The Challenge of Underground Construction

Imagine needing to install a large, robust utility tunnel—perhaps for electricity cables, water pipes, or even a pedestrian subway—right beneath a busy city street or a delicate natural environment. Digging a traditional open trench, or “cut-and-cover,” is often impossible. It would disrupt traffic, take a long time, and could destabilize nearby buildings.

Engineers needed a smarter, less invasive solution: a way to bore horizontally, push a pipe in place, and do it all without anyone on the surface knowing a huge machine was at work. This is where trenchless technology comes in, and one of its most innovative tools is the Earth Pressure Balance Rectangular Pipe Jacking Machine.

What is Pipe Jacking?

Pipe jacking is a method for installing underground pipelines. Instead of digging a massive hole from above, a special shield or cutting machine is launched from a deep pit (the “launch shaft”) and bores its way to a receiving pit. As the machine excavates, sections of pipe—sometimes hundreds of meters long—are thrust forward behind it by powerful hydraulic jacks.

The Problem with Round Pipes

For certain applications, like utility corridors or large vehicular underpasses, a circular tunnel is inefficient. A circular tunnel occupies more volume underground than the usable space it provides. A rectangular or box-shaped cross-section offers much better space utilization, maximizing the available area for cables or traffic within the same excavation height. The problem is, tunneling a rectangle is mechanically much more complex than tunneling a circle.

The Earth Pressure Balance Rectangular Pipe Jacking Machine

The machine’s full name describes its complex capabilities:

1. Rectangular Pipe Jacking:

This refers to the machine’s shape and primary function. It excavates a box-shaped hole and pushes in pre-cast rectangular concrete pipe sections. This geometry is key for high-density utility installation and pedestrian tunnels.

2. Earth Pressure Balance (EPB):

This is the genius behind the operation. When tunneling, especially in soft, wet, or unstable ground (like clay or sand), the ground pressure must be continuously balanced to prevent the tunnel face from collapsing and to stop water or soil from flooding the machine.

The EPB machine achieves this by turning the excavated soil into a paste or “soil conditioning” material. This material is kept under precise pressure within the machine’s closed excavation chamber, acting like a pressurized plug. This counter-pressure perfectly matches the surrounding earth and water pressure, ensuring the stability of the ground right above the machine. It’s like having a temporary, pressurized wall of dirt holding everything in place until the pipe is jacked forward.

3. Machine Components:

The machine is essentially a mobile factory on the cutting edge. It includes:

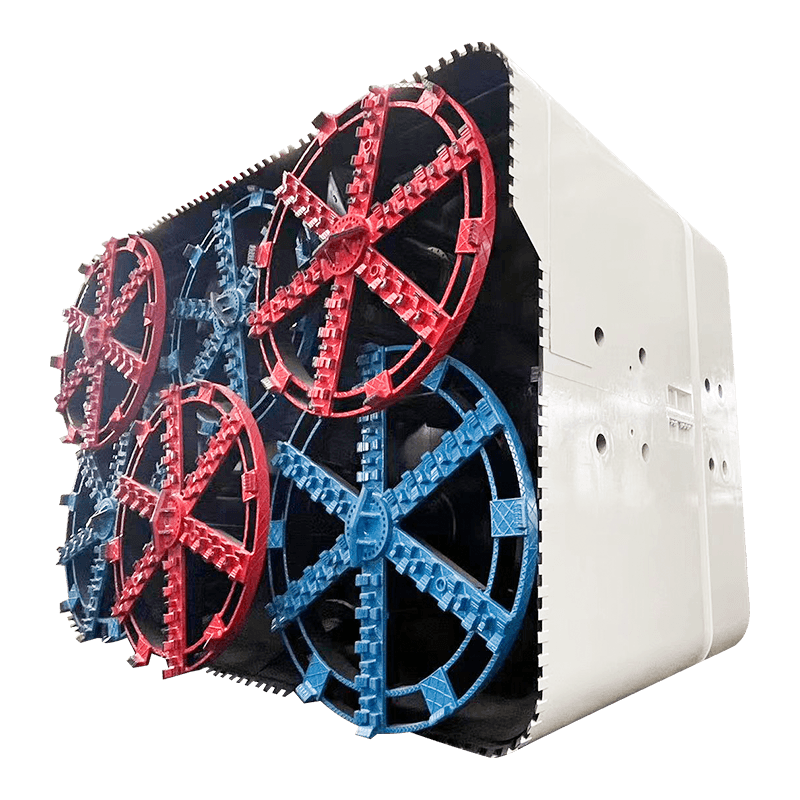

- A Rectangular Cutterhead: This is the front face, studded with rotating cutting tools that grind away the soil. Since it’s rectangular, the cutters must be arranged to cover the entire area efficiently.

- The Mucking System: This moves the conditioned soil from the cutting chamber to a disposal system, often via a conveyor belt, to the surface.

- The Steering System: Due to the rectangular shape, steering is more difficult than with a circular machine. Highly precise control systems and articulation joints are needed to keep the machine on its exact linear and vertical path.

- Hydraulic Jacks: The true power of the system. These jacks sit in the launch shaft and deliver the enormous force needed to push the entire pipeline—which can weigh thousands of tons—forward into the ground.

Why This Technology Matters

The Earth Pressure Balance Rectangular Pipe Jacking Machine represents a crucial advancement in urban infrastructure development.

Minimized Surface Disruption

Its trenchless nature means that projects can be completed with minimal impact on city life. Roads stay open, businesses continue to operate, and the public is barely aware of the massive construction occurring far beneath their feet.

Increased Safety and Efficiency

By maintaining Earth Pressure Balance, the risk of sinkholes or ground settlement—a major hazard in underground work—is drastically reduced. This stability allows for tunneling much closer to existing structures than traditional methods would permit.

Sustainable Infrastructure

Rectangular tunnels are future-proof. They offer a higher capacity for utilities and can easily accommodate upgrades or maintenance, making them an essential tool for building modern, sustainable cities that are designed to handle growing populations and technological demands without tearing up the streets.

English

English  русский

русский  عربى

عربى