The Anatomy and Engineering of Tunnel Boring Machines

A Tunnel Boring Machine (TBM), often referred to as a "mechanical mole," is a sophisticated piece of heavy equipment designed to excavate tunnels with a circular cross-section through various soil and rock strata. Unlike traditional drill-and-blast methods, TBMs offer the advantage of limiting the disturbance to the surrounding ground and producing a smooth tunnel wall. The machine consists of a rotating cutting head that breaks up the face of the rock or soil, a thrust system to push the machine forward, and a trailing gear that facilitates muck removal and the installation of permanent tunnel linings.

Core Components of a TBM

- Cutterhead: The front-facing disc equipped with tungsten carbide cutters or disc cutters designed to grind through geological formations.

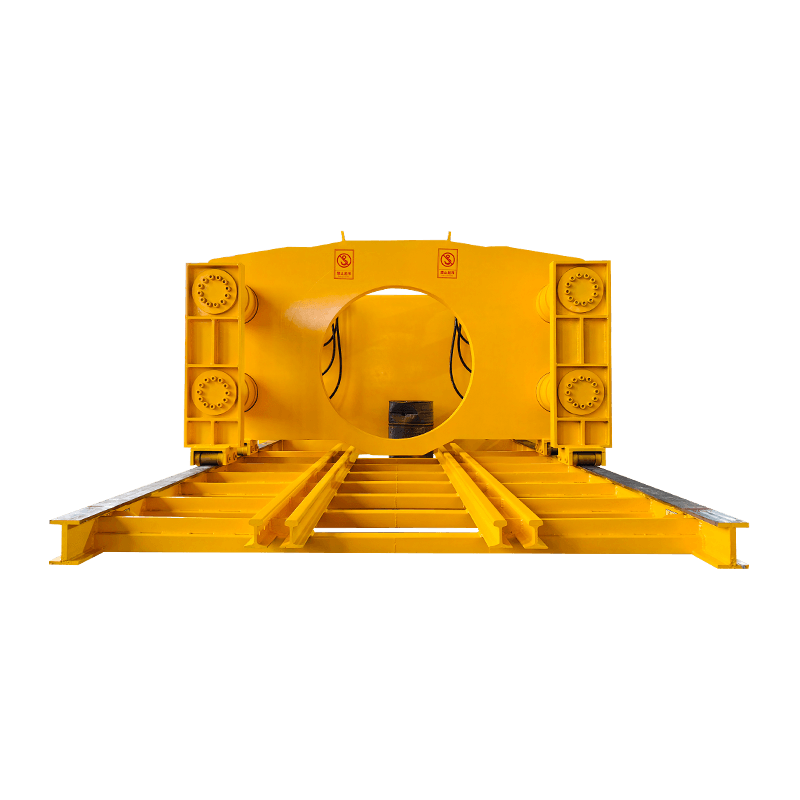

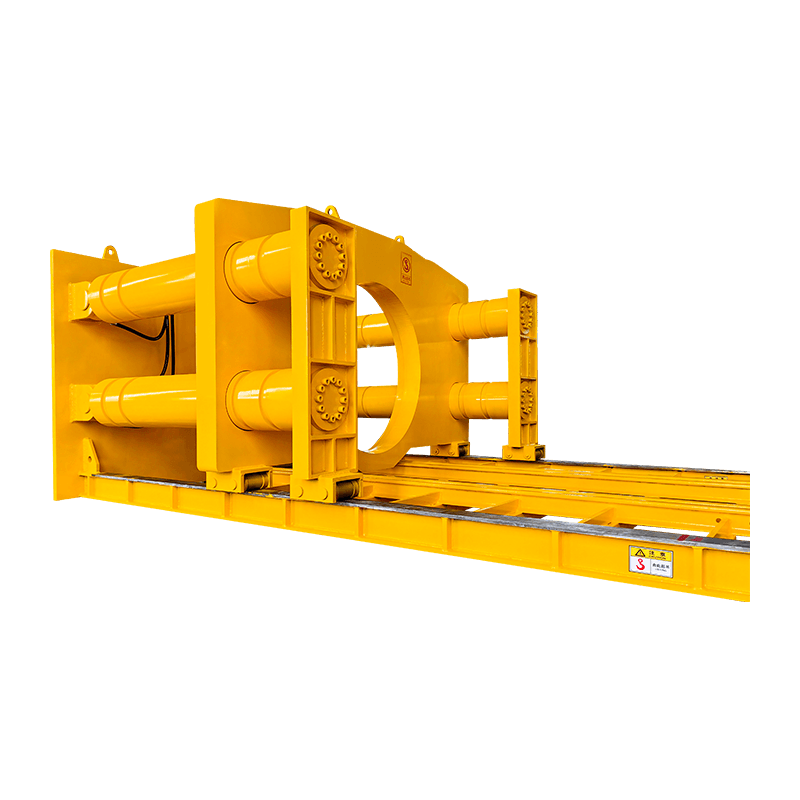

- Shield: A protective steel cylinder that prevents the surrounding earth from collapsing into the machine while the tunnel lining is being installed.

