The construction world's relentless pursuit of efficient and minimally disruptive methods for installing underground utilities and tunnels has led to the development of highly specialized machinery. Among these innovations, the Rock Pipe Jacking Machine stands out as a crucial technology for projects involving challenging geological conditions. This powerful piece of equipment is designed to excavate and simultaneously install pipe sections in hard rock or mixed-face environments, offering a robust alternative to traditional open-cut trenching or conventional tunneling methods.

Core Function and Mechanism

The primary function of a Rock Pipe Jacking Machine is to create a precisely bored tunnel while advancing pre-cast pipe sections from a launch shaft toward a reception shaft. The machine operates on the principle of thrust and excavation:

-

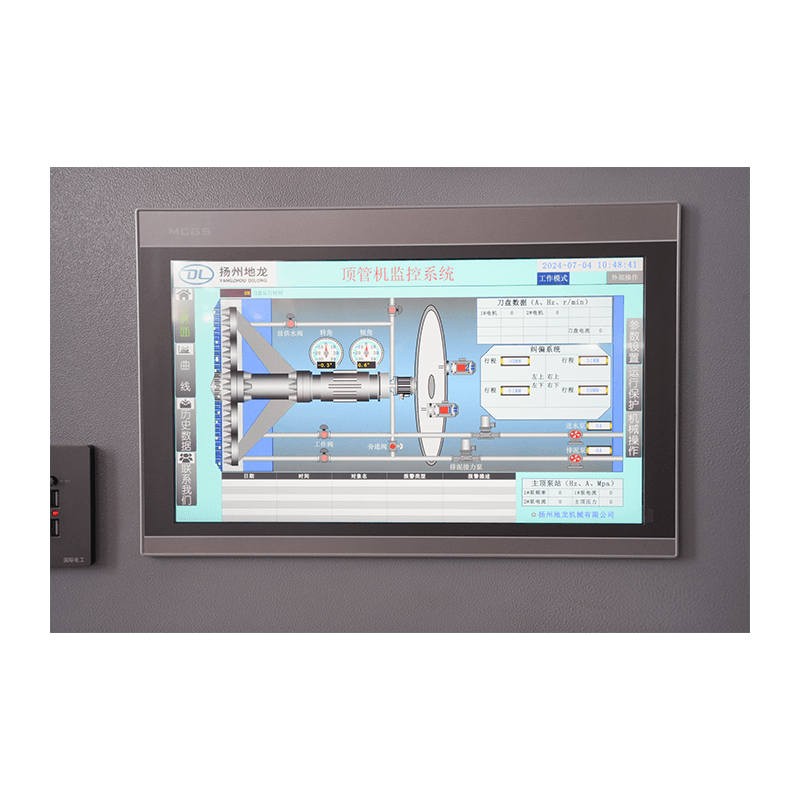

Excavation Head: At the front of the machine, a rotating cutter head, often equipped with specialized disc cutters made of hardened steel, grinds, crushes, and removes the rock face. The design of this head is highly dependent on the rock's geological characteristics, such as its strength (Uniaxial Compressive Strength or UCS) and abrasiveness.

-

Muck Removal: The excavated rock, known as "muck," is collected within the machine's chamber. Depending on the design and rock type, this material is then continuously transported back to the launch shaft via a slurry system (in wet excavation) or a conveyor belt/skip system (in dry excavation).

