Understanding the Core Mechanics of Tunnel Boring Machines (TBMs)

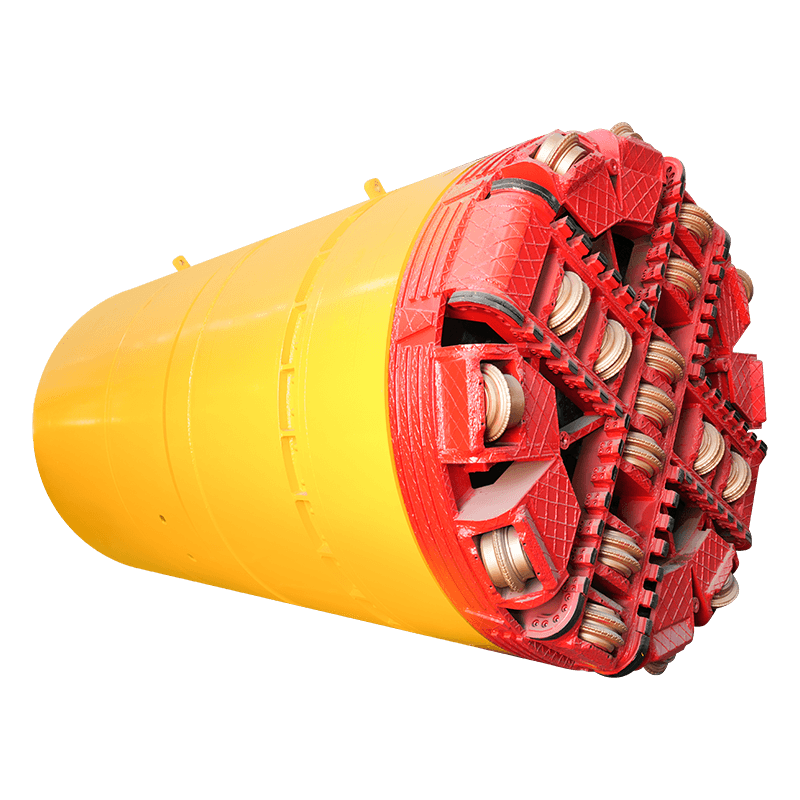

A Tunnel Boring Machine, commonly referred to as a "mechanical mole," is a sophisticated piece of engineering designed to excavate tunnels with a circular cross-section through various soil and rock strata. Unlike traditional drill-and-blast methods, a TBM offers a continuous, automated process that minimizes vibration and ground disturbance. The heart of the machine is the rotating cutting head, which utilizes disc cutters or scrapers to break down the geological face. As the head rotates, hydraulic rams provide the necessary thrust to push the machine forward, while the excavated material—known as muck—is transferred through the cutter head into a conveyor system or slurry pipeline for removal.

