The Tunneling Boring Machine (TBM), often referred to simply as a “mole,” represents one of the most significant advancements in civil and geotechnical engineering. These massive, sophisticated machines have revolutionized the construction of underground infrastructure, enabling the creation of tunnels for transportation, utilities, and mining with unprecedented speed, precision, and safety.

Mechanism and Core Components

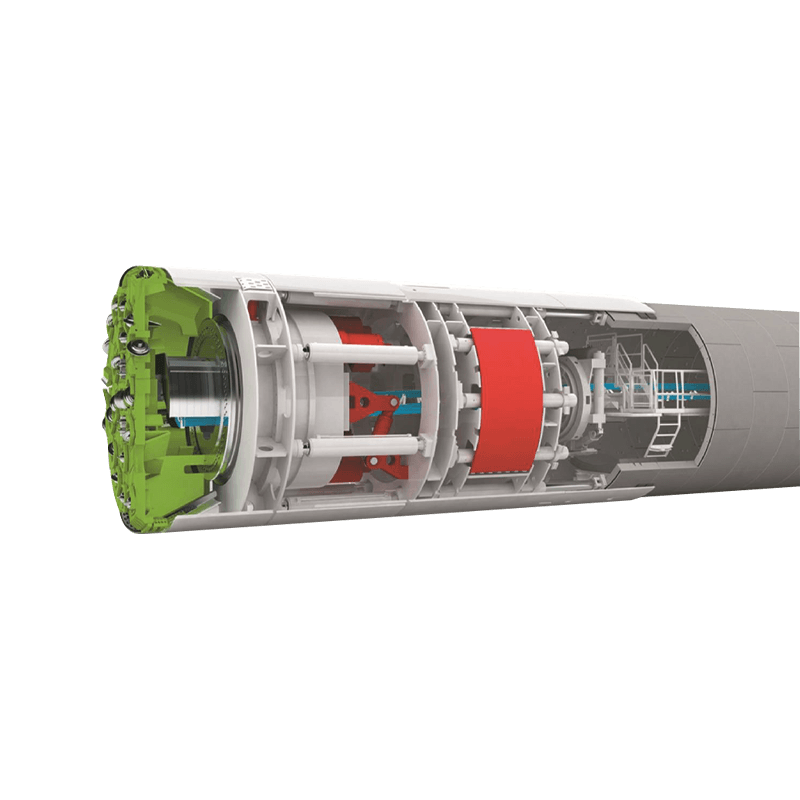

A Tunneling Boring Machine is essentially a complete mobile factory designed to excavate a tunnel face and simultaneously install a temporary or permanent support system. A TBM generally consists of three primary sections:

-

Cutter Head (The Face):

- This is the front-most, rotating element, equipped with various cutting tools—such as disc cutters for hard rock or a combination of cutter bits and drag picks for softer ground.

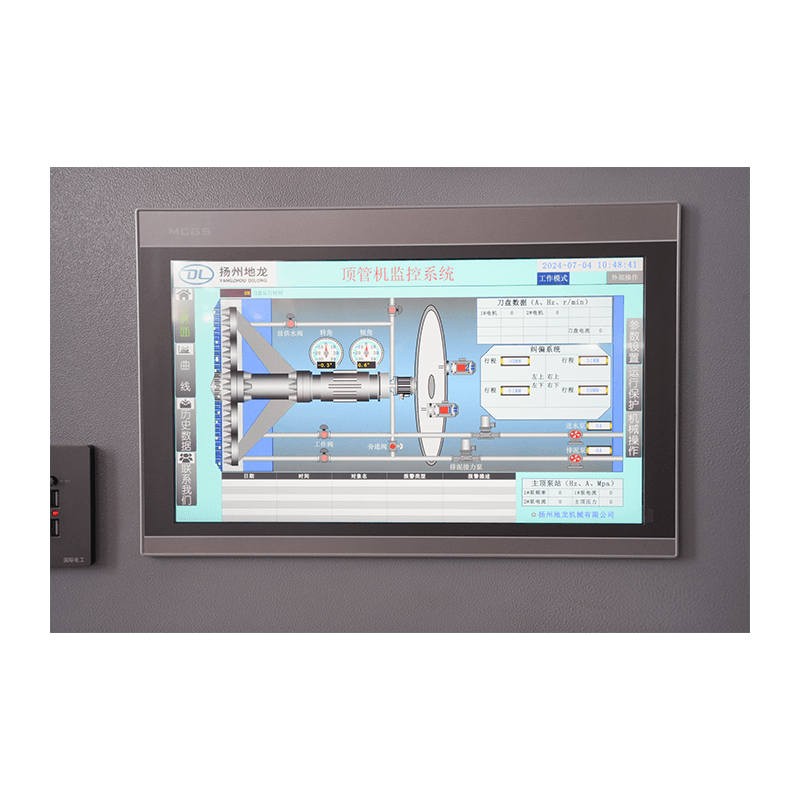

- The cutter head rotates and is thrust forward by hydraulic jacks, crushing or scraping the rock and soil at the tunnel face.

-

Shield and Body (The Middle):

- The shield is a large, cylindrical steel casing directly behind the cutter head. It provides immediate structural support to the freshly excavated tunnel walls, protecting the machine and the workers inside from loose ground until the permanent tunnel lining is installed.

