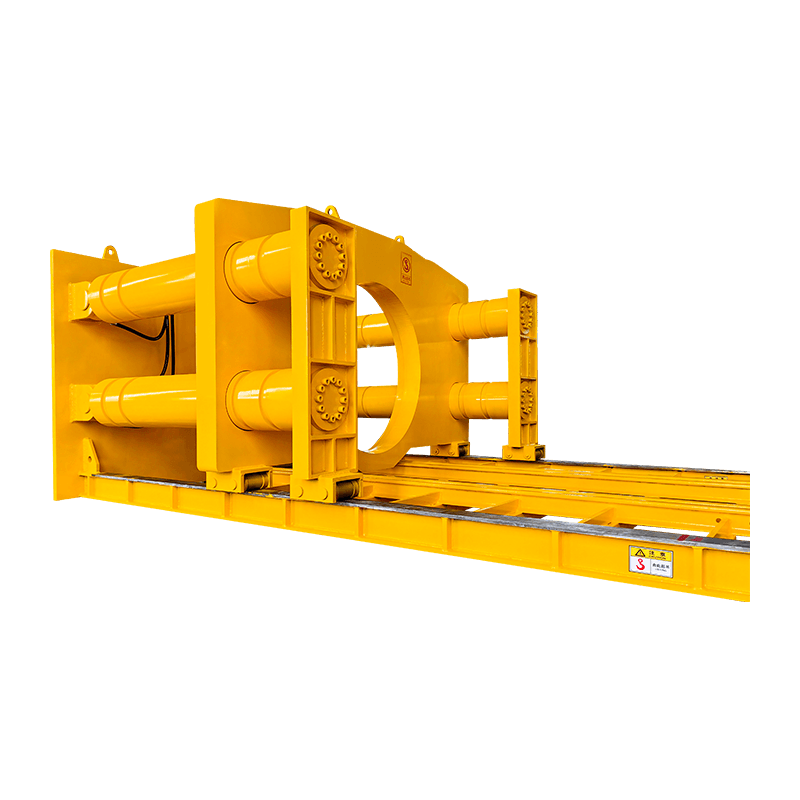

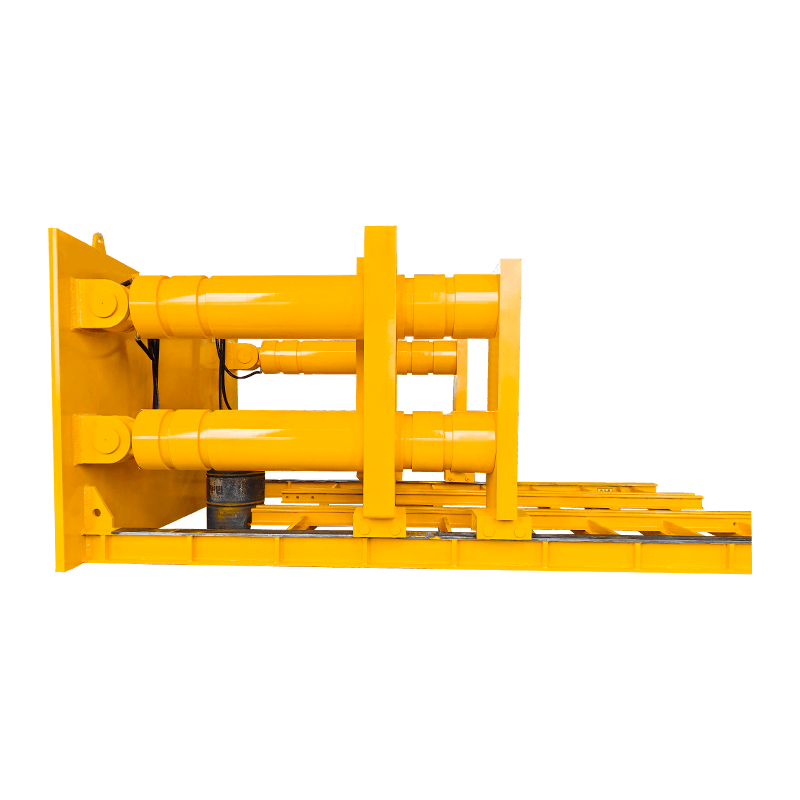

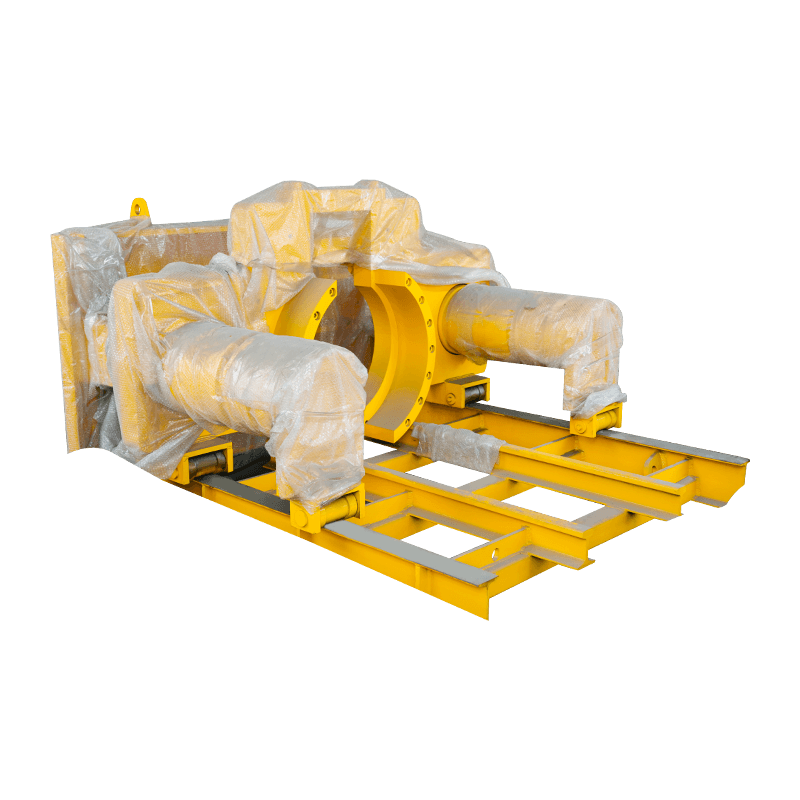

Understanding the power of the Micro-tunneling Machine requires a closer look at its sophisticated components. The machine's head, or shield, is equipped with a cutting wheel or a series of cutting tools designed to excavate the ground in front of it. This head is capable of handling various soil conditions, from soft clay and sand to hard rock, thanks to interchangeable cutting tools.