-

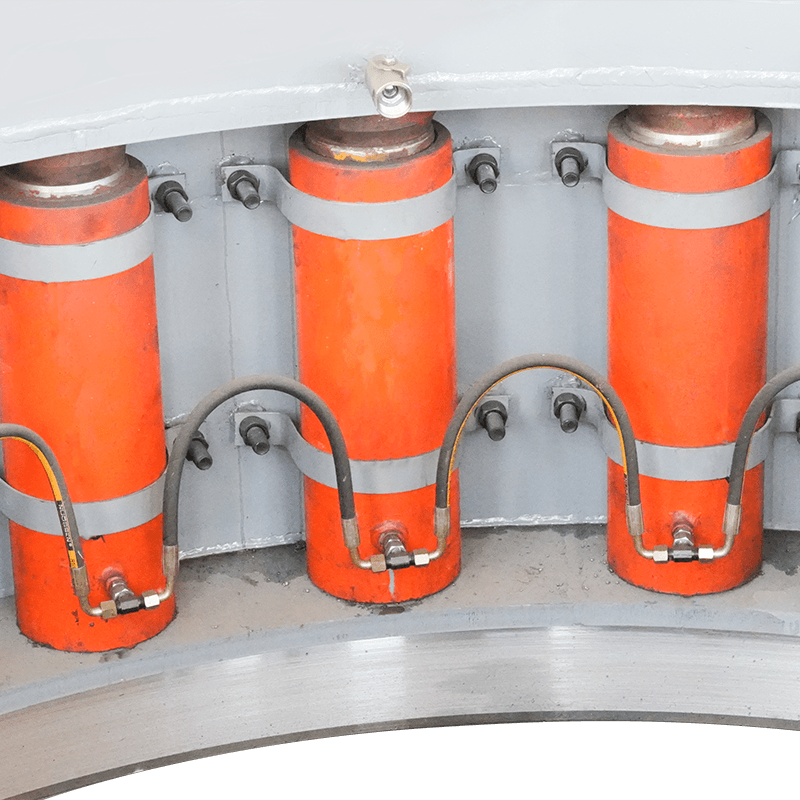

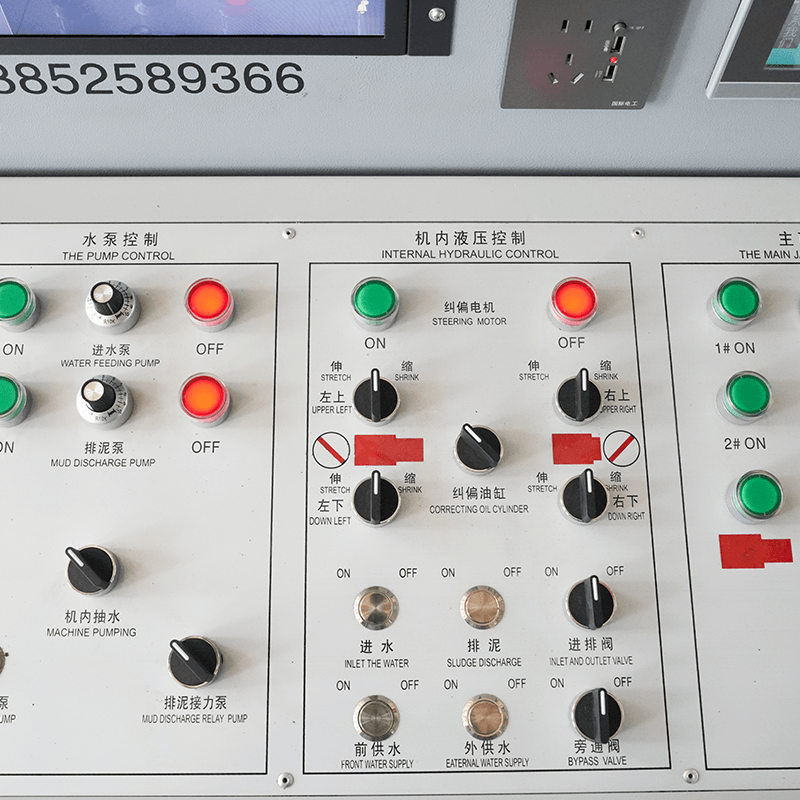

Jacking System: The machine is driven forward by powerful hydraulic jacks located in the launch shaft. These jacks push against a thrust block (the stable wall of the launch shaft) and apply immense force to the pipe string, which in turn pushes the machine head through the ground.