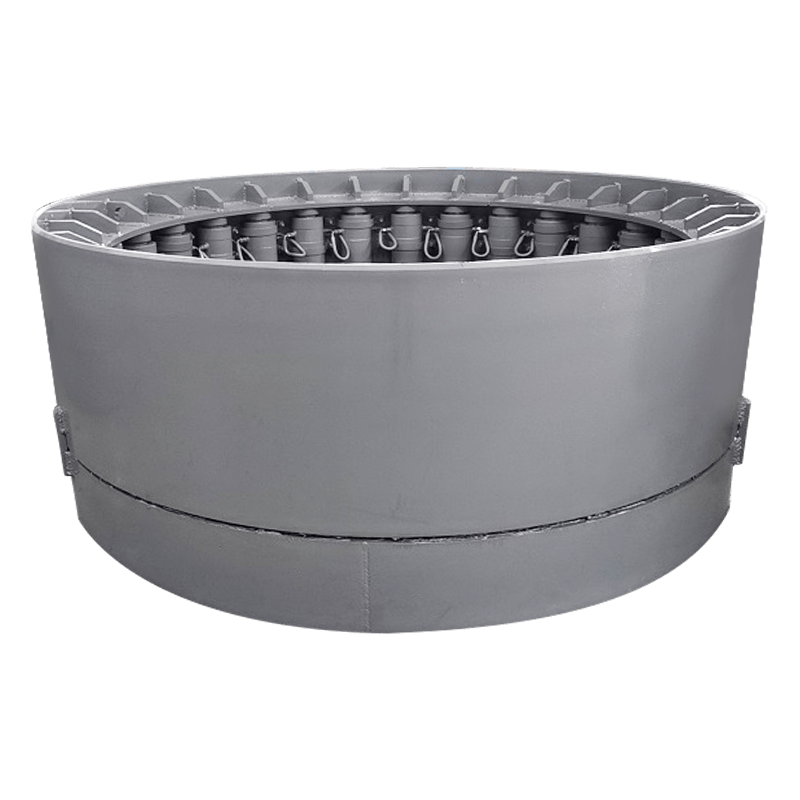

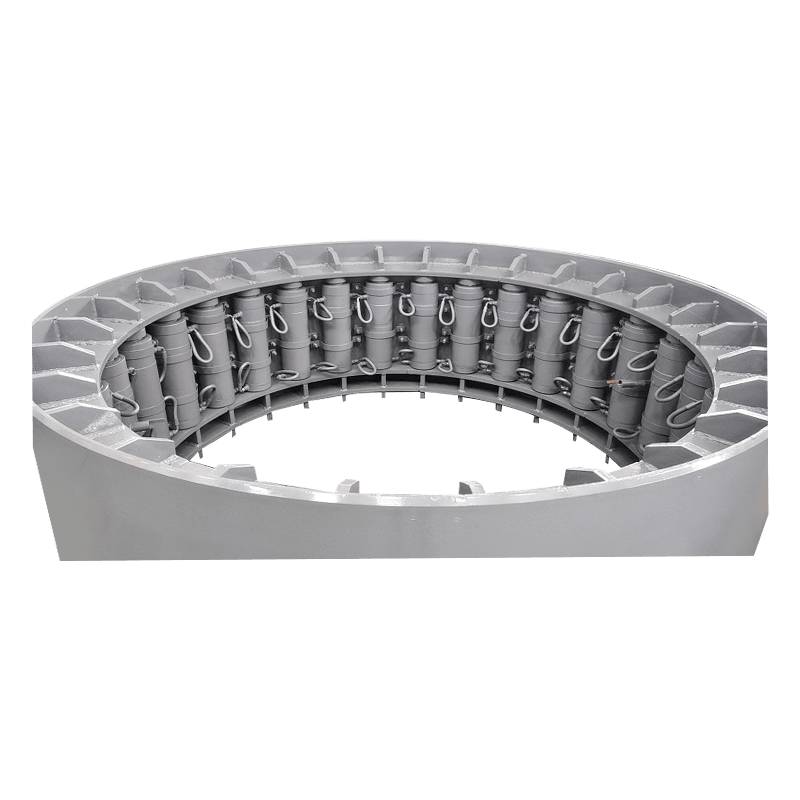

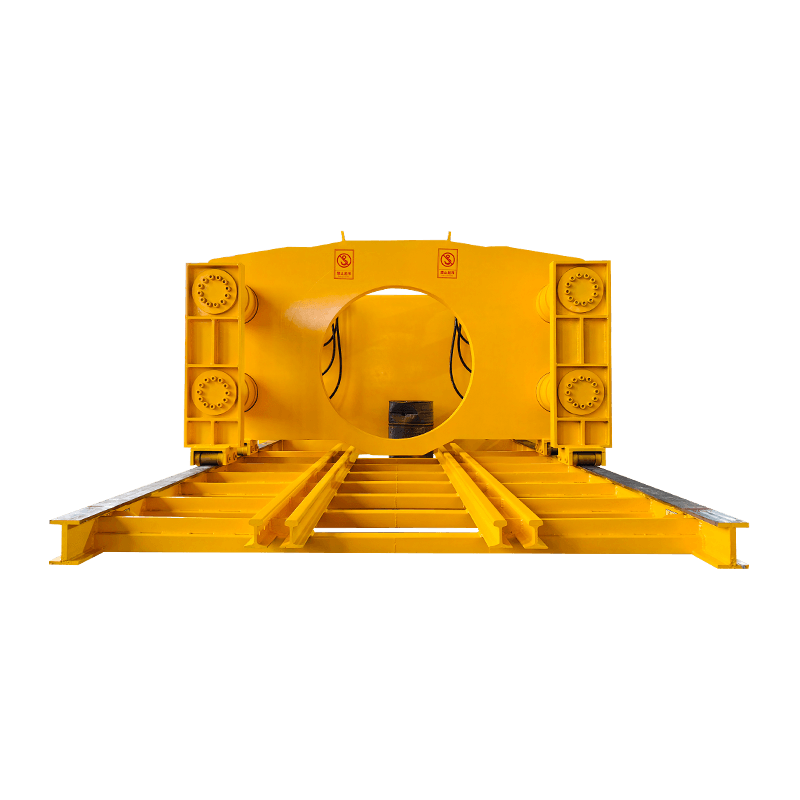

Modern TBMs are not merely excavation tools; they are mobile underground factories. As the machine advances, it simultaneously installs the tunnel lining. This is typically achieved using precast concrete segments that are lifted into place by an automated erector arm and bolted together to form a structural ring. This immediate support system is crucial for maintaining the integrity of the tunnel, especially when boring through soft ground or beneath high-density urban infrastructure where surface settlement must be strictly controlled.

Comparative Analysis of TBM Types Based on Geological Conditions

Selecting the appropriate tunnel machine depends entirely on the lithology and hydrogeological conditions of the project site. Using the wrong machine can lead to catastrophic soil collapse or excessive wear on the cutting tools. Engineers generally categorize these machines based on how they manage face pressure and debris removal.

| Machine Type | Geological Suitability | Primary Mechanism |

| Hard Rock TBM | Granite, Basalt, Limestone | Disc cutters that fracture rock through high pressure. |

| Earth Pressure Balance (EPB) | Silt, Clay, Sand | Uses excavated soil to provide counter-pressure to the tunnel face. |

| Slurry Shield TBM | Highly permeable ground / High water table | Pressurized bentonite slurry balances groundwater pressure. |

