What is Pipe Jacking? The Basics of Trenchless Technology

Imagine needing to install a massive new water pipe, sewer line, or utility conduit deep beneath a bustling city street, a major highway, or even a sensitive environmental area. Digging a huge, open trench (known as “cut-and-cover”) for miles would be disruptive, expensive, and sometimes impossible. This is where trenchless technology comes in, and the Pipe Jacking method is one of its workhorse champions.

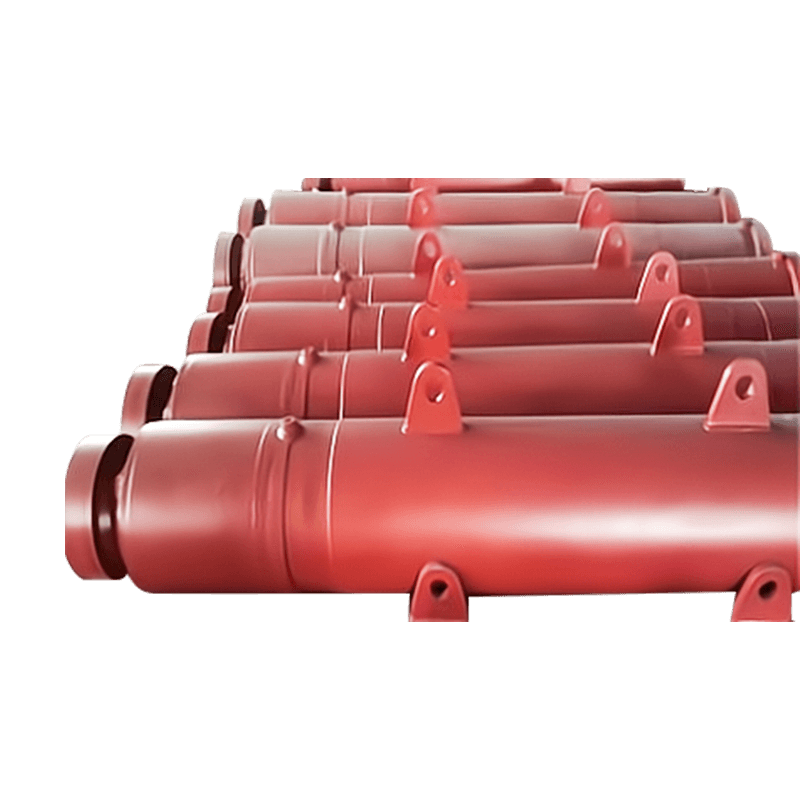

In essence, pipe jacking is a technique for installing pre-cast pipe sections by driving them horizontally through the ground from a starting pit to a reception pit. A powerful machine is placed at the front end of the pipe string, and hydraulic jacks push the entire pipeline forward. The soil or rock is excavated by the machine and then removed back through the installed pipe.

Meeting Resistance: Why We Need a Rock Pipe Jacking Machine

The standard pipe jacking method works well in soft soils like clay or sand. But what happens when the tunneling machine hits solid bedrock, hard-packed shale, or tough sandstone? That’s when the job requires a specialized tool: the Rock Pipe Jacking Machine, often a type of Microtunnel Boring Machine (MTBM) designed for hard rock.

The Challenge of Hard Rock

Hard rock is dense, abrasive, and extremely strong. A typical soft-ground machine’s cutters would quickly wear out, and its power would be insufficient to chip and grind the rock face. Rock tunneling demands a completely different approach to excavation.

