The foundation of modern subterranean infrastructure—from metro systems and high-speed railways to vital water and utility tunnels—rests on the capabilities of Tunnel Boring Machines (TBMs). The complex, specialized process of TBM Manufacturing is a critical, high-stakes discipline within heavy industry, driving global urban development and resource management.

Anatomy of a 'Mole': Key Components and Customization

TBMs, often nicknamed 'moles,' are not standardized products; they are bespoke engineering marvels, custom-designed to address the unique geological challenges of each project. TBM Manufacturing centers on integrating several critical, precision-engineered components:

-

The Cutterhead: This rotating face of the machine is perhaps the most crucial component. It is equipped with specialized cutting tools—discs, rippers, or scrapers—whose material composition and geometry are meticulously matched to the anticipated rock strength and soil conditions.

-

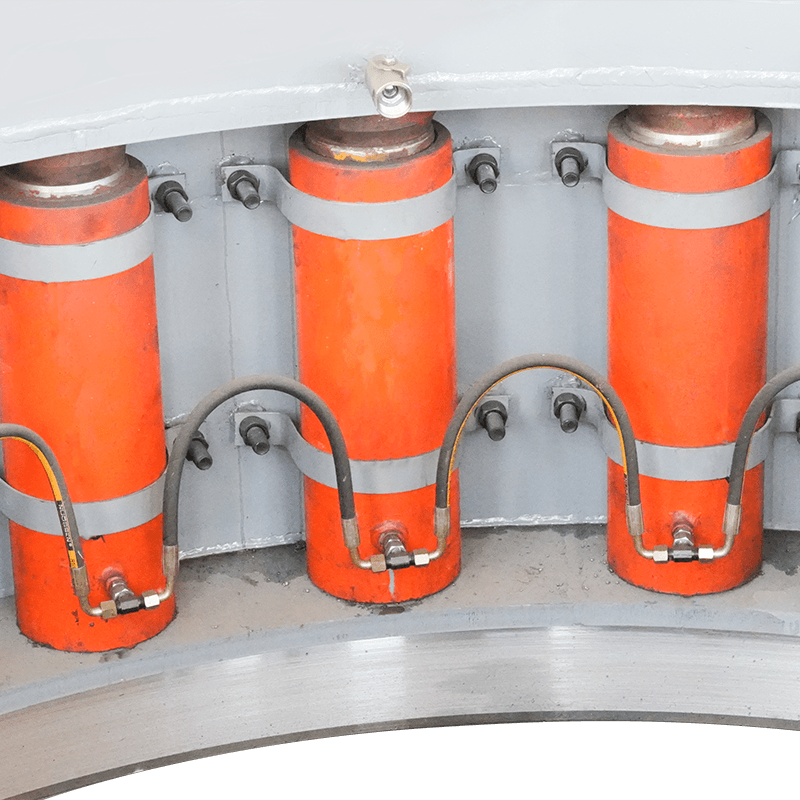

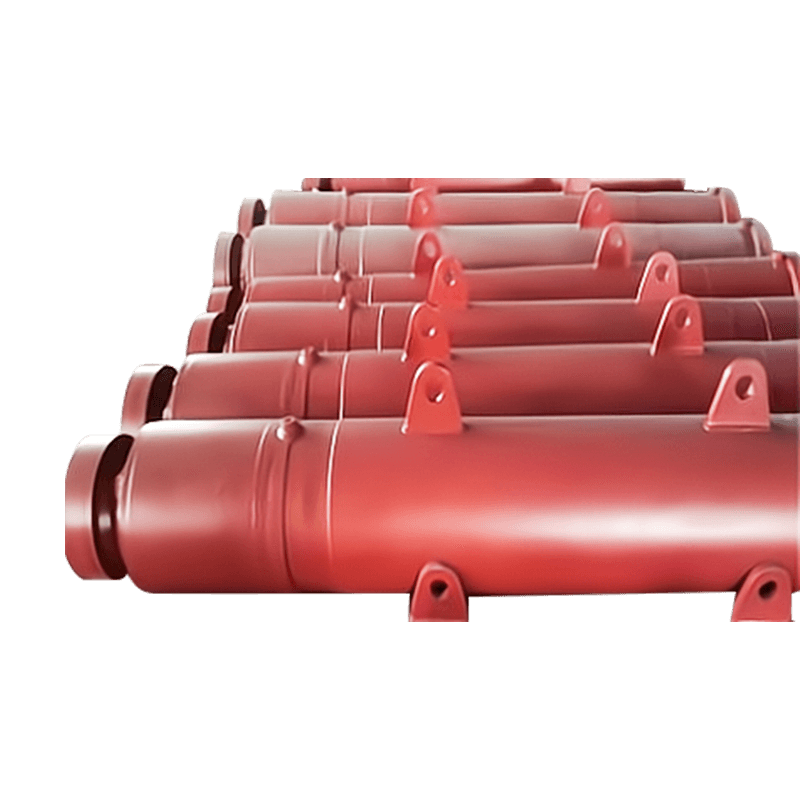

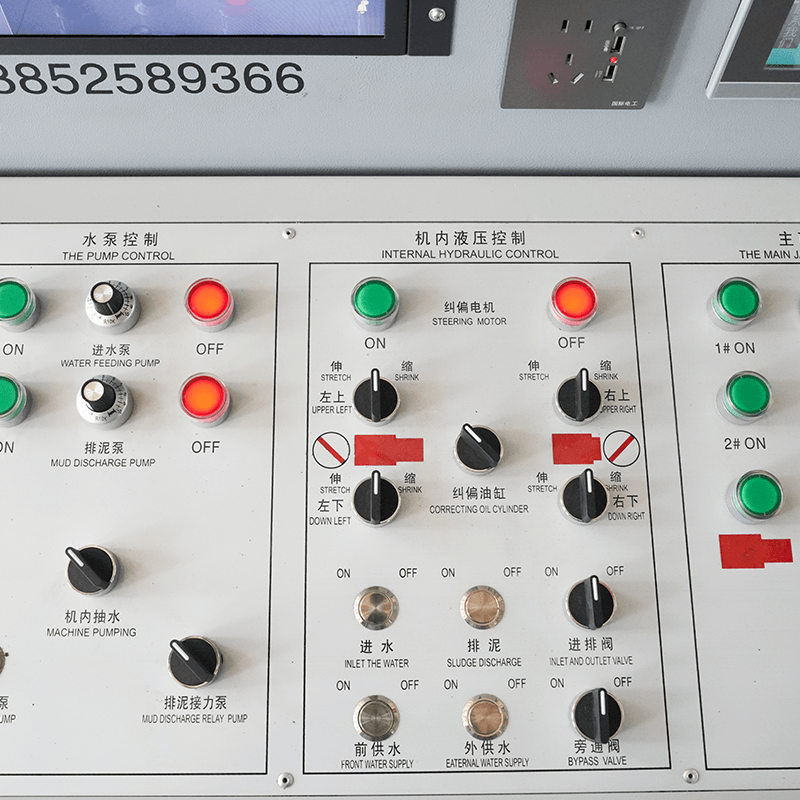

The Shield and Thrust System: The shield provides temporary support to the newly excavated tunnel walls, especially in unstable ground. A powerful hydraulic thrust system pushes the entire machine forward, bracing against the tunnel's pre-installed lining.

