Core Technologies in Modern Pipe Cutting and Threading

The modern pipe machine has evolved from simple manual tools to highly sophisticated CNC-controlled systems capable of extreme precision. At the heart of industrial fabrication is the pipe threading machine, which utilizes high-speed steel (HSS) dies to create tapered or straight threads on various metallic conduits. These machines are designed to handle heavy-duty loads while maintaining the integrity of the pipe's structural wall. Advanced models now incorporate automatic oiling systems that lubricate the dies during the cutting process, significantly extending the lifespan of the tooling and ensuring a smoother finish on the threads.

Beyond threading, high-performance pipe cutting machines utilize cold cutting technology. Unlike traditional abrasive saws, these machines use a rotating blade or a high-torque motor to slice through thick-walled pipes without generating a Heat Affected Zone (HAZ). This is critical in industries like oil and gas or pharmaceutical manufacturing, where the metallurgical properties of the pipe must remain unchanged to prevent future corrosion or structural failure at the joints.

Automated Pipe Bending and Formwork

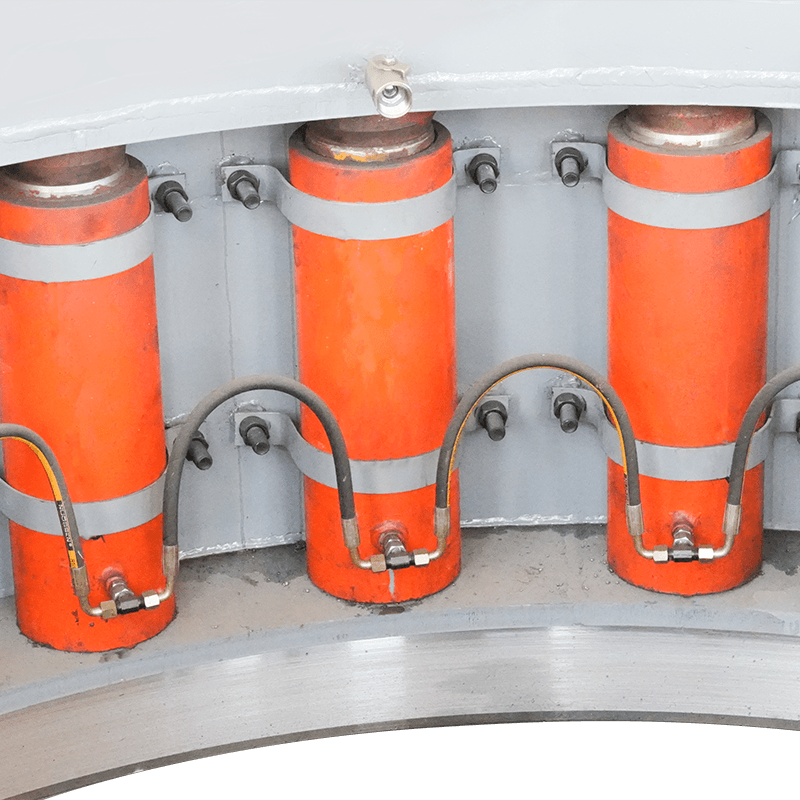

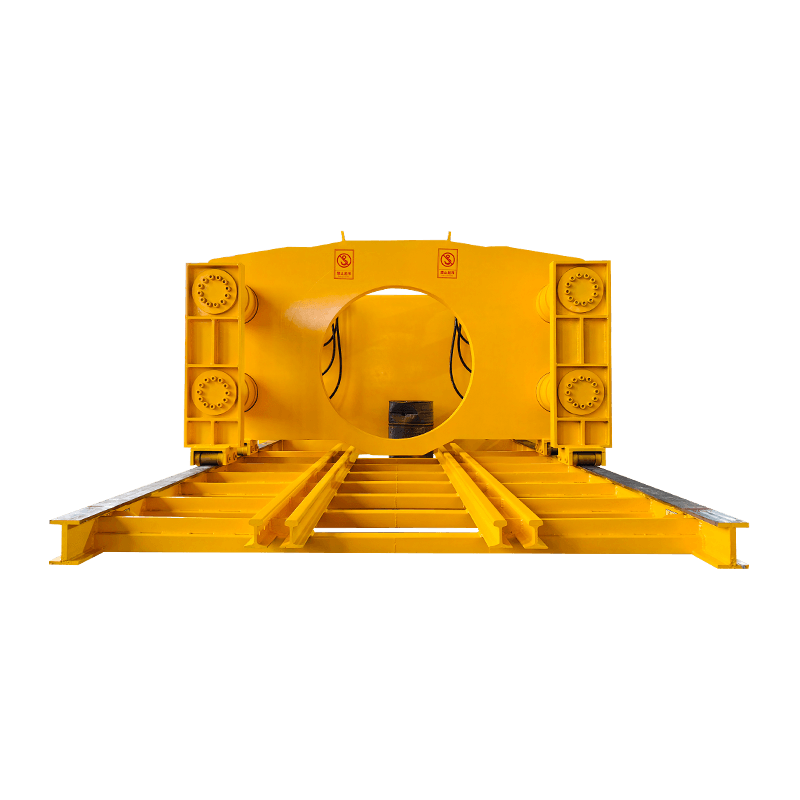

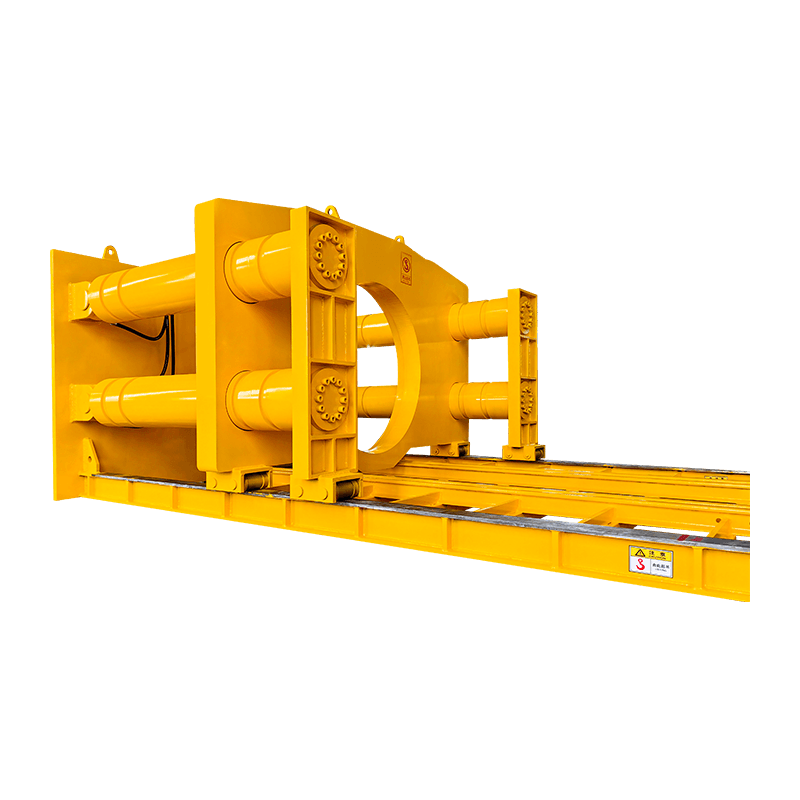

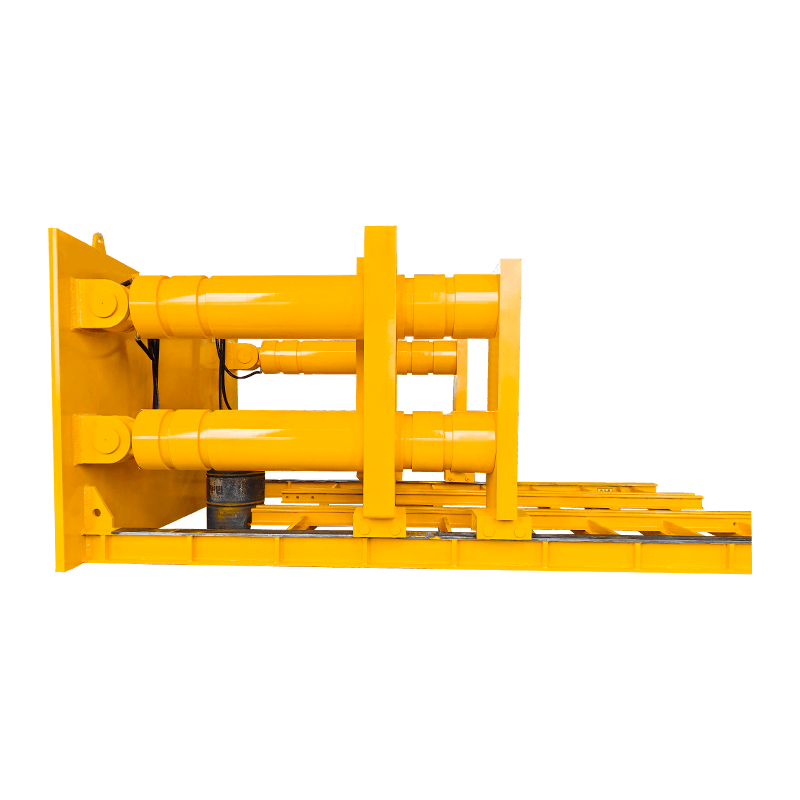

Pipe bending machines are essential for creating seamless transitions in fluid transport systems without the need for excessive elbows or welds. Mandrel benders are particularly valued for their ability to prevent the pipe from collapsing or wrinkling during the bending process. By inserting a solid rod (the mandrel) into the pipe, the machine supports the internal diameter, allowing for tight-radius bends that maintain consistent flow rates and pressure levels throughout the system.

Key Components of a Pipe Bending System

- Bend Die: The primary tool that determines the radius of the bend.

- Pressure Die: Applies the necessary force to push the pipe against the bend die.

- Clamp Die: Securely holds the pipe in place to prevent slippage during the rotation.

- Wiper Die: Prevents wrinkling on the inside of the bend for thin-walled materials.

Technical Comparison of Pipe Machine Categories

Selecting the right machinery depends heavily on the volume of production and the specific material being processed. Portable machines offer flexibility for on-site repairs, while stationary industrial workstations provide the power needed for high-volume manufacturing. The table below outlines the primary differences between common pipe processing technologies used in the field today.

| Machine Type | Primary Function | Optimal Materials | Precision Level |

| CNC Pipe Threader | Automated Threading | Steel, Stainless, Galvanized | High (Digital Control) |

| Orbital Pipe Cutter | Squaring and Cutting | Thin-walled Tubing, Alloys | Ultra-High (Burr-free) |