How the Rock Machine Works

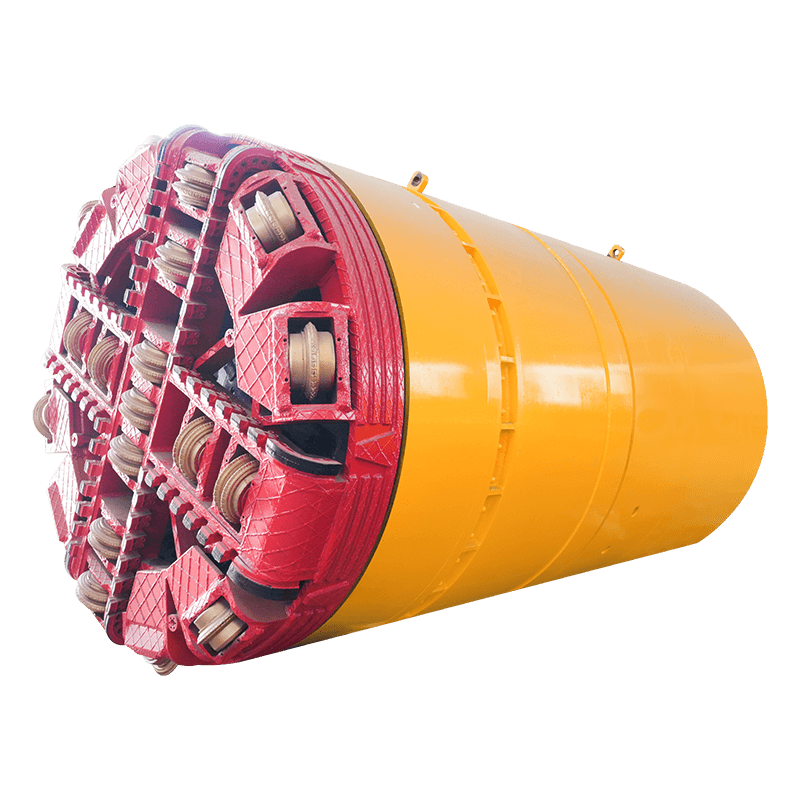

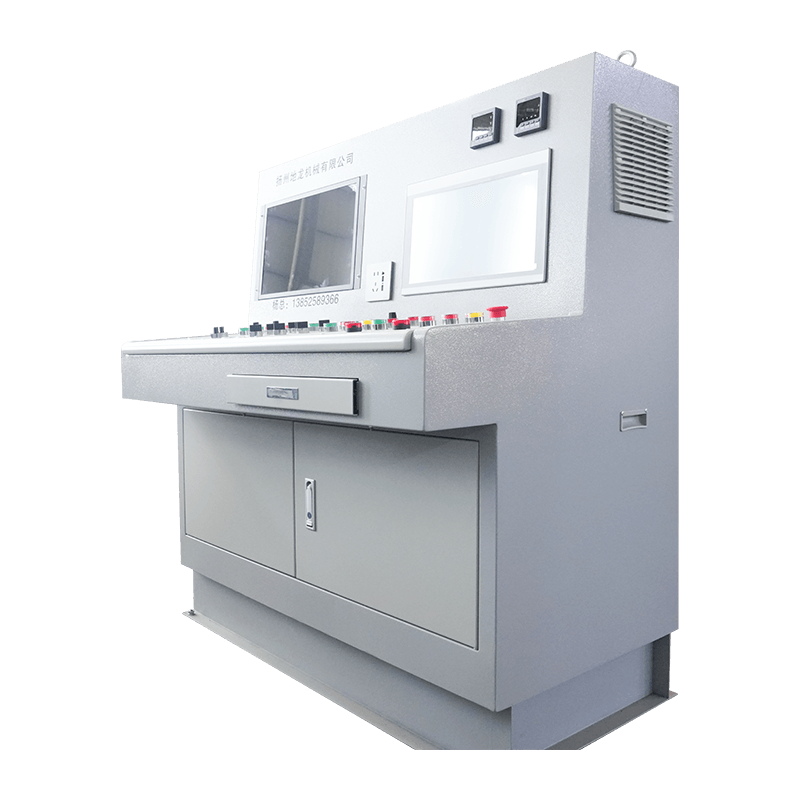

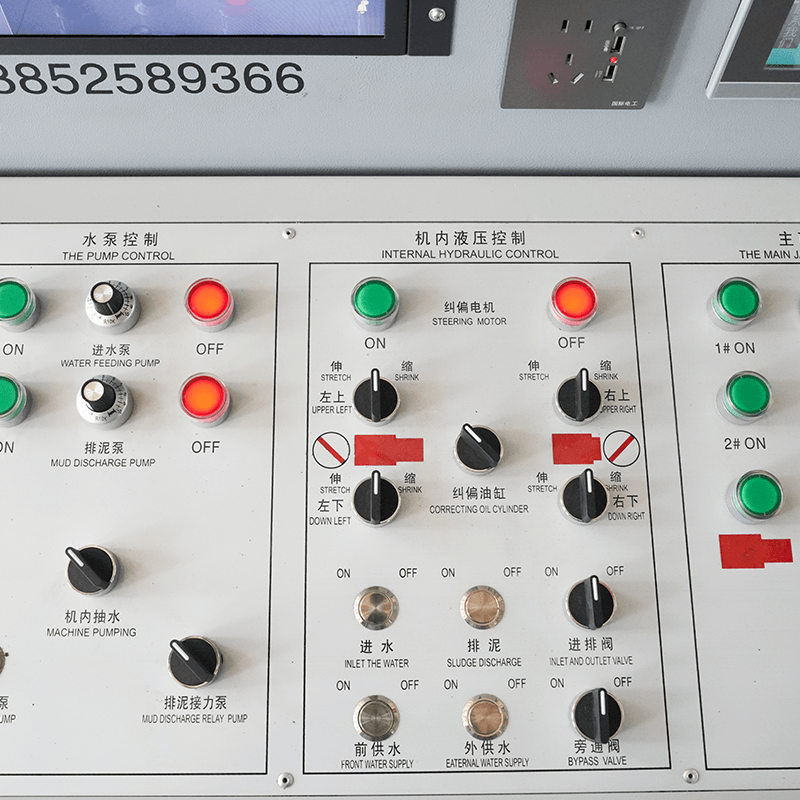

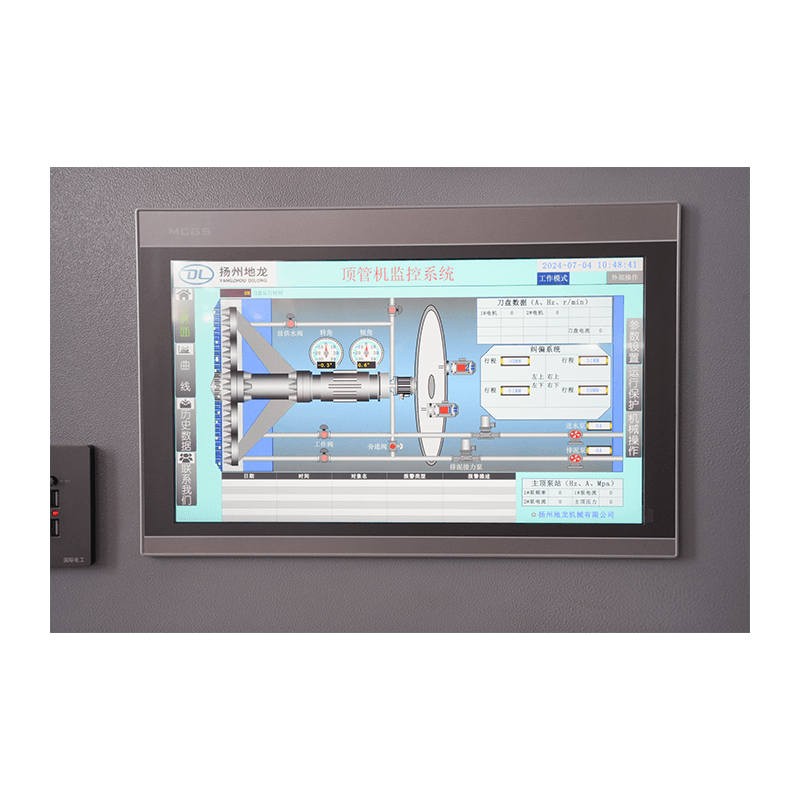

The Rock Pipe Jacking Machine is essentially a small, remotely-controlled Tunnel Boring Machine (TBM) attached to the front of the pipeline.

Cutterhead Design

The heart of the machine is the cutterhead. Unlike soft-ground machines that might use scrapers or shovels, the rock machine’s cutterhead is equipped with extremely tough, rotating discs called disc cutters.

- Disc Cutters: These steel wheels with hardened edges are pressed against the rock face under massive force. As the cutterhead rotates, the discs create tiny, high-stress fractures in the rock. The rock doesn’t get ground down; it actually spalls (chips or breaks off) in front of the disc cutters. This process is highly efficient and minimizes wear compared to pure grinding.

Spoil Removal

As the rock is fractured, the resulting small pieces, known as spoils or muck, fall into the cutterhead chamber. From there, it is mixed with a specialized drilling fluid (slurry) and pumped back through a pipeline to the surface, where it is treated and separated.

The Jacking System

The entire process is driven by the jacking system located in the starting pit. Powerful hydraulic rams push the first pipe section, which in turn pushes the machine and the entire string of pipes. As the machine excavates, the jacks advance the pipe string into the newly created tunnel.

Key Advantages: Why Rock Jacking is a Game-Changer

Using this advanced technology offers significant benefits compared to traditional open-cut methods, especially in urban or challenging environments.

1. Minimal Surface Disruption

The most obvious benefit is that the work takes place entirely underground. There are no long, open trenches, meaning traffic flow is maintained, businesses remain open, and surface ecosystems are undisturbed. This is invaluable in densely populated areas.