-

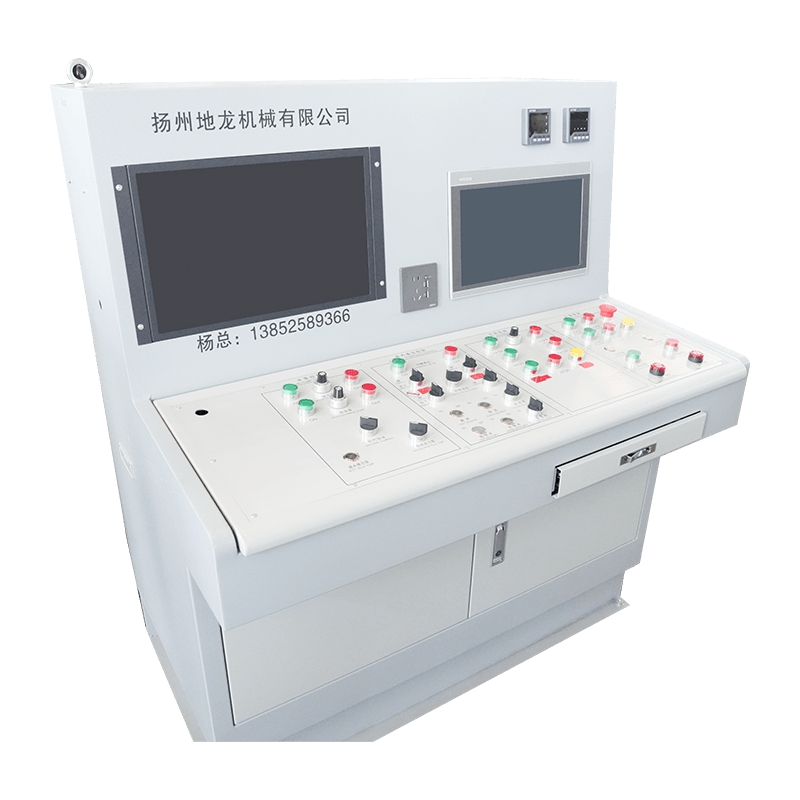

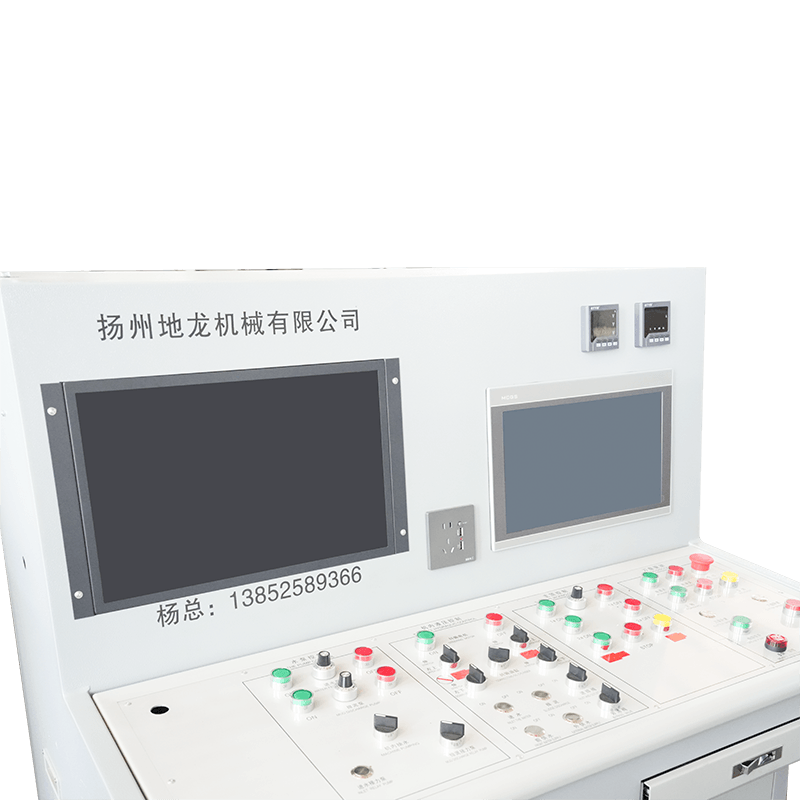

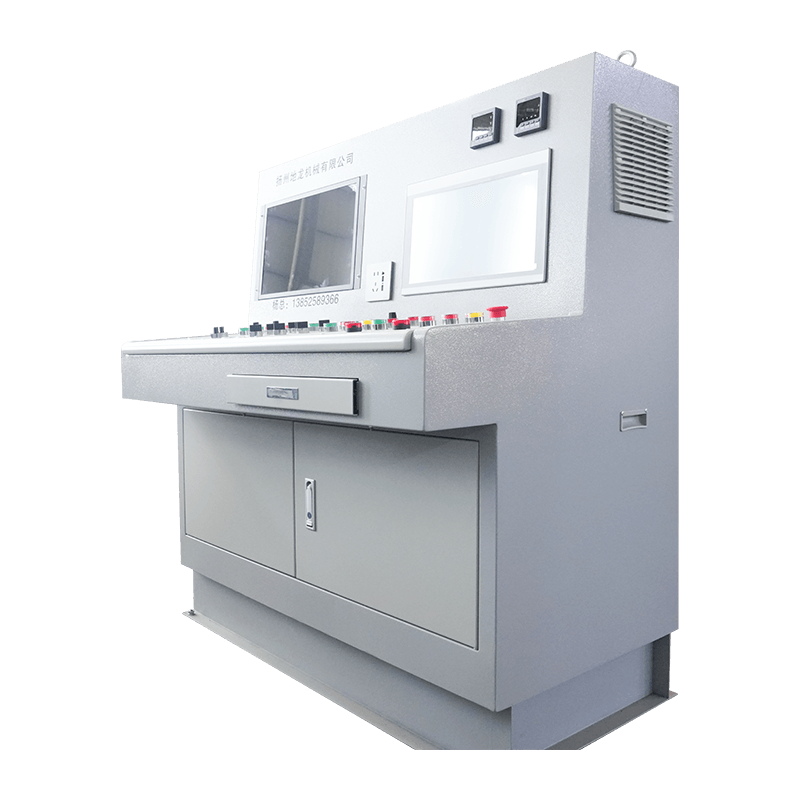

The Backup System: Located behind the shield, this system is essentially a mobile factory. It houses the muck removal system (conveyors or slurry pipes), the sophisticated control room, the electrical and hydraulic power units, and the machinery to install the precast concrete tunnel segments that form the permanent lining.