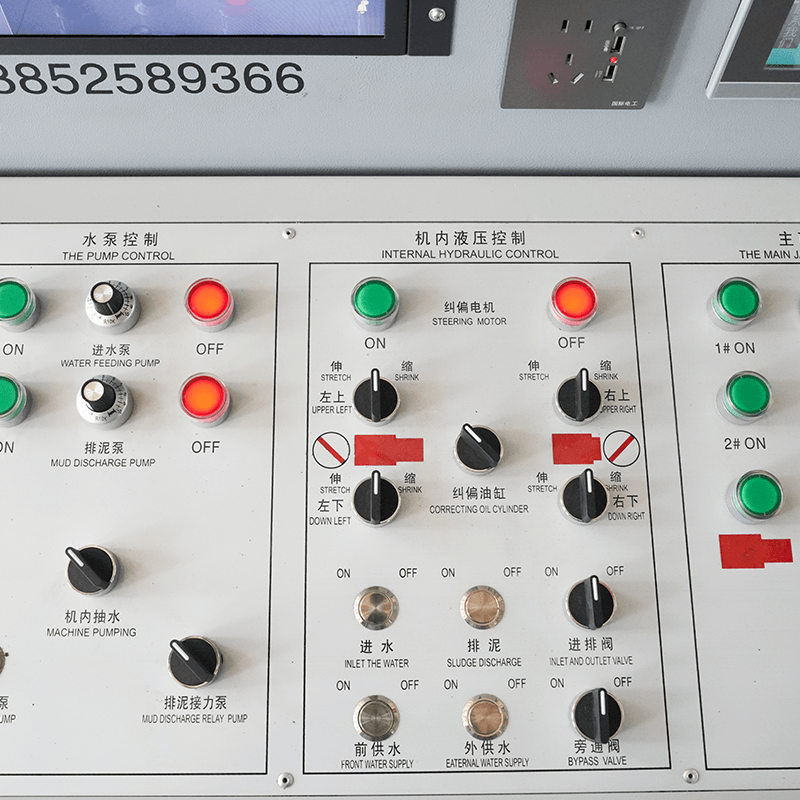

- The thrust system, composed of powerful hydraulic jacks, presses against the last installed tunnel lining segment to advance the machine.

-

Trailing Gear (The Rear):

- This section, which can stretch over a hundred meters in length, houses the essential support equipment.

- It includes the muck removal system (conveyor belts or slurry pipes) to efficiently transport the excavated material (“muck”) out of the tunnel, control and power systems, ventilation equipment, and the crucial segment erector which precisely places the precast concrete segments that form the permanent tunnel lining.

Classification and Types of TBMs

TBM selection is a critical decision in any project, depending heavily on the specific geological conditions and groundwater pressure. TBMs are broadly categorized based on the ground they are designed to bore through:

1. Hard Rock TBMs

- Open-Type / Gripper TBMs: Used in stable, hard rock conditions that can support themselves for a short period without immediate lining. They use hydraulic grippers to anchor against the tunnel walls, which allows the machine to react the forward thrust of the cutter head.

- Single Shield TBMs: Employed in fractured or less stable hard rock. They install the concrete lining segments directly behind the shield and thrust forward by pushing off the completed lining.

- Double Shield TBMs: The most versatile hard rock machines. They feature two telescoping shields and a gripping system, allowing them to install the lining simultaneously while excavating (continuous tunneling) when in stable rock, or operate in alternating modes when conditions are unstable.

2. Soft Ground TBMs (Shield Machines)

These machines incorporate methods to actively balance the pressure at the tunnel face, crucial for preventing ground collapse or water ingress in soft soils (like sand, clay, and silt).

- Earth Pressure Balance (EPB) TBMs: Ideal for cohesive, soft ground. They maintain stability by using the excavated material (muck) within a pressurized chamber at the cutter face. A screw conveyor controls the rate of muck removal to precisely balance the earth and water pressure ahead of the machine.

- Slurry Shield TBMs (Hydroshield): Used in granular soils or under high water pressure. They stabilize the face by injecting a pressurized bentonite slurry, which forms a filter cake to seal the ground. The excavated material is mixed with the slurry and pumped out to a separation plant on the surface.

Advantages Over Conventional Methods

The global adoption of the Tunneling Boring Machine is driven by several significant benefits compared to the traditional “drill-and-blast” method:

- Enhanced Safety: Eliminates the use of explosives, drastically reducing risks to personnel.

- Minimal Surface Disruption: Operations are primarily underground, minimizing noise, vibration, and disruption—a major advantage in urban areas.

- Increased Speed and Efficiency: TBMs provide a continuous tunneling process, often achieving significantly higher advance rates than drill-and-blast.

- Precision: Modern TBMs are guided by sophisticated laser or navigation systems, ensuring high alignment accuracy.

- Reduced Over-excavation: The TBM bores a precise circular tunnel, reducing the amount of spoil (muck) generated and the volume of lining material required.

In conclusion, the Tunneling Boring Machine is an indispensable tool for 21st-century infrastructure development. As urban populations grow and the need for complex, long-distance infrastructure like high-speed rail tunnels and vast utility networks increases, the role of the TBM as an engineering marvel will only become more vital.

English

English  русский

русский  عربى

عربى