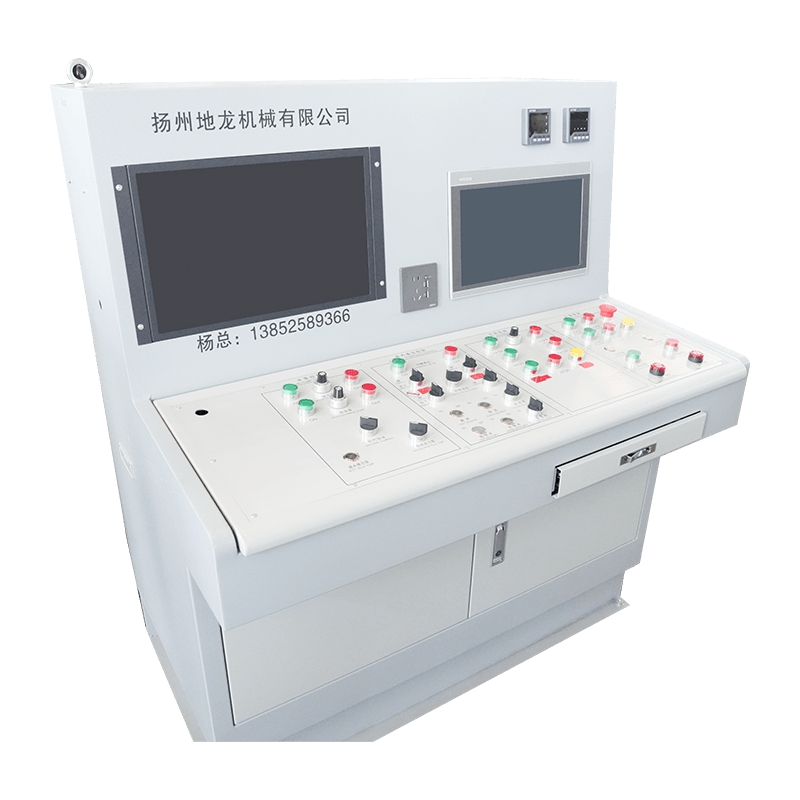

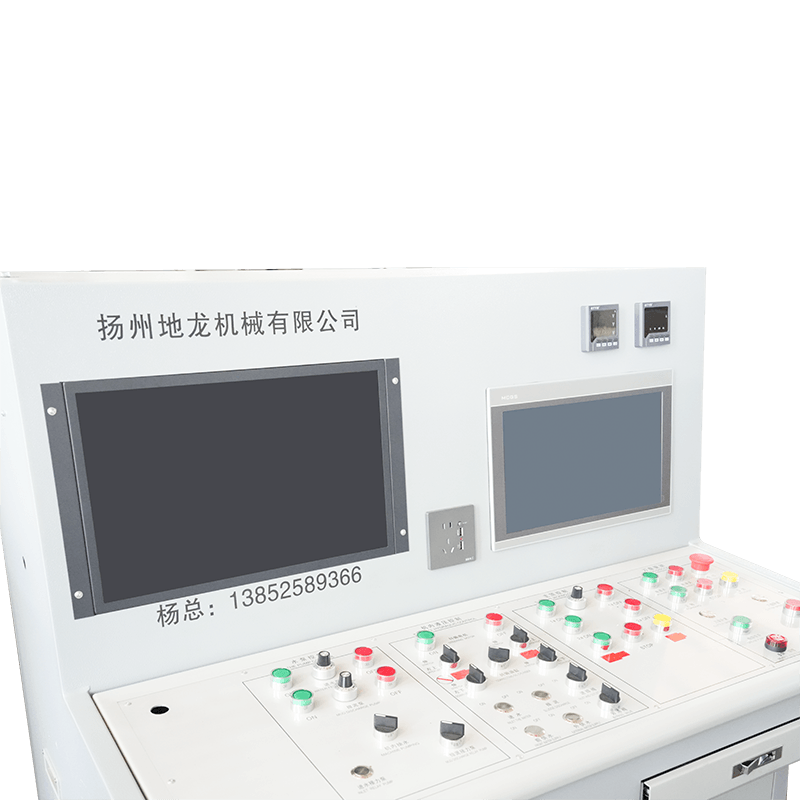

2. High Accuracy and Control

Rock Pipe Jacking Machines are guided by sophisticated laser or gyroscopic navigation systems. The machine’s operator, working from a control cabin on the surface, can make real-time steering adjustments. This allows for the installation of utilities with an incredibly high degree of precision over long distances, sometimes only millimeters from the planned alignment.

3. Safety and Environmental Benefits

Because workers are not required to be inside the excavation face—the machine is remotely controlled—the process is inherently safer. Furthermore, by avoiding open trenches, the risk of disturbing contaminated soil or sensitive groundwater is minimized. The excavated rock is contained and managed in a controlled manner.

The Future is Underground

Rock Pipe Jacking Machines are critical tools for modern infrastructure development. As cities become more crowded and the need for new, reliable utilities—from high-speed fiber optics to large water supply tunnels—grows, the ability to build essential infrastructure without tearing up the world above will only become more important. This hidden powerhouse is truly making a major impact, one underground segment at a time.

English

English  русский

русский  عربى

عربى