Understanding TBM Manufacturing and Its Importance

Tunnel Boring Machines (TBMs) have revolutionized the construction of underground infrastructures, from metro lines to utility tunnels. The manufacturing of TBMs requires precision engineering and the integration of multiple complex systems, including cutting heads, conveyor systems, and hydraulic mechanisms. High-quality manufacturing ensures the TBM operates efficiently in challenging geological conditions while minimizing downtime and maintenance costs.

Modern TBM manufacturing combines mechanical engineering, electrical systems, and software controls to create machines capable of precise tunneling in urban and remote environments. Manufacturers must pay attention to material selection, design optimization, and the integration of automation systems to improve productivity and safety.

Core Components in TBM Manufacturing

The effectiveness of a TBM depends heavily on the quality and design of its core components. Key elements include:

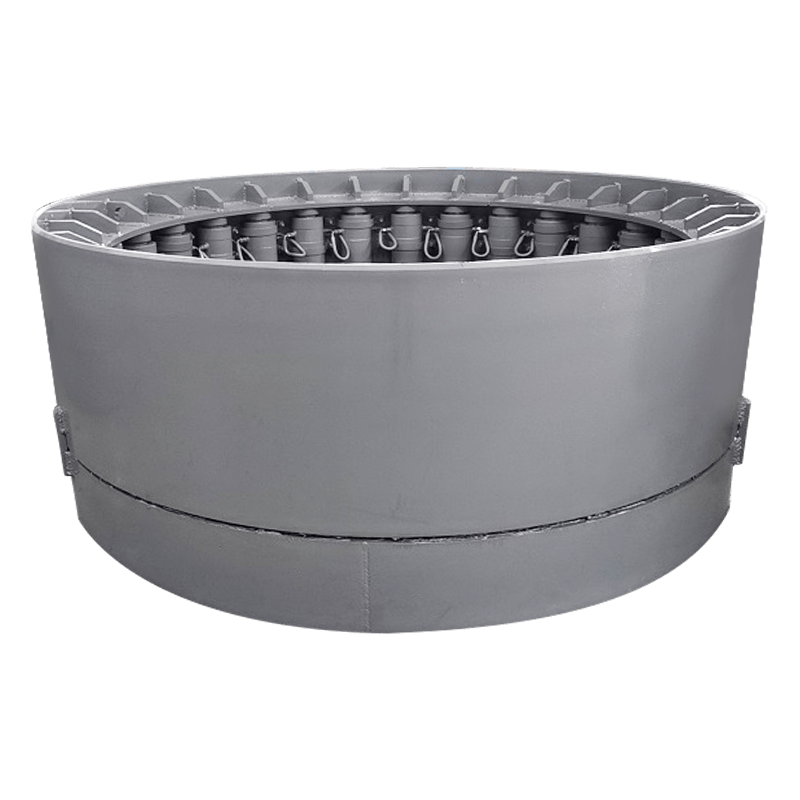

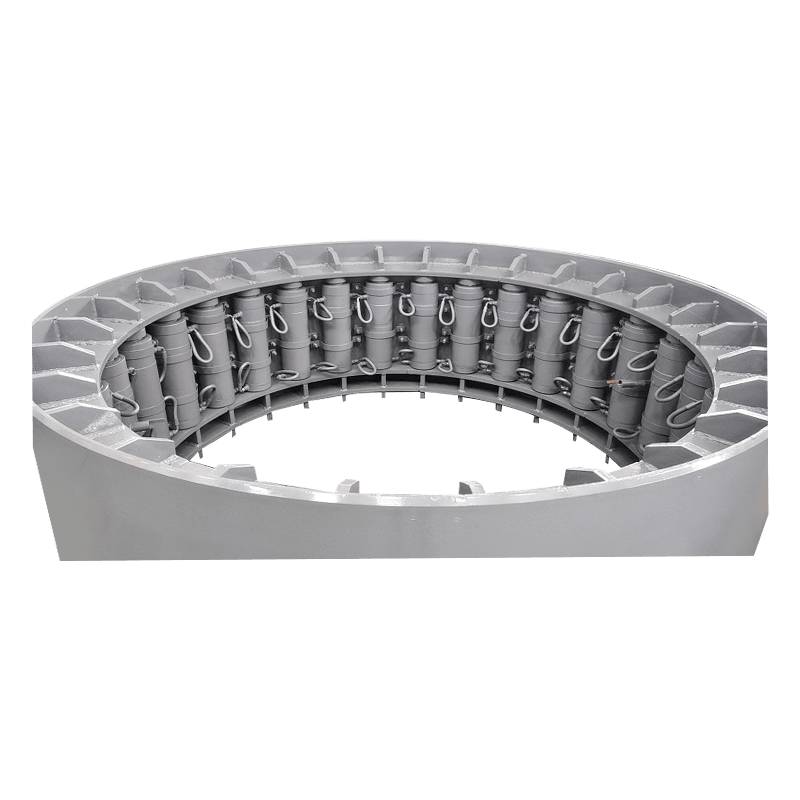

- Cutter Head: The front-end component that breaks the soil or rock. Precision manufacturing ensures optimal rotation and minimal wear.

