The construction of modern underground infrastructure requires methods that minimize surface disruption while maintaining high standards of accuracy and efficiency. Among the most sophisticated solutions for pipe installation is the Micro-tunneling Machine (MTBM). This technology represents a significant leap from traditional open-cut methods, offering a trenchless alternative for installing pipelines across diverse environments, from densely populated urban areas to sensitive ecological zones.

What is a Micro-tunneling Machine?

A Micro-tunneling Machine is a remotely controlled, steerable, pipe-jacking system that simultaneously excavates and installs pipe segments. The "micro" in its name primarily refers to the fact that the process is controlled from above ground and the tunnel size typically ranges from to over in diameter, which is relatively small compared to conventional Tunnel Boring Machines (TBMs) used for large metro or vehicle tunnels.

The fundamental principle involves a shield equipped with a cutting head that excavates the soil. Directly behind the shield, a string of prefabricated pipe segments (usually made of concrete or steel) is pushed forward by powerful hydraulic jacks located in a jacking shaft. The excavated spoil is continuously transported back to the launch shaft via a slurry or auger system.

Key Components and Operation

The successful operation of a Micro-tunneling Machine relies on the synergy of several critical components:

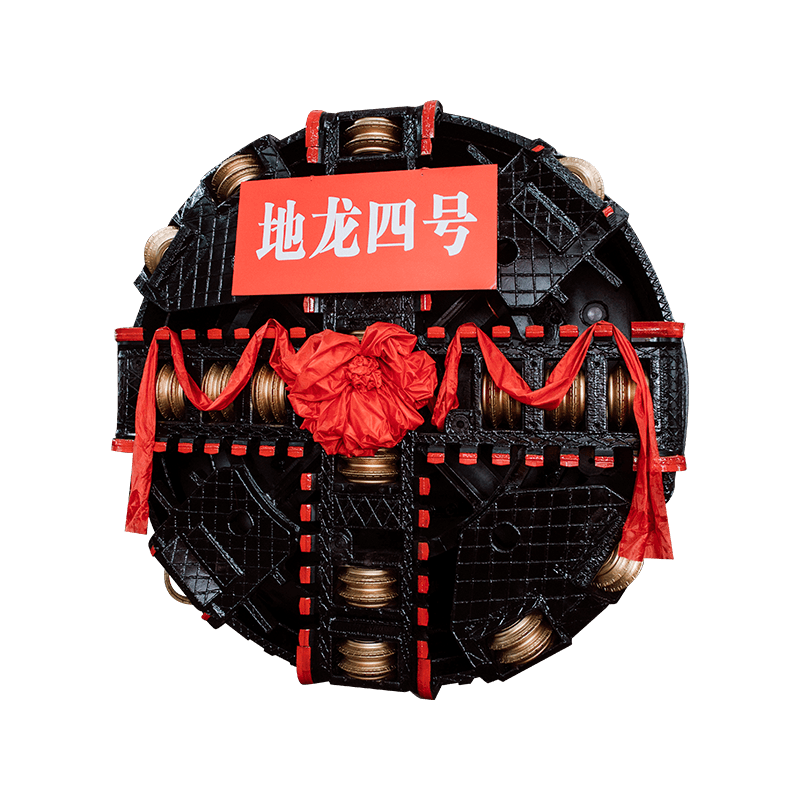

- Cutting Head (Shield): Designed to match the soil conditions, the cutting head is responsible for breaking up the ground. Different types, such as open-face, full-face, or rock-cutter heads, are used depending on whether the project is in soft ground, mixed face, or rock.

