The Auger Boring Machine (ABM) is a specialized piece of construction equipment indispensable for creating horizontal bores beneath the ground surface. This trenchless technology is crucial for installing utilities like pipelines, conduits, and cables without disrupting existing infrastructure, traffic flow, or surface landscapes. Its ability to bore accurately over short to medium distances makes it a cornerstone of modern civil engineering and infrastructure development.

How the Auger Boring Machine Works

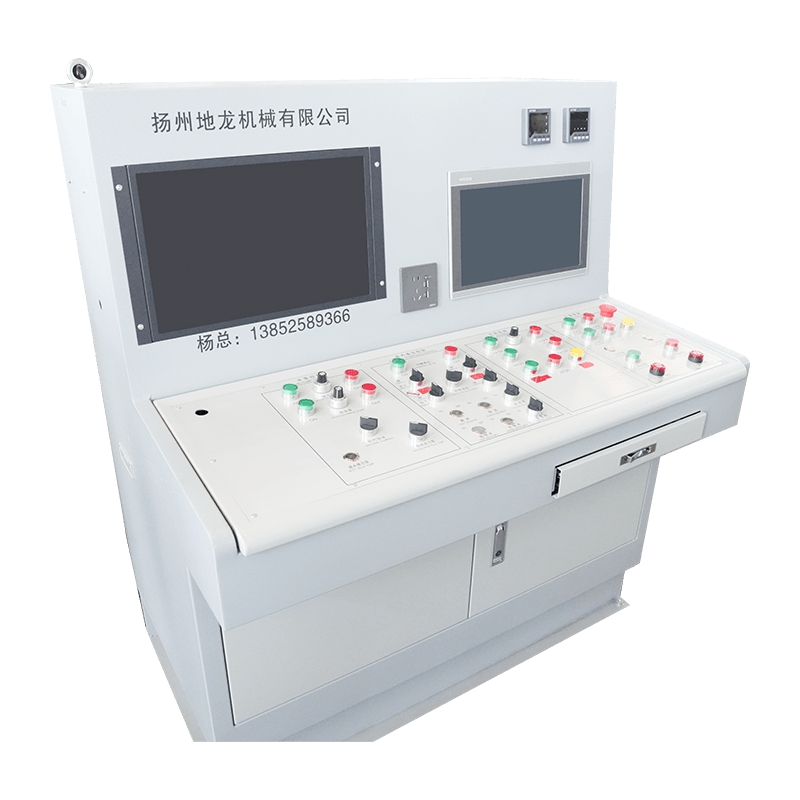

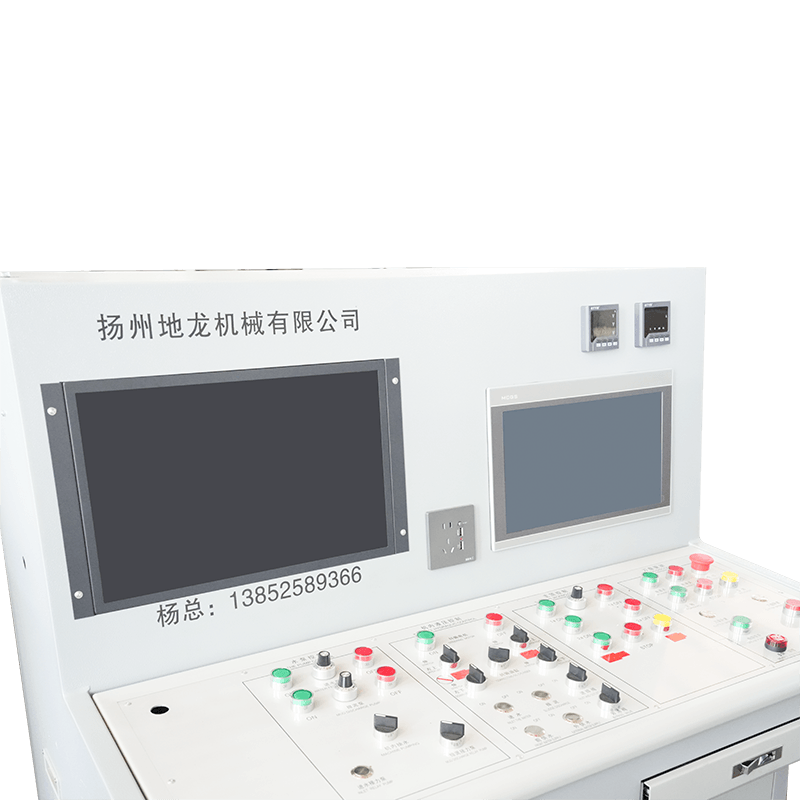

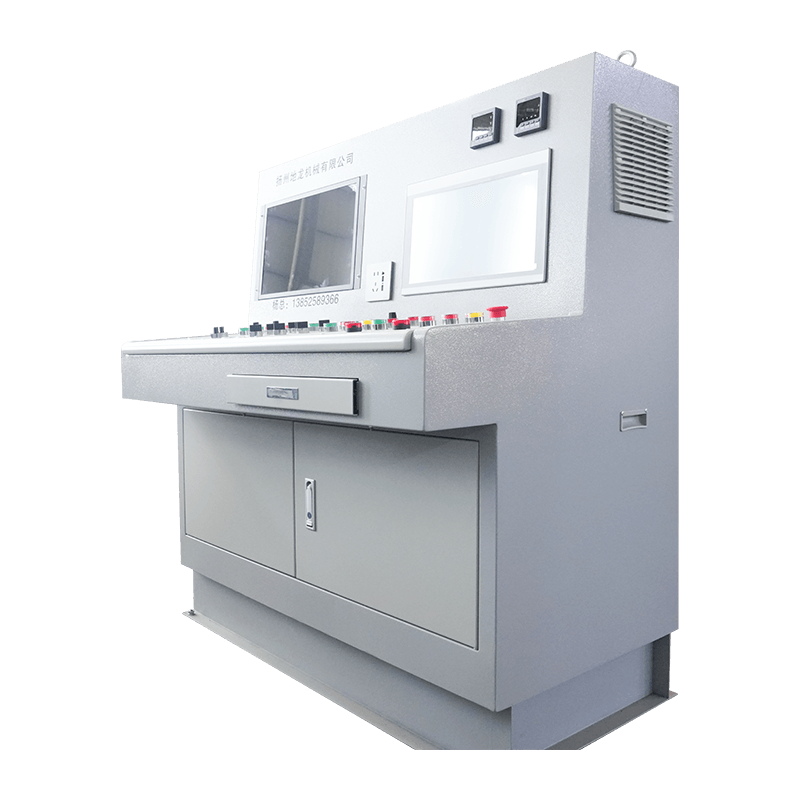

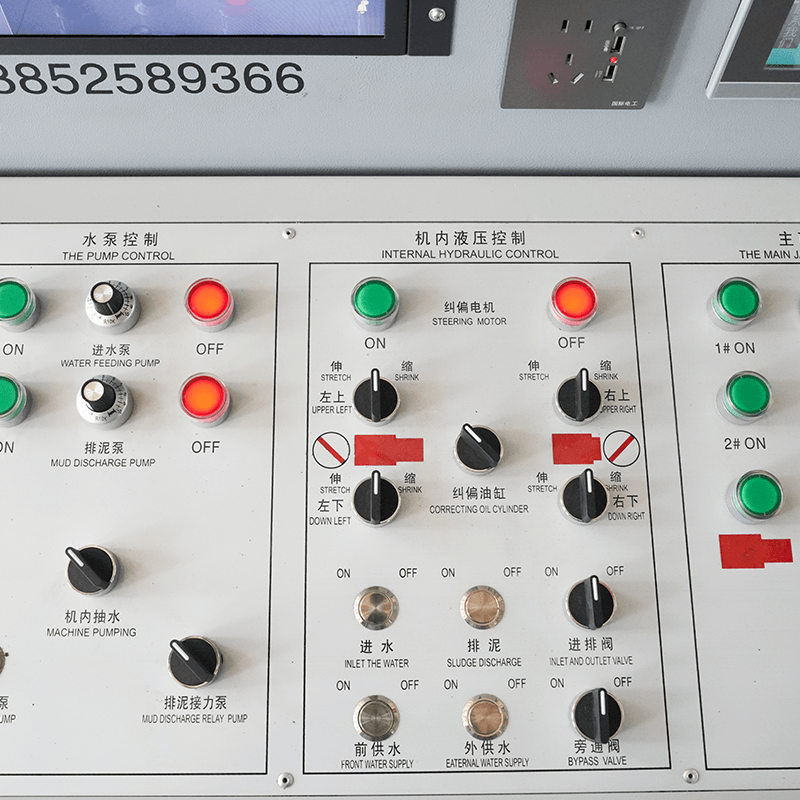

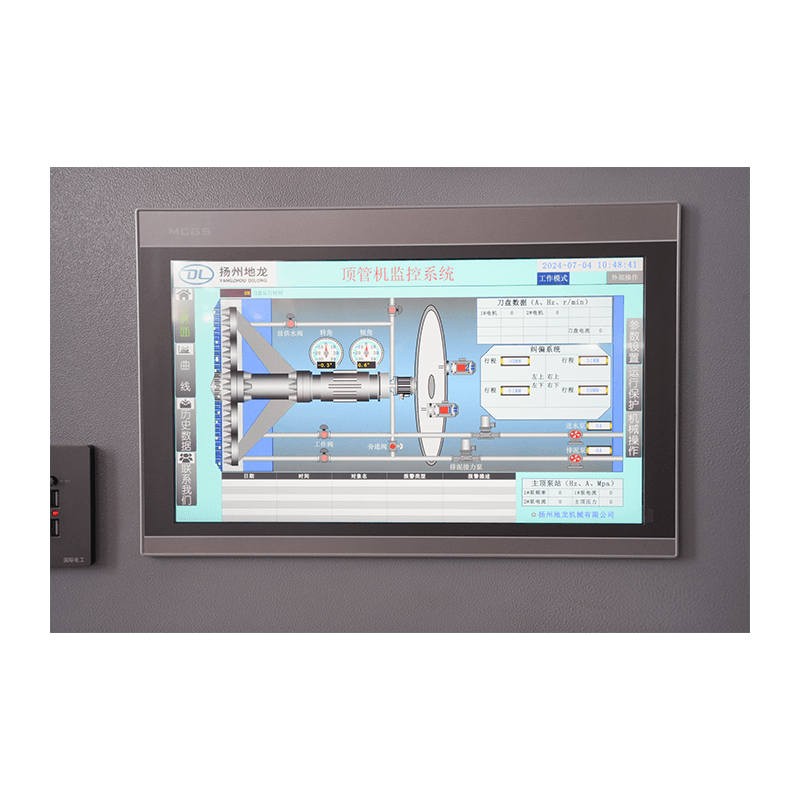

At its core, the Auger Boring Machine employs a rotational cutting head, or face, to excavate the soil or rock. This cutting head is connected to a series of auger flights—long, helical screws—that transport the excavated material (spoil) back to the launch pit. The entire process is driven by a powerful thrust and torque system housed within the machine’s body.

Key Components and the Boring Process

- Launch Pit: The process begins with the excavation of a launch pit and a reception pit, which define the start and end points of the bore.

- Casing Pipe: The ABM pushes a steel casing pipe into the ground simultaneously with the boring action. This pipe provides structural stability to the bore and acts as the final conduit for the utility.

- Auger Flights: As the cutting head advances, the rotating auger flights within the casing pipe scoop and convey the spoil out of the borehole.

