The art and science of underground construction have been revolutionized by the tunnel boring machine (TBM). These mechanical marvels, often referred to as "moles," have become the go-to solution for creating long, precise tunnels, particularly when faced with the formidable challenge of boring through solid rock.

The Challenge of Hard Rock

Rock tunneling presents a unique set of obstacles. The immense strength and abrasive nature of the ground require a different approach than tunneling through soft soil. While traditional "drill and blast" methods are still used, they are often slower, riskier, and cause significant ground vibration, making them unsuitable for urban areas or projects where geological stability is paramount.

This is where the specialized tunnel boring machine for rock tunneling comes into its own. Designed to withstand extreme forces, these TBMs offer a faster, safer, and more controlled method of excavation. They create a clean, circular tunnel face with minimal disturbance to the surrounding rock mass, which is critical for long-term tunnel stability.

Anatomy of a Rock-Boring TBM

A rock-specific TBM is a complex piece of engineering, built to crush and grind its way through even the hardest granite. The key components include:

-

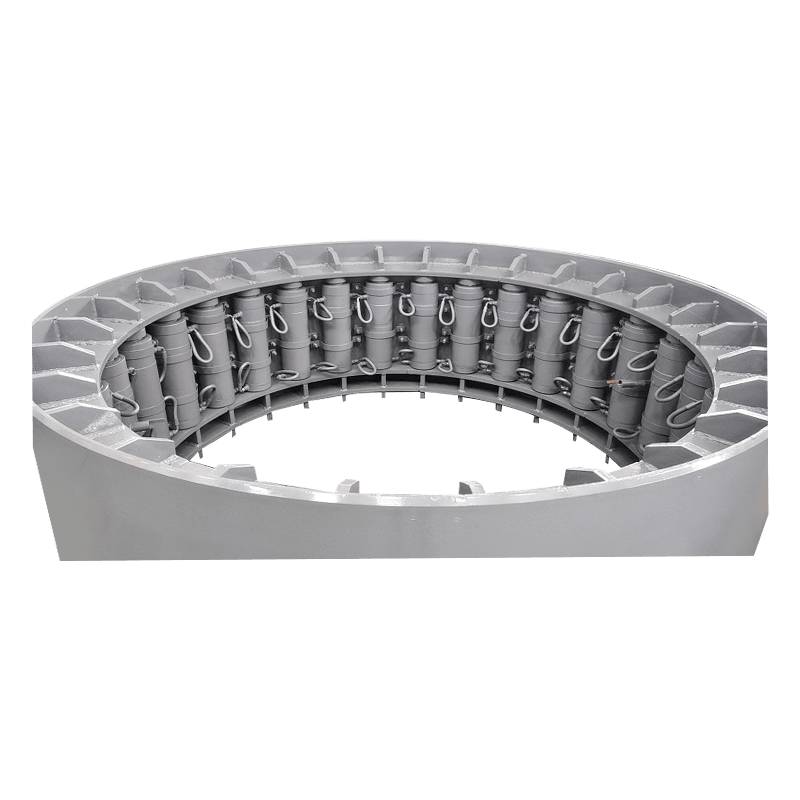

Cutterhead: This is the most crucial part, a massive rotating disk mounted at the front of the machine. It is equipped with hardened steel disc cutters—not teeth, but a series of rolling disks that apply immense pressure to the rock face. As the cutterhead rotates, these cutters fracture the rock, causing it to break away in small chips.