Critical Components for Precision Underground Navigation

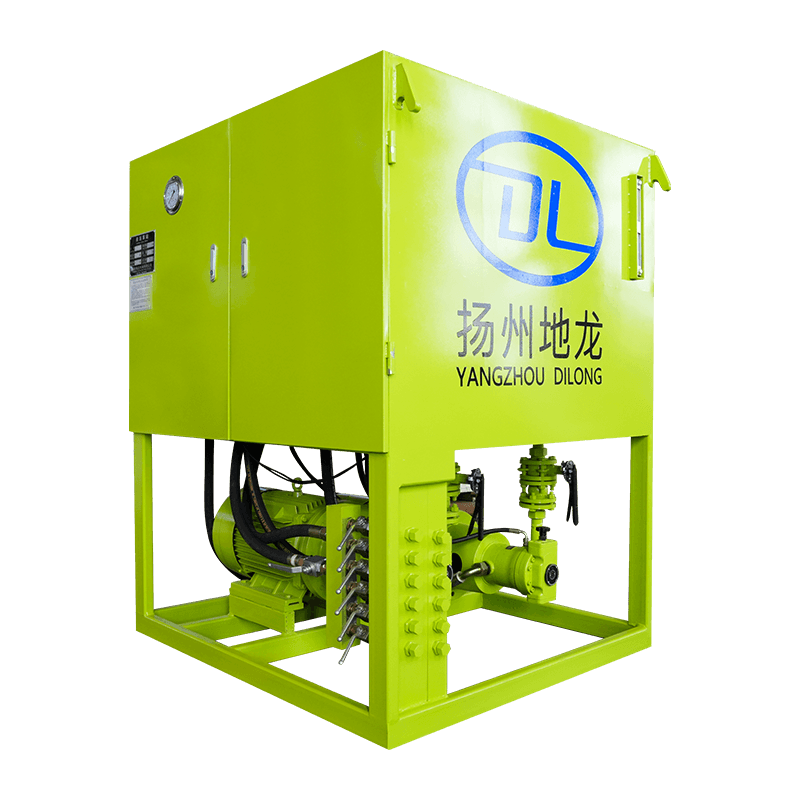

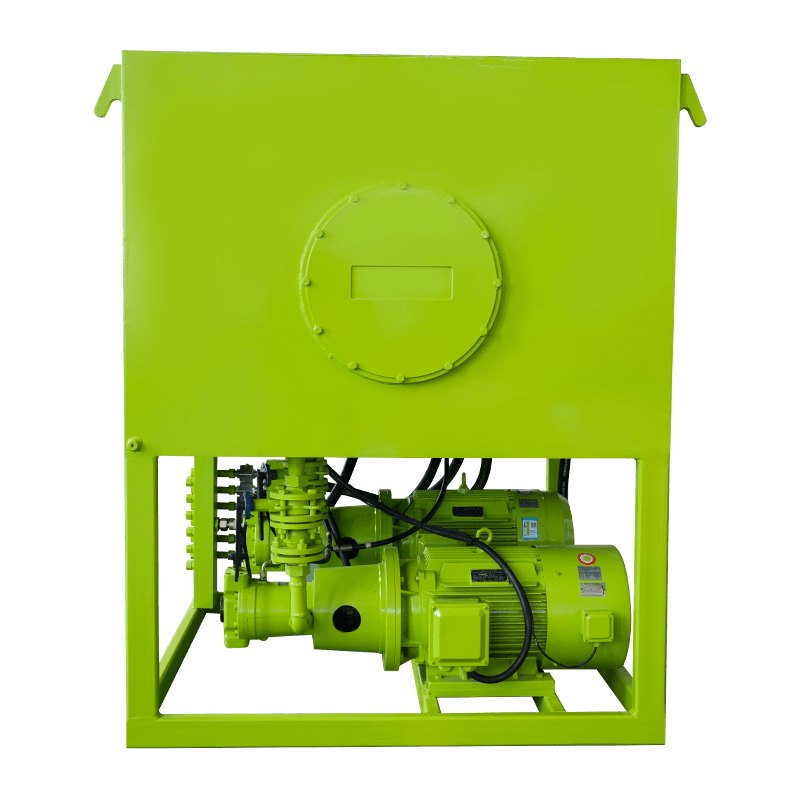

Operating a tunnel machine requires extreme precision, as even a minor deviation in alignment can compromise the entire project. This is managed through an integrated guidance system that monitors the machine's position in three-dimensional space. The following components are essential for the safe and efficient operation of the unit:

- Laser Guidance Systems: Continuously track the Z-axis and X-axis coordinates to ensure the machine follows the predetermined survey path.