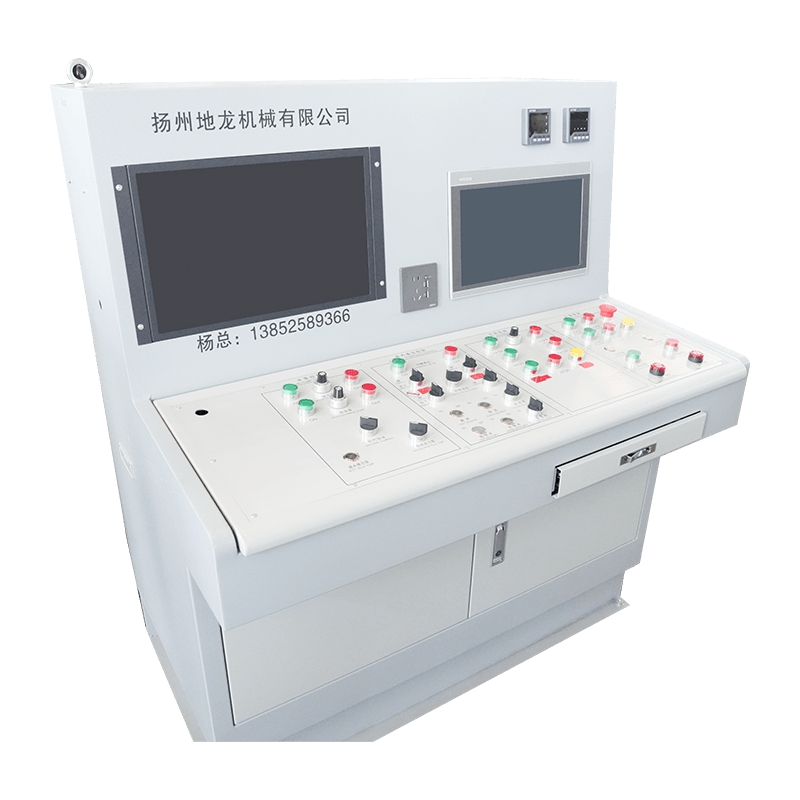

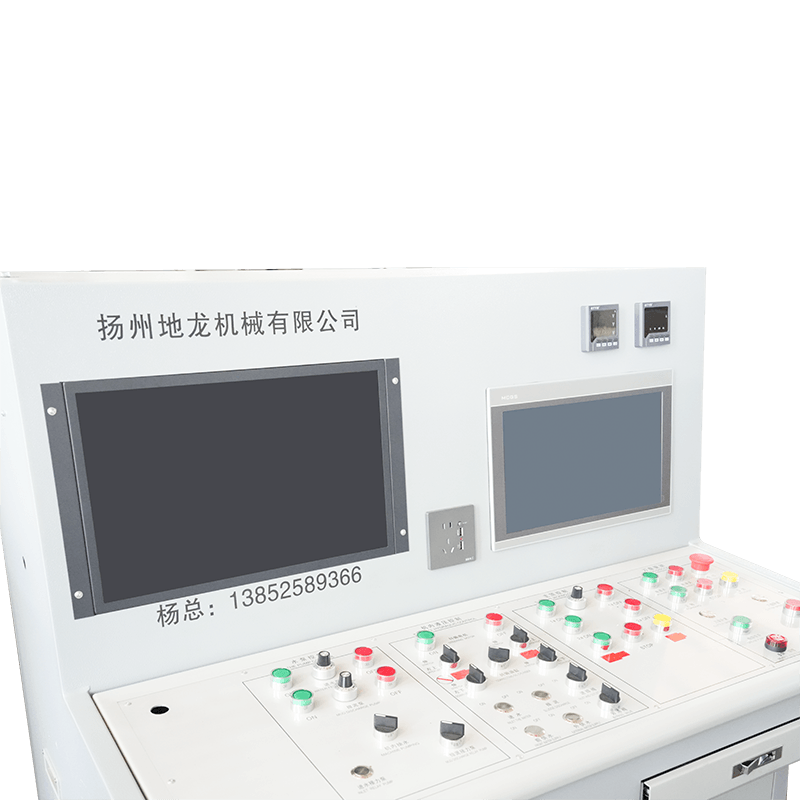

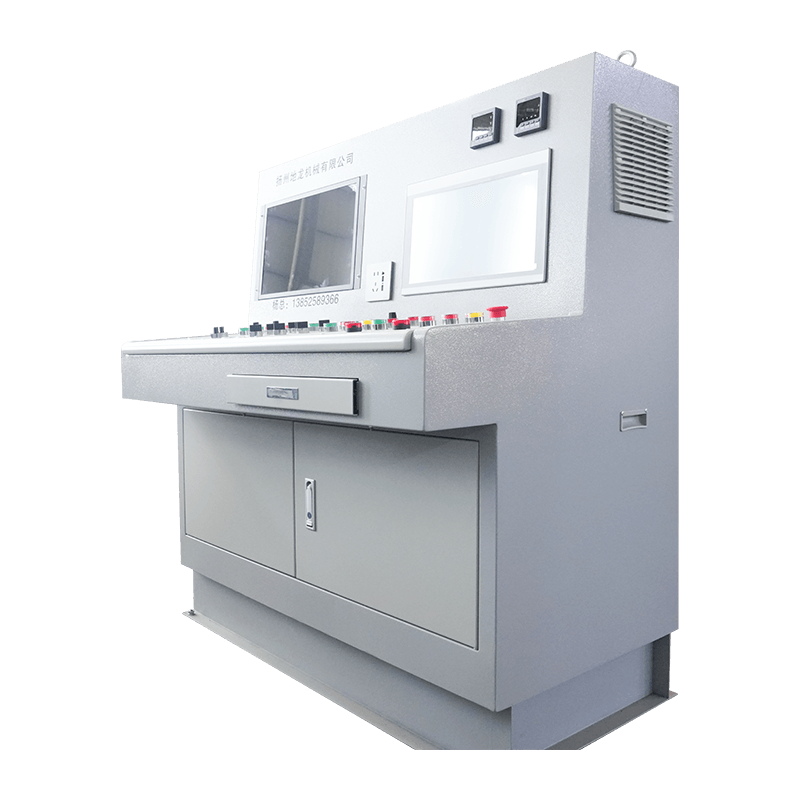

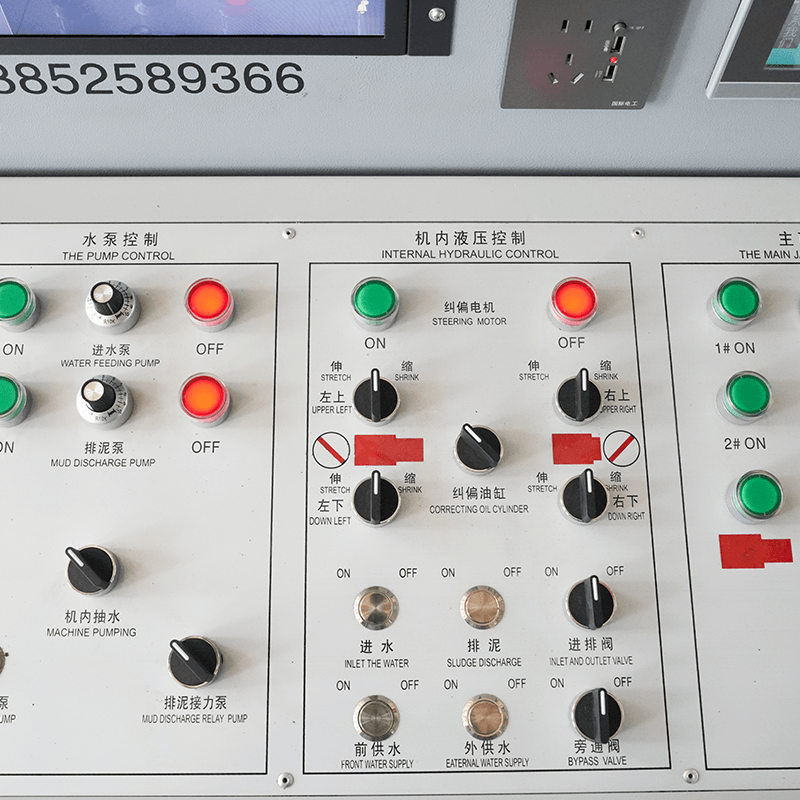

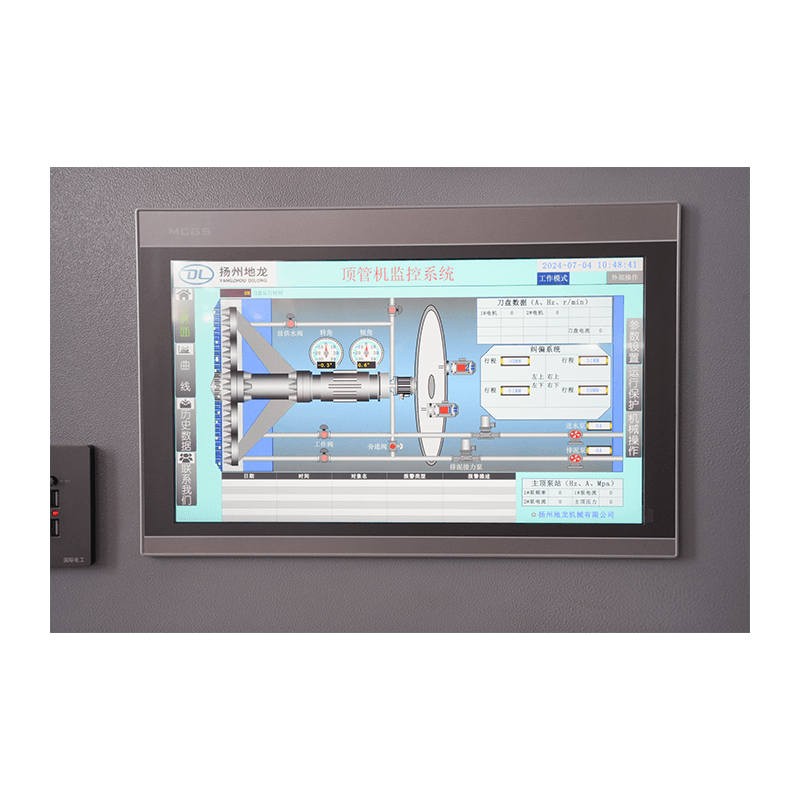

Behind the cutting head lies a powerful jacking system. This system is crucial, as it pushes the pipe string forward from a launch shaft, a key part of the trenchless method. The pipe segments, often made of concrete, steel, or other high-strength materials, are successively pushed into the ground as the excavation progresses. A slurry or muck pump system removes the excavated soil and rock, transporting it to the surface for disposal. The entire operation is monitored and controlled from a control cabin on the surface, allowing operators to make real-time adjustments to steering, jacking pressure, and slurry flow, ensuring the tunnel stays precisely on its planned alignment.

Why Choose a Micro-tunneling Machine? The Core Advantages

The appeal of the Micro-tunneling Machine lies in its numerous advantages over traditional construction methods. The most significant benefit is the minimal surface disruption. By operating entirely underground, this technology eliminates the need for extensive excavation pits, road closures, and the resulting traffic congestion and noise pollution. This is particularly critical in densely populated urban areas or environmentally sensitive locations.