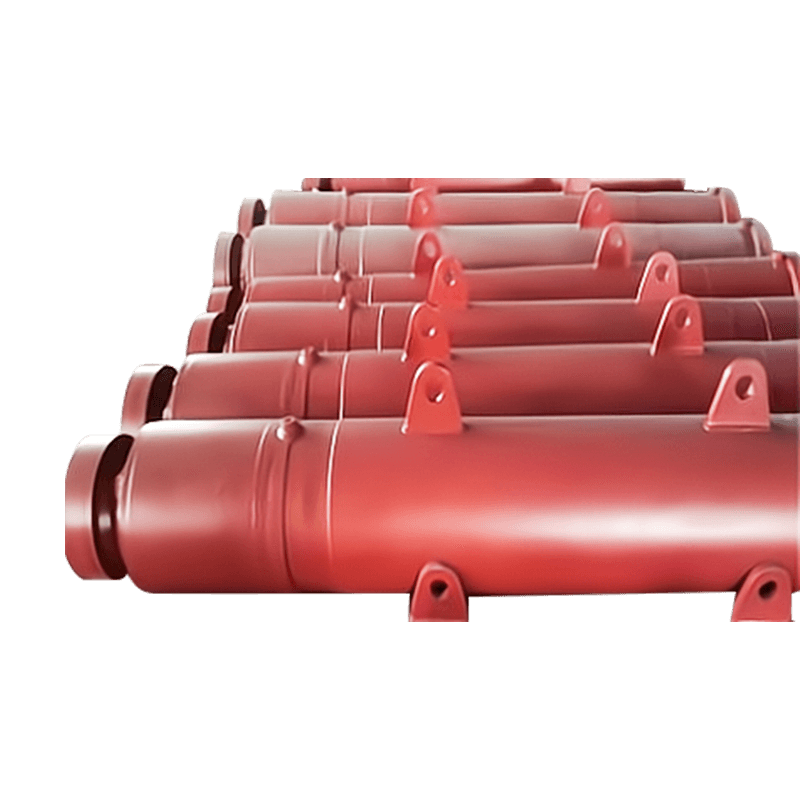

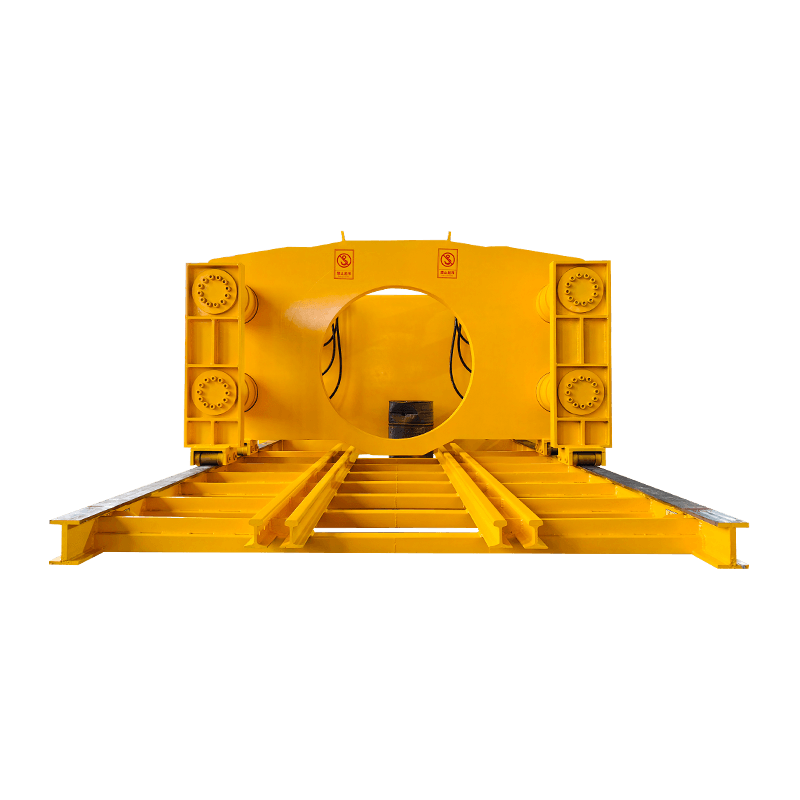

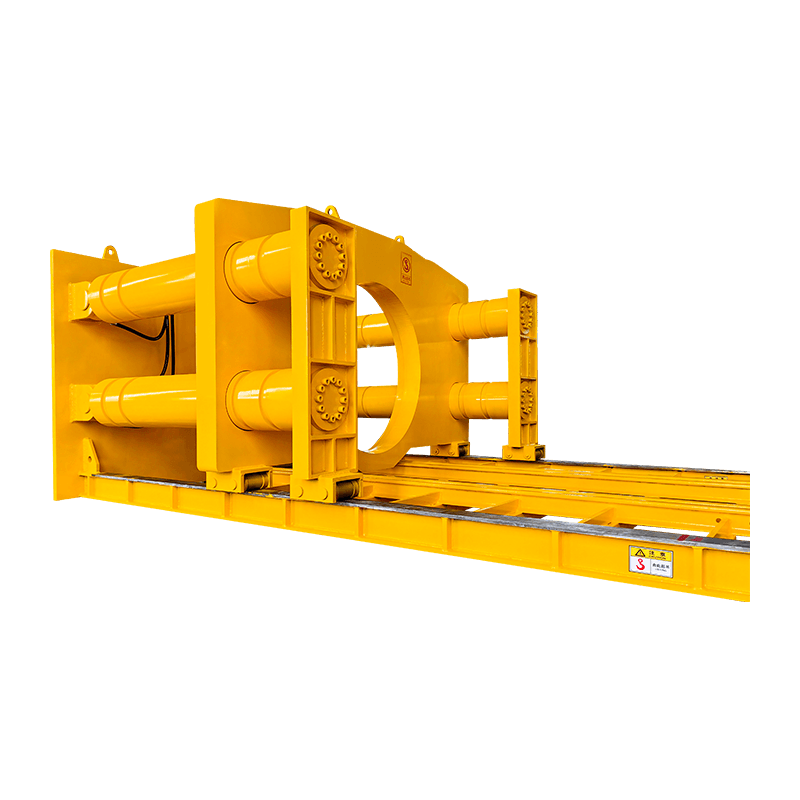

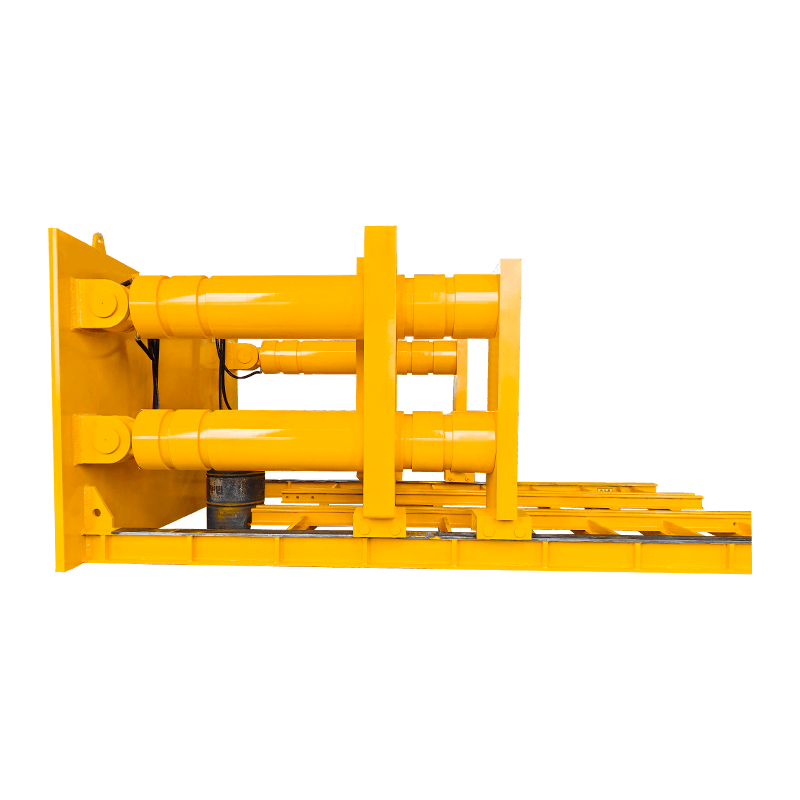

- Thrust System: Hydraulic cylinders that push the TBM forward. Accurate manufacturing ensures even force distribution to prevent alignment issues.

- Conveyor System: Removes excavated material efficiently. Manufactured with durable components to withstand abrasive conditions.