-

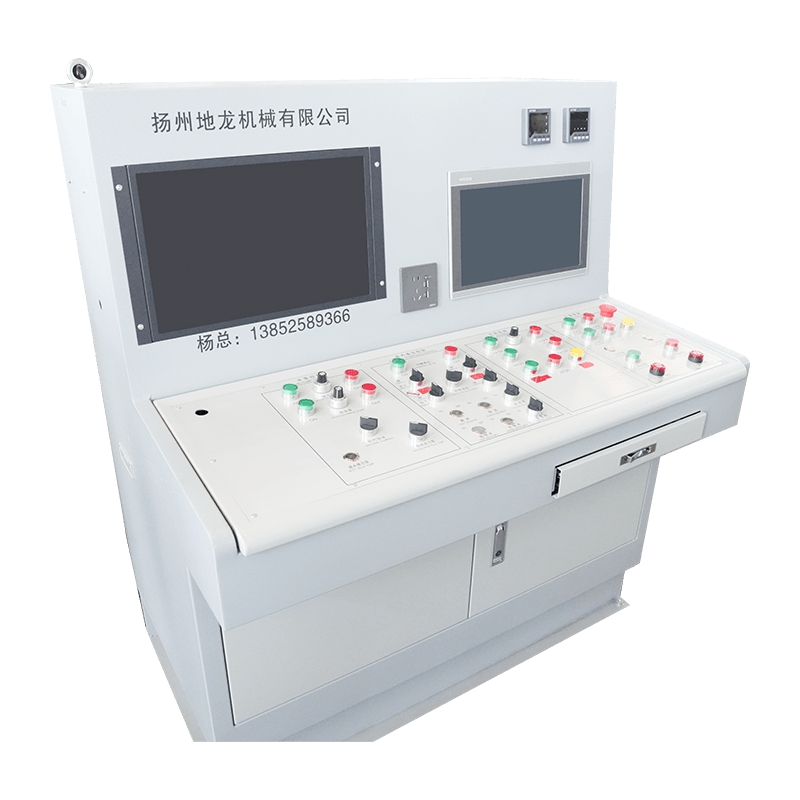

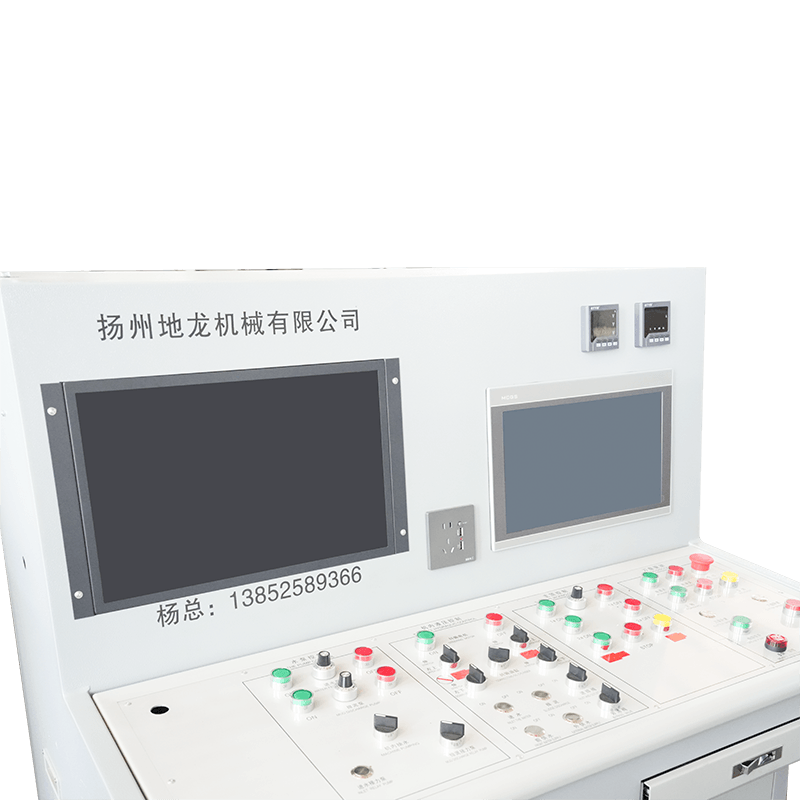

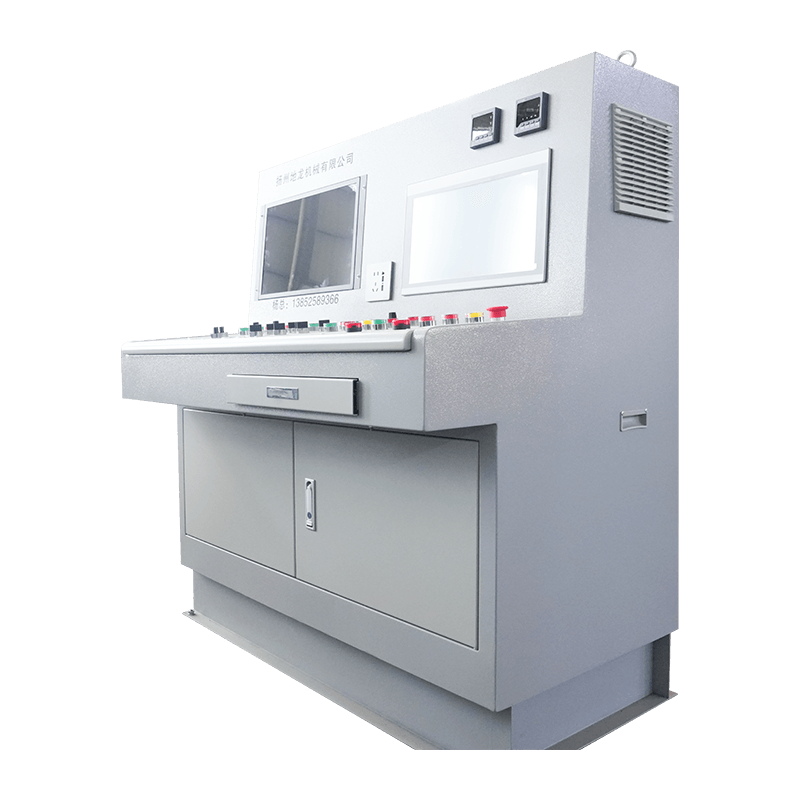

Steering and Guidance: Sophisticated laser guidance systems and articulation joints within the machine body allow operators to precisely control the machine's alignment, ensuring the installed pipeline meets stringent design tolerances for line and grade.

Key Features for Rock Conditions

What distinguishes the Rock Pipe Jacking Machine from standard earth boring or microtunneling equipment are the specific features tailored for drilling through solid rock:

-

Robust Structure and High Thrust Capacity: These machines are built with significantly reinforced structures to withstand the high forces required to crush and break rock. The hydraulic jacking systems provide hundreds, sometimes thousands, of tons of thrust.

-

Disc Cutters: Unlike drag bits or soil-cutting teeth used in soft ground, the cutter head employs hardened disc cutters. These cutters operate by concentrating high pressure onto the rock surface, creating tensile failure and chipping the rock away—a highly efficient method for hard geology .

-

Maintenance and Intervention: Working in hard rock leads to rapid wear on cutting tools. Many advanced Rock Pipe Jacking Machines incorporate features allowing for cutter inspection, repair, or replacementunder pressure(i.e., from within the machine), minimizing downtime and ensuring worker safety.

-

Grouting System: As the pipe string advances, the annular gap (the space between the excavated tunnel wall and the outside of the pipe) must be filled. The machine integrates a grouting system to inject specialized cementitious grout, which provides structural support to the pipe and prevents settlement of the ground above.

Applications and Benefits

The primary application for a Rock Pipe Jacking Machine is in areas where hard rock must be traversed, and surface disruption is unacceptable. This includes:

-

Urban Infrastructure: Installing deep sewer lines, water mains, or utility conduits beneath busy roadways, railways, or sensitive environmental areas.

-

Transportation Tunnels: Creating pedestrian, cycle, or short vehicle underpasses.

-

Drainage and Outfall Structures: Constructing tunnels for stormwater management or wastewater discharge, particularly through coastal or mountainous rock formations.

The key benefits of utilizing a Rock Pipe Jacking Machine over drill-and-blast or other tunneling techniques are reduced vibration, minimal surface disturbance, high accuracy, and enhanced safety for workers, making it the preferred method for complex, large-diameter pipeline installations in demanding geotechnical environments.

English

English  русский

русский  عربى

عربى