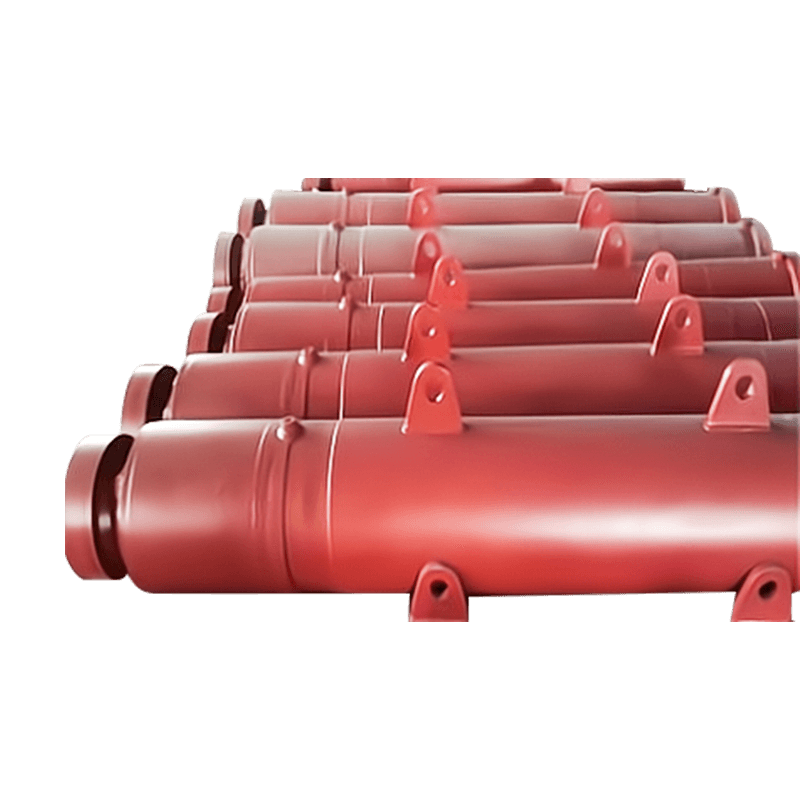

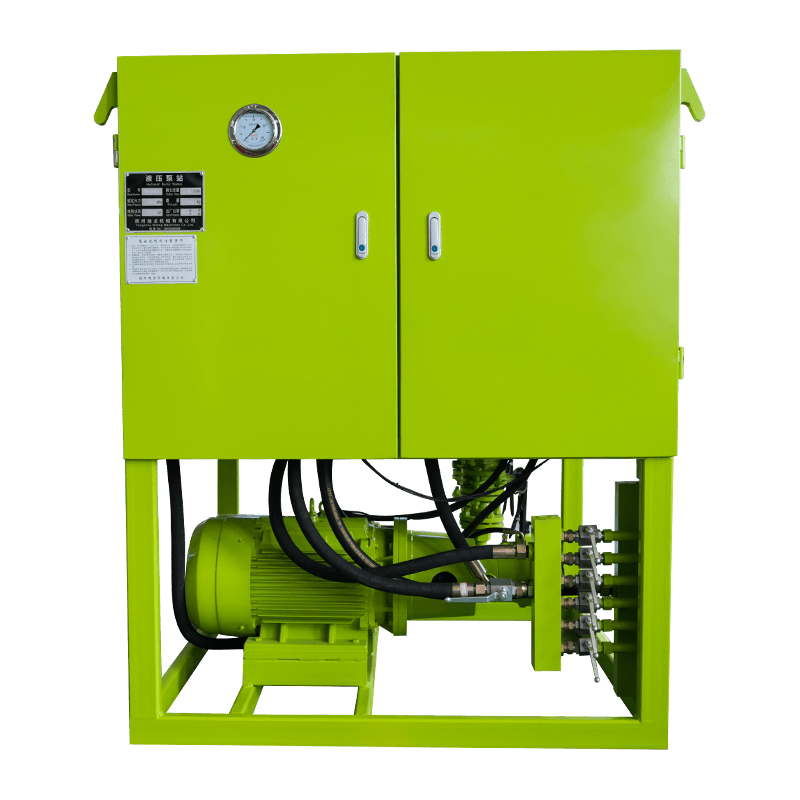

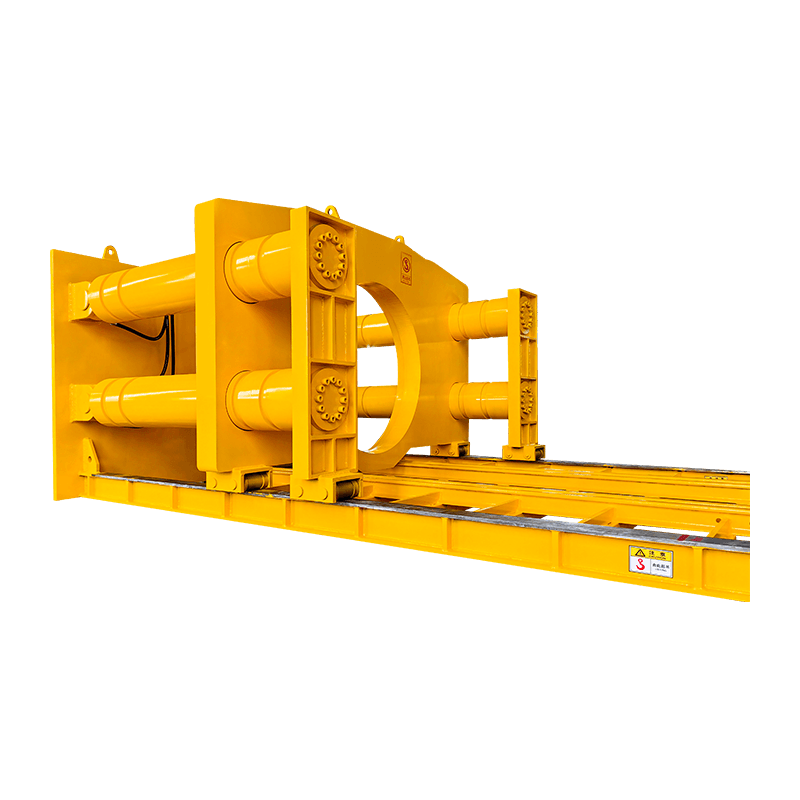

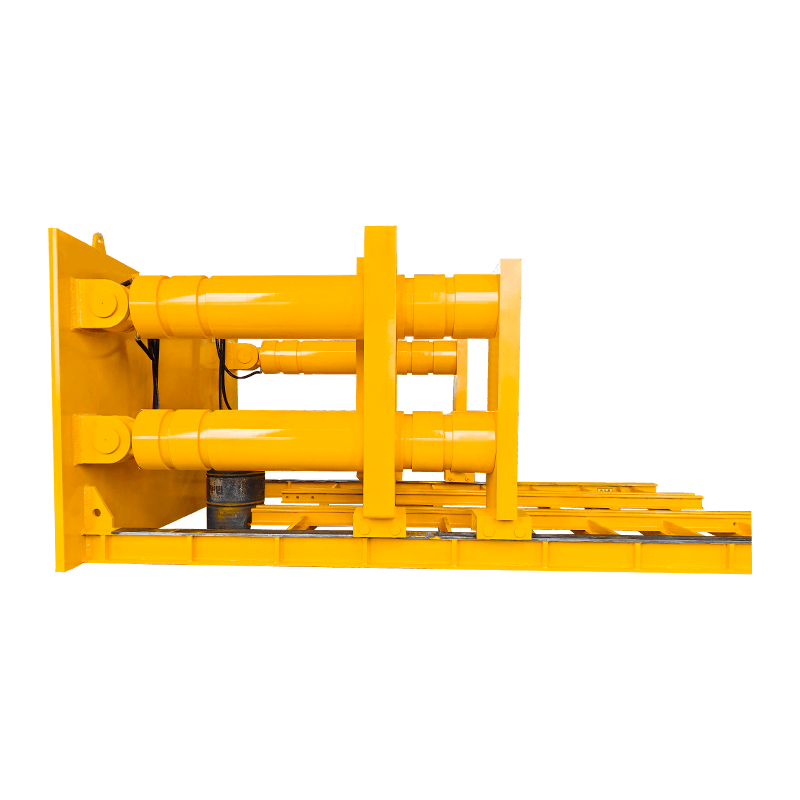

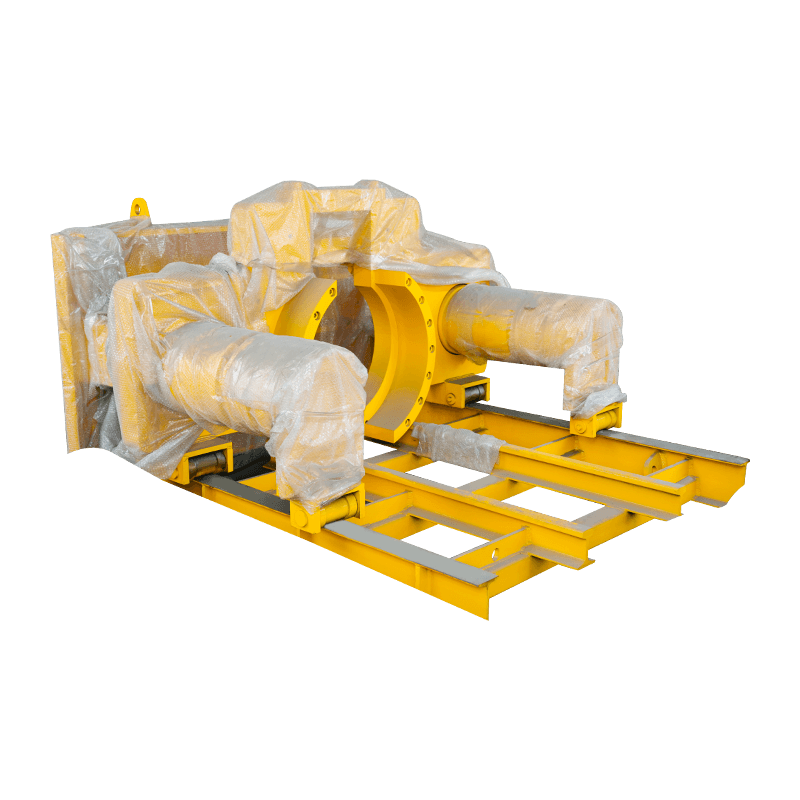

- Hydraulic Thrust System: A series of high-capacity cylinders that propel the shield forward by pushing against the last installed segment ring.

- Screw Conveyor: In EPB machines, this regulates the volume of soil removed to maintain steady pressure at the excavation face.

- Grout Injection Ports: These fill the "annulus" or the small gap between the concrete segments and the raw earth to prevent surface sinking.

Environmental and Safety Advantages of TBM Technology

One of the primary reasons for the dominance of tunnel machines in modern civil engineering is their ability to operate without