Furthermore, the Micro-tunneling Machine offers unparalleled accuracy and safety. The remote-controlled nature of the operation removes personnel from the hazardous tunnel face, significantly improving worker safety. The machine's guidance systems, which often utilize lasers and gyroscopes, can achieve incredibly tight tolerances, ensuring that the installed pipeline follows the intended path with millimeter-level precision. This accuracy is vital for gravity-fed sewer systems, where proper grade is essential for functionality.

Another key advantage is speed and efficiency. Once the machine is set up and operational, the boring and pipe jacking can proceed at a continuous pace, often much faster than open-cut methods which are subject to weather, traffic, and ground instability issues. This streamlined process reduces overall project timelines and costs. The trenchless nature also means there is less restoration work needed, as the landscape above the tunnel remains largely untouched, saving time and money on landscaping and road repairs.

Applications and the Future of Underground Construction

The versatility of the Micro-tunneling Machine has led to its adoption in a wide range of applications globally. It has been instrumental in modernizing city infrastructure, allowing for the rapid installation of new utility lines without disrupting historic city centers. It is also a staple in major water and sanitation projects, providing a clean and efficient way to build critical pipelines. The machine's ability to bore beneath sensitive ecosystems has also made it a preferred choice for environmental projects.

Looking ahead, the Micro-tunneling Machine will continue to evolve. Advancements in automation, sensor technology, and artificial intelligence will make these machines even smarter, allowing them to adapt to changing ground conditions autonomously. The development of more powerful and compact machines will enable them to take on an even broader range of projects, further cementing their role as a foundational technology in the future of underground construction. The Micro-tunneling Machine is more than a piece of equipment; it represents a commitment to building a more sustainable, efficient, and less disruptive future for our cities and communities.

English

English  русский

русский  عربى

عربى