-

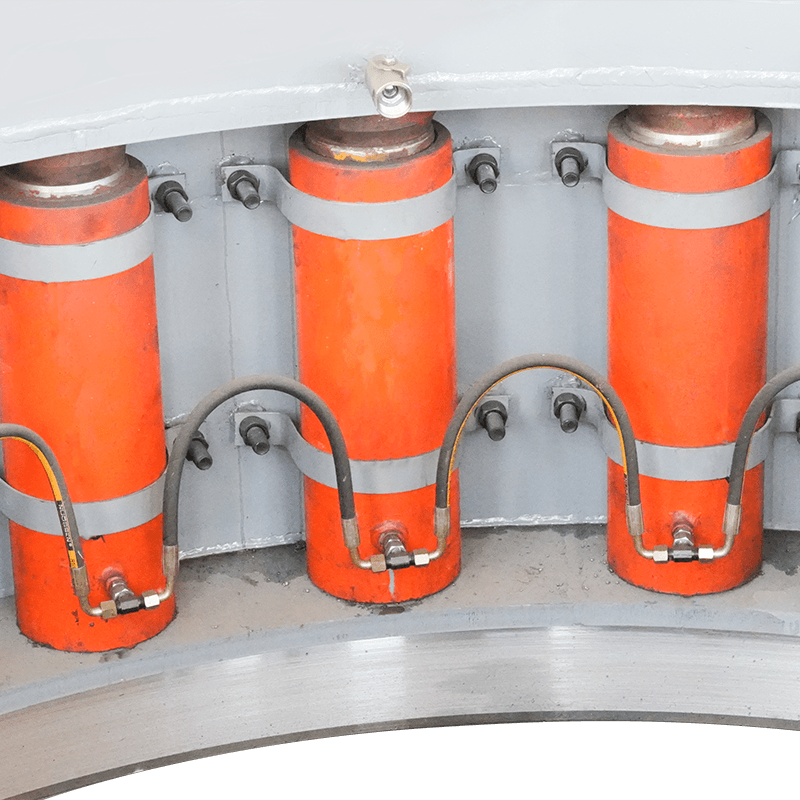

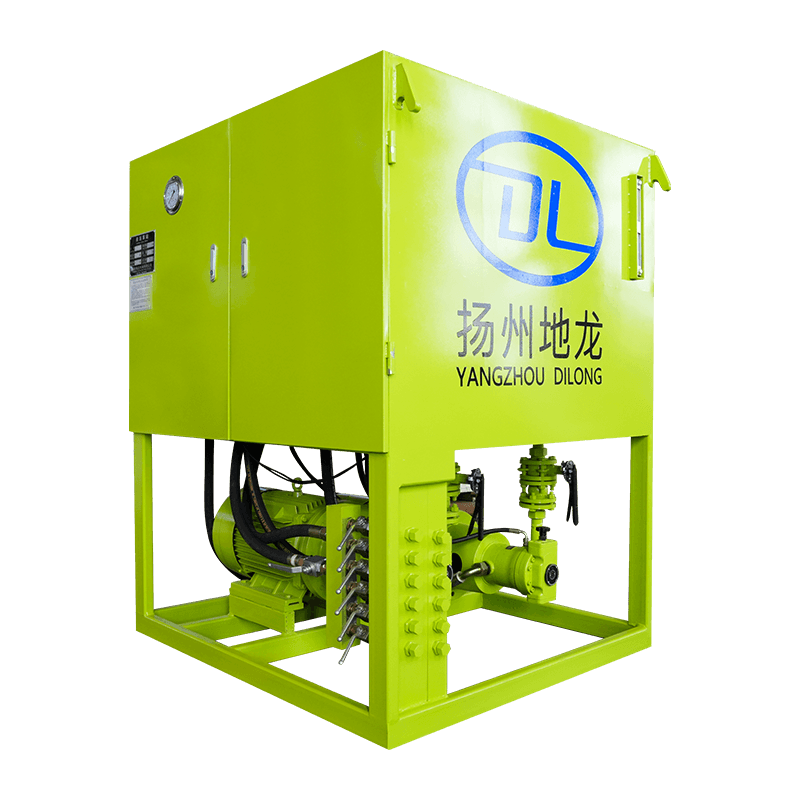

Thrust System: To generate the necessary force, powerful hydraulic cylinders push the cutterhead forward. This forward thrust is reacted against the tunnel walls or against a previously installed tunnel lining.