-

The Main Bearing: This large, high-precision component connects the cutterhead to the main body, absorbing immense axial and radial forces while ensuring smooth, continuous rotation.

The manufacturing process is multidisciplinary, requiring expertise in metallurgy, complex hydraulics, electrical systems, and structural mechanics. It often involves initial factory assembly and extensive no-load testing, followed by meticulous disassembly, transport to the job site, and reassembly for operation—a logistical feat in itself.

Advancements and Future Trends in TBM Manufacturing

The industry is in a constant state of innovation, driven by the increasing complexity of urban tunneling and the demand for higher efficiency, safety, and sustainability. Key advancements shaping the future of TBM Manufacturing include:

-

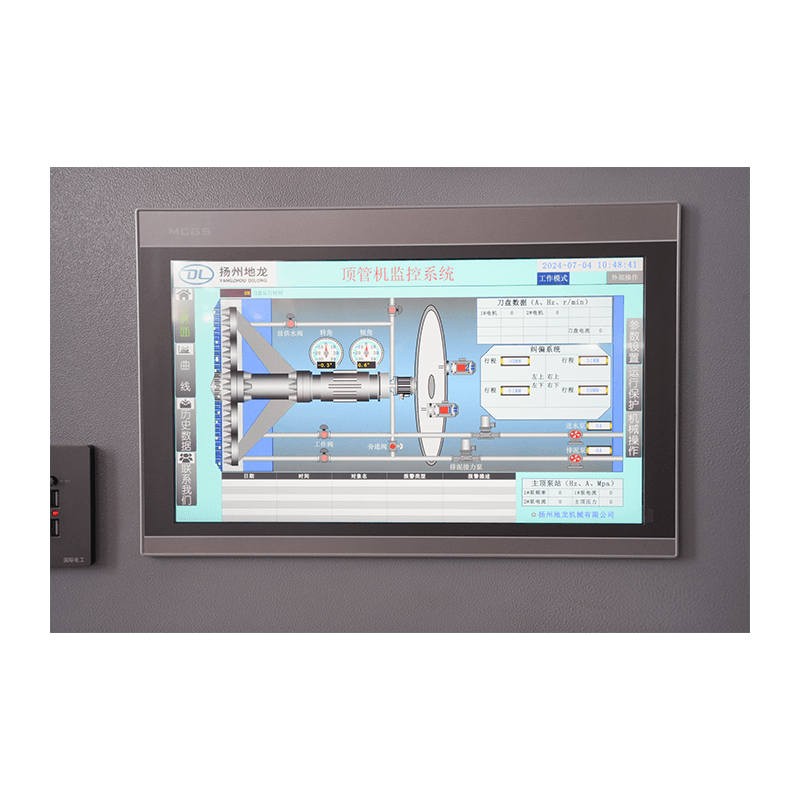

Smart Technology Integration: The adoption of Artificial Intelligence (AI), the Industrial Internet of Things (IIoT), and sophisticated data analytics is becoming standard. These technologies enable real-time geological mapping, optimize drilling parameters, and facilitate predictive maintenance, significantly reducing costly downtime.

-

Digital Twin Technology: Manufacturers are leveraging digital twin technology to create virtual models of the TBM and its operating environment. This allows for simulation, stress-testing, and optimization of the machine's design and operational plan before a single piece of steel is cut, further streamlining the manufacturing and assembly process.

-

Modular and Adaptive Designs: There is a growing focus on modular TBM designs that can be more easily transported and assembled in confined urban environments. Furthermore, multi-mode or "Crossover" TBMs, capable of switching between soft ground (Earth Pressure Balance or Slurry Shield) and hard rock tunneling, are becoming essential for projects that traverse highly variable geology.

-

Sustainability Focus: Innovations are being introduced to enhance sustainability, such as incorporating more energy-efficient electric drives instead of traditional diesel engines and developing advanced systems for managing excavated material and wastewater.

The global TBM market continues to grow, fueled by rapid urbanization and massive governmental investments in smart city infrastructure worldwide. As engineers push the boundaries of what can be built beneath our cities, the role of advanced and reliable TBMs, and the ingenuity of TBM Manufacturing, remains indispensable for shaping the underground future.

English

English  русский

русский  عربى

عربى