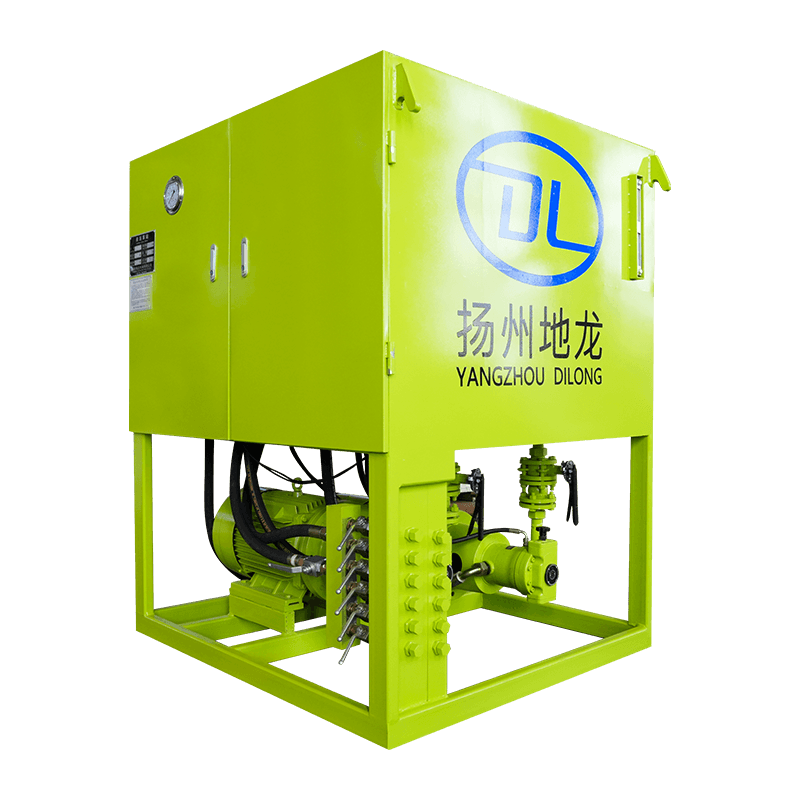

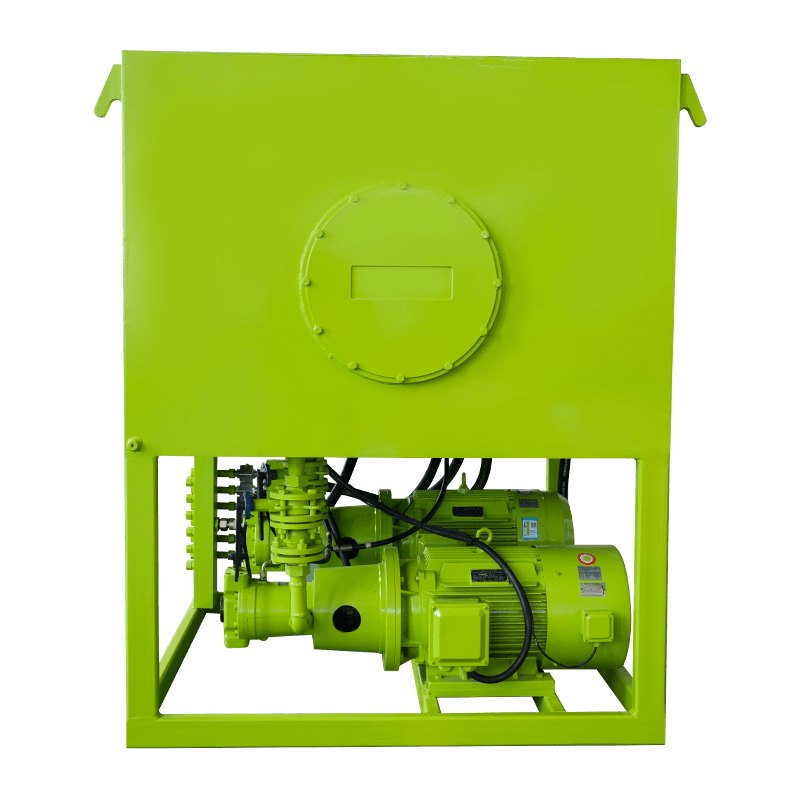

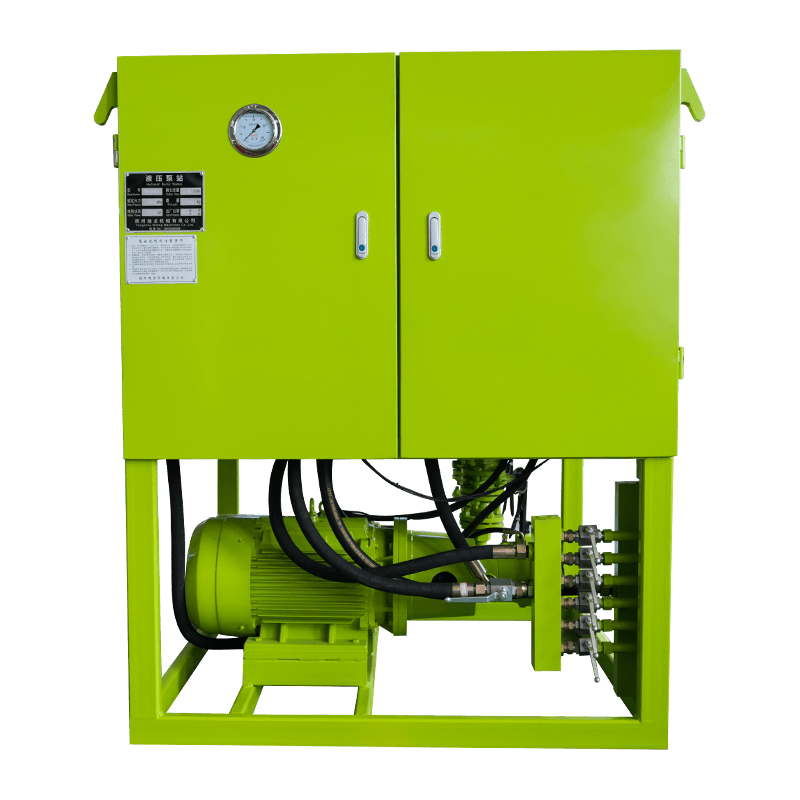

| Hydraulic Pipe Bender | Curvature Shaping | Copper, Carbon Steel, Aluminum | Medium to High |

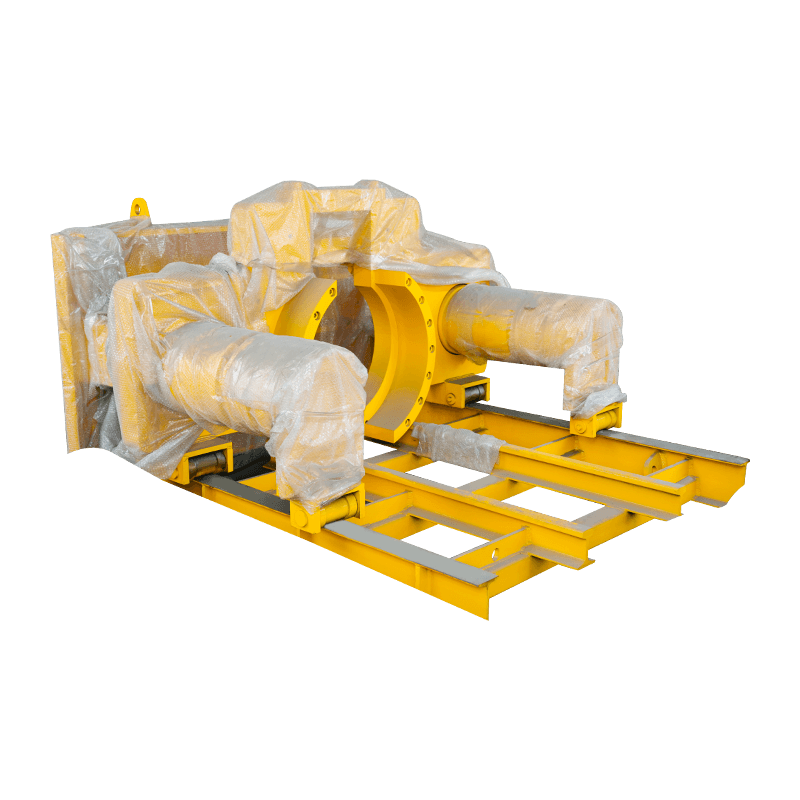

Maintenance Protocols for Longevity and Safety

Regular maintenance of pipe machinery is non-negotiable for ensuring operator safety and maintaining tight tolerances. Metal shavings and debris are the primary enemies of these machines; if left uncleaned, they can clog lubrication lines and scar the precision surfaces of the dies. Operators should perform daily checks on the hydraulic fluid levels and inspect the cutting edges of dies and blades for signs of dulling or chipping. Dull tools require more torque, which can lead to motor burnout and uneven threading.

Calibration is another vital aspect of machine upkeep. Over time, the vibration from heavy-duty cutting can cause sensors and alignment guides to shift. Quarterly calibration ensures that the machine continues to meet ISO standards and that every pipe produced fits perfectly into the larger infrastructure project. Implementing a rigorous maintenance schedule not only prevents downtime but also ensures that the final product meets the safety requirements for high-pressure applications.

English

English  русский

русский  عربى

عربى