-

Muck Removal System: The excavated rock chips, known as "muck," fall into buckets on the cutterhead and are then transported to the back of the machine. This is typically done via a screw conveyor or a series of conveyor belts, which carry the material out of the tunnel.

-

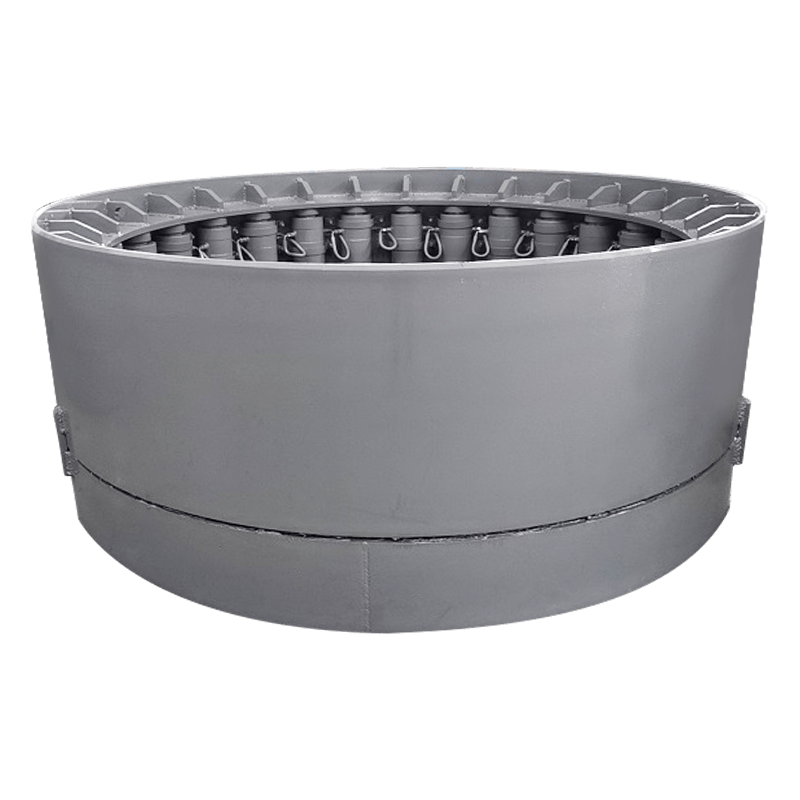

Gripper System: Many rock TBMs, particularly "open" or "gripper" TBMs, use a powerful gripper system. These machines anchor themselves to the tunnel walls with hydraulic pads, providing a stable base to push the cutterhead forward.

Types of Rock Tunneling TBMs

The choice of a tunnel boring machine depends heavily on the specific rock geology. Not all rock is the same; some is competent and stable, while other formations may be fractured or contain groundwater.

-

Main Beam TBMs (Open TBMs): These are the most common type for hard, stable rock. They have an open structure behind the cutterhead, allowing crews to install rock bolts, mesh, and shotcrete to support the tunnel walls as the machine advances. This design is highly efficient and offers excellent visibility of the geology.

-

Single Shield TBMs: When the rock is less stable and prone to spalling or collapse, a shielded machine is a safer choice. The shield, a protective steel casing, extends over the TBM's body, protecting the crew and equipment. This type of tunnel boring machine installs pre-cast concrete segments to create a permanent lining immediately behind the shield as it advances.

-

Double Shield TBMs: These machines combine the best features of both open and single-shield designs. They can operate in two modes: a "gripper" mode for stable rock and a "shielded" mode for less stable areas. The main advantage of a double shield tunnel boring machine is its ability to install tunnel segments simultaneously with the boring process in stable rock, leading to very high advance rates.

The continued evolution of the tunnel boring machine has made it possible to tackle increasingly difficult and long rock tunneling projects, from trans-mountain railways and deep-level subway lines to critical water and utility infrastructure. As engineers continue to push the boundaries of what's possible, these subterranean titans will remain at the forefront of modern civil engineering.

English

English  русский

русский  عربى

عربى