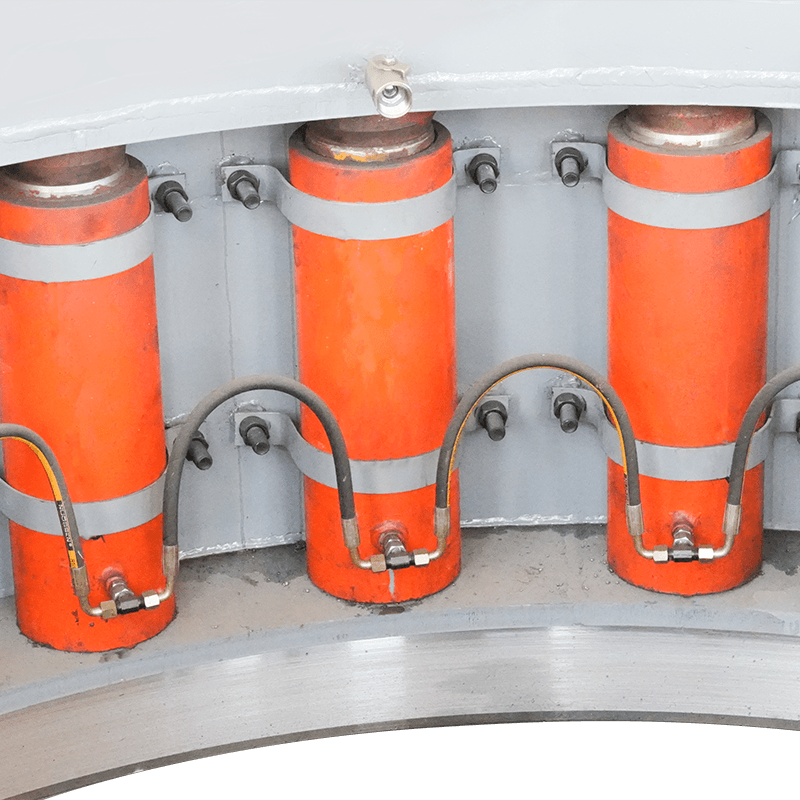

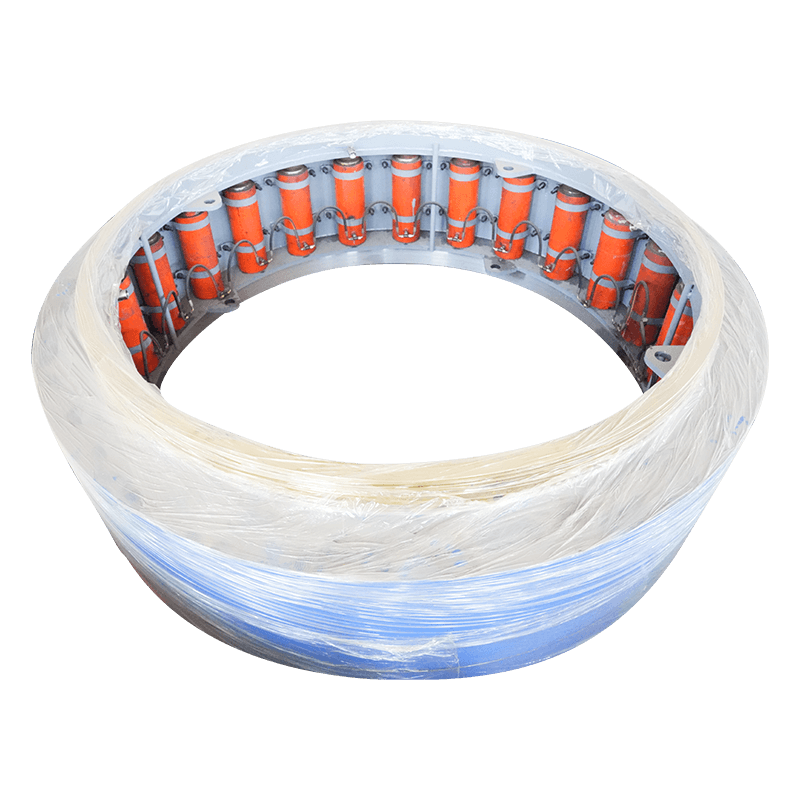