disrupting the surface environment. In urban centers, TBMs allow for the construction of subway lines and sewage systems directly beneath active skyscrapers and historical landmarks. Because the excavation happens within a sealed shield, the risk of groundwater contamination or gas leaks into the atmosphere is significantly reduced. Furthermore, the automated nature of the machine keeps workers inside a reinforced steel structure, protecting them from the dangers of cave-ins or falling rock that were common in traditional mining.

Future Trends in Tunneling: Automation and Micro-Tunneling

The industry is currently pivoting toward fully autonomous tunnel boring systems. These next-generation machines use artificial intelligence to analyze soil density and moisture content in real-time, automatically adjusting the rotation speed and thrust to optimize energy consumption and cutter longevity. Additionally, "micro-tunneling" has become a vital sub-sector, utilizing smaller, remote-controlled TBMs for the installation of utility pipes. These smaller units allow for "trenchless" technology, meaning cities can upgrade their water and fiber-optic networks without digging up miles of roadway, drastically reducing the economic impact of infrastructure maintenance.

As global populations continue to densify, the reliance on subterranean space will only grow. The evolution of the tunnel machine from a simple drill to a high-tech robotic system ensures that we can continue to expand our transportation, energy, and water networks safely and sustainably beneath the earth's surface.

English

English  русский

русский  عربى

عربى