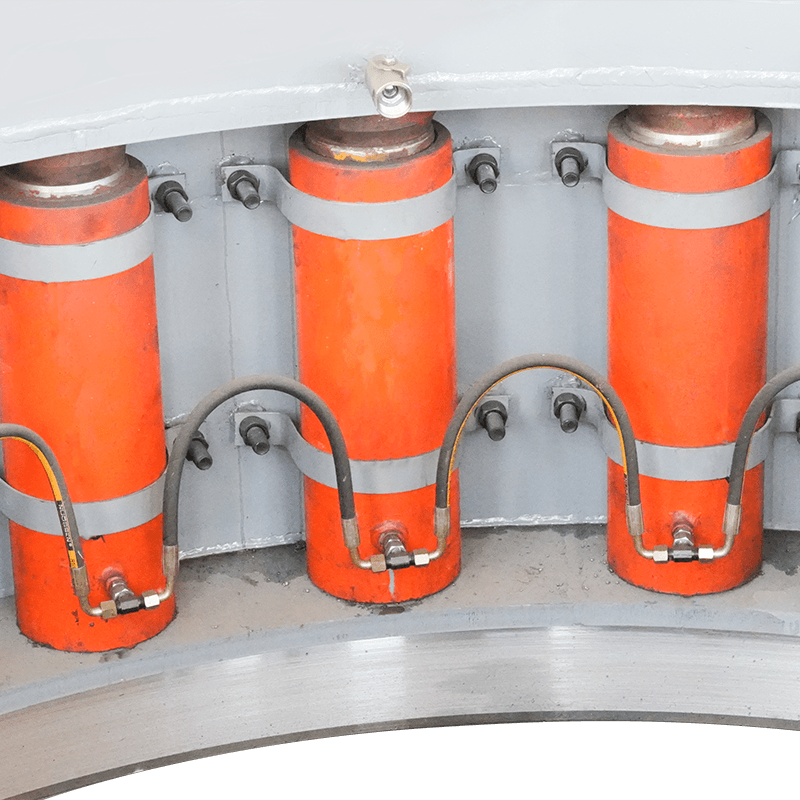

- Jacking System: A high-capacity hydraulic jacking station located in the launch shaft provides the necessary thrust force to push the shield and the entire pipe string forward.

- Spoil Removal System: This is typically a closed-loop slurry system, which pumps a fluid mixture (slurry) to the face to stabilize the excavation and transports the excavated material (spoil) back to a separation plant on the surface. For smaller bores, an auger system may be used.

- Guidance System: Precision is paramount. Modern Micro-tunneling Machine systems use laser guidance or, for longer and curved drives, more advanced gyroscopic systems to constantly monitor the machine’s position (line and grade) and correct its steering via articulation in the shield.

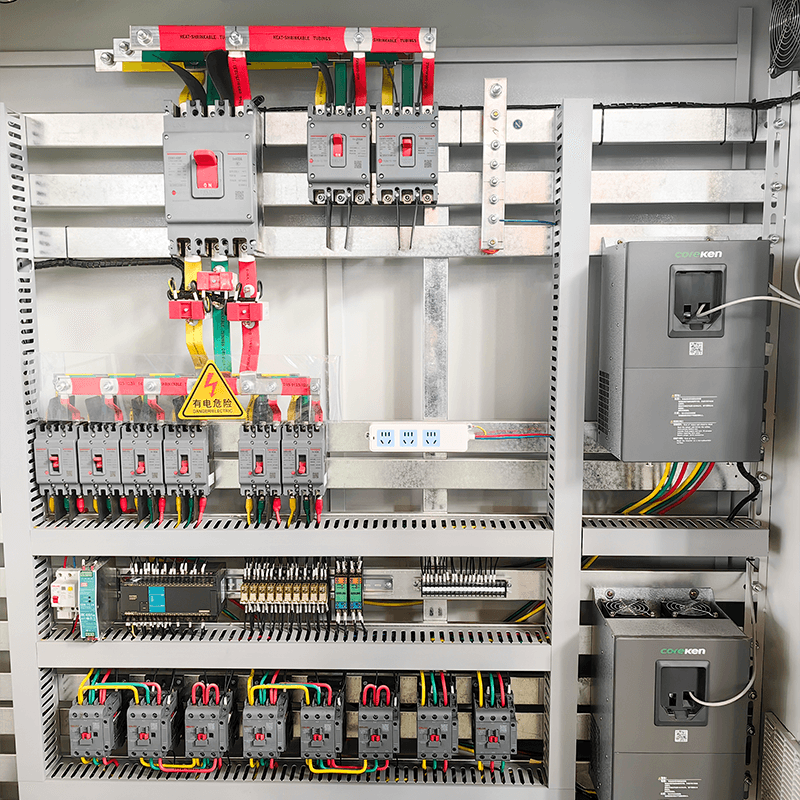

- Control Container: The entire operation is managed remotely from a surface control unit, ensuring maximum safety for personnel.

Advantages and Applications

The adoption of the Micro-tunneling Machine has grown significantly due to its compelling advantages over traditional methods:

- Minimal Surface Disruption: Since all major work occurs underground, it eliminates the need for long trenches, drastically reducing traffic disruption, noise, and environmental impact. This is particularly valuable in urban centers.

- High Precision: The advanced guidance systems allow for the installation of pipelines with exceptional accuracy in terms of line and grade, which is crucial for gravity-fed sewer systems.

- Safety: The remote-controlled nature of the Micro-tunneling Machine keeps workers out of the tunnel face, significantly enhancing job site safety.

- Versatility: The technology can handle a wide range of ground conditions, including sand, clay, rock, and high water tables, by maintaining positive face pressure.

The primary applications for the Micro-tunneling Machine include the installation of new infrastructure like:

- Sanitary and Storm Sewers

- Water and Gas Pipelines

- Utility Conduits and Cable Ducts

- Outfall Structures and Drainage Systems

The Future of Trenchless Technology

As infrastructure demands continue to rise globally, the Micro-tunneling Machine will remain a vital tool. Ongoing research is focused on developing MTBMs with increased maneuverability for tighter curves, enhanced cutting heads for challenging geology, and more efficient spoil handling systems. The relentless drive toward smarter, safer, and more sustainable construction practices guarantees the long-term importance of this precision powerhouse in the world of civil engineering.

English

English  русский

русский  عربى

عربى