- Steering: While traditional Auger Boring Machines offer limited steering, modern systems sometimes incorporate line and grade adjustments, particularly for longer or more critical bores, though they are generally less flexible than true guided boring systems.

This concurrent excavation and casing installation are what define the efficiency and reliability of the Auger Boring Machine.

Applications in Infrastructure

The versatility of the Auger Boring Machine makes it suitable for a wide array of underground construction projects:

- Utility Crossings: It’s frequently used to install water, sewer, gas, and telecommunication lines beneath roads, highways, railways, and airport runways where open-cut trenching is impractical or prohibited.

- Environmental Sensitivity: In environmentally sensitive areas, such as wetlands or protected natural habitats, the ABM minimizes surface disturbance, preserving the ecosystem above the bore path.

- Structural Integrity: By installing the strong steel casing, the Auger Boring Machine ensures the long-term protection of the installed utility from external loads and ground movement.

Advantages Over Traditional Methods

The adoption of the Auger Boring Machine is driven by significant advantages over conventional open-cut methods:

| Feature | Auger Boring Machine (Trenchless) | Open-Cut Trenching (Traditional) |

|---|---|---|

| Surface Disruption | Minimal; restricted to the launch and reception pits. | Significant; requires excavation along the entire path. |

| Traffic Impact | Negligible, as work is confined underground. | High; often requires road closures and detours. |

| Cost Efficiency | Often lower for deep or long crossings under paved areas. | High labor and restoration costs. |

| Speed | Can complete crossings relatively quickly once set up. | Slowed by utility conflicts and surface restoration requirements. |

| Accuracy | Good control over line and grade, especially in stable soils. | Accuracy dependent on the ground stability and trench shoring. |

The robust design of the Auger Boring Machine allows it to operate effectively in varying soil conditions, from soft clays and sands to hard rock, often requiring interchangeable cutting heads tailored to the specific geology. This adaptability ensures project feasibility even in challenging ground.

The Future of Auger Boring

As urban density increases and the demand for robust, resilient infrastructure grows, the importance of the Auger Boring Machine will only escalate. Innovations in guidance systems, monitoring technology, and cutting tools are continually enhancing the precision and capability of ABMs. The development of larger, more powerful machines capable of handling longer bores and harder rock formations is pushing the boundaries of what this proven trenchless technology can achieve. Ultimately, the Auger Boring Machine remains a critical tool for sustainable, efficient, and non-disruptive infrastructure development worldwide.

English

English  русский

русский  عربى

عربى