- Shield and Cutter Support: Protects the machine and workers during tunneling. Requires high-strength steel and precise assembly.

- Guidance and Control Systems: Advanced electronics and sensors ensure precise navigation and tunneling accuracy.

Materials and Precision Engineering in TBM Production

Materials used in TBM manufacturing must balance strength, durability, and weight. High-strength steel alloys are commonly used for cutting heads and shields, while wear-resistant materials are applied to critical components to extend operational life. Precision engineering ensures components are manufactured to tight tolerances, reducing vibration and improving machine stability.

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies are integral to modern TBM production. They allow engineers to simulate geological interactions, optimize cutter head design, and streamline assembly processes, resulting in faster production times and improved machine reliability.

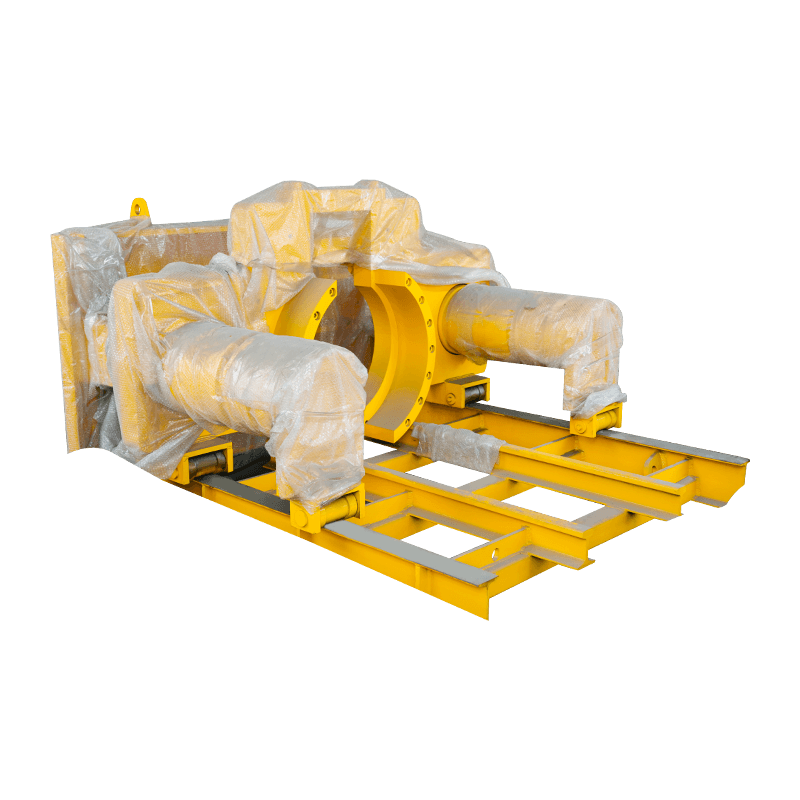

Quality Control and Testing Procedures

Stringent quality control is essential in TBM manufacturing to ensure reliability in challenging tunneling conditions. Common testing procedures include:

- Mechanical load testing of hydraulic systems.

- Wear resistance testing for cutting tools and conveyor components.

- Alignment and calibration checks for guidance systems.

- Operational simulation in controlled environments before deployment.

These tests not only validate design specifications but also help identify potential issues that could lead to downtime or costly repairs in the field.

Emerging Innovations in TBM Manufacturing

The TBM industry is experiencing significant innovations to improve efficiency and reduce operational costs. Notable advancements include:

- Automated monitoring systems that use real-time data for predictive maintenance.

- Hybrid cutter heads capable of handling mixed ground conditions without changing tools.

- Lightweight composite materials that reduce energy consumption during tunneling.

- Advanced lubrication and cooling systems that extend the lifespan of critical components.

Comparing TBM Manufacturing Standards Worldwide

TBM manufacturing standards vary across regions depending on geological conditions, safety regulations, and technological adoption. The following table highlights key aspects:

| Region | Material Standards | Automation Level | Average Production Time |

| Europe | High-strength alloys, wear-resistant steel | High | 12-18 months |

| Asia | Alloys with local adaptation, composite materials | Medium to High | 10-16 months |

| North America | Premium steel and advanced sensors | High | 14-20 months |

Conclusion: The Future of TBM Manufacturing

TBM manufacturing is at the forefront of underground construction innovation. As urbanization and infrastructure demands grow, manufacturers are focusing on efficiency, reliability, and smart technologies. By combining precision engineering, high-quality materials, and advanced automation, the next generation of TBMs will offer faster, safer, and more cost-effective tunneling solutions worldwide.

English

English  русский

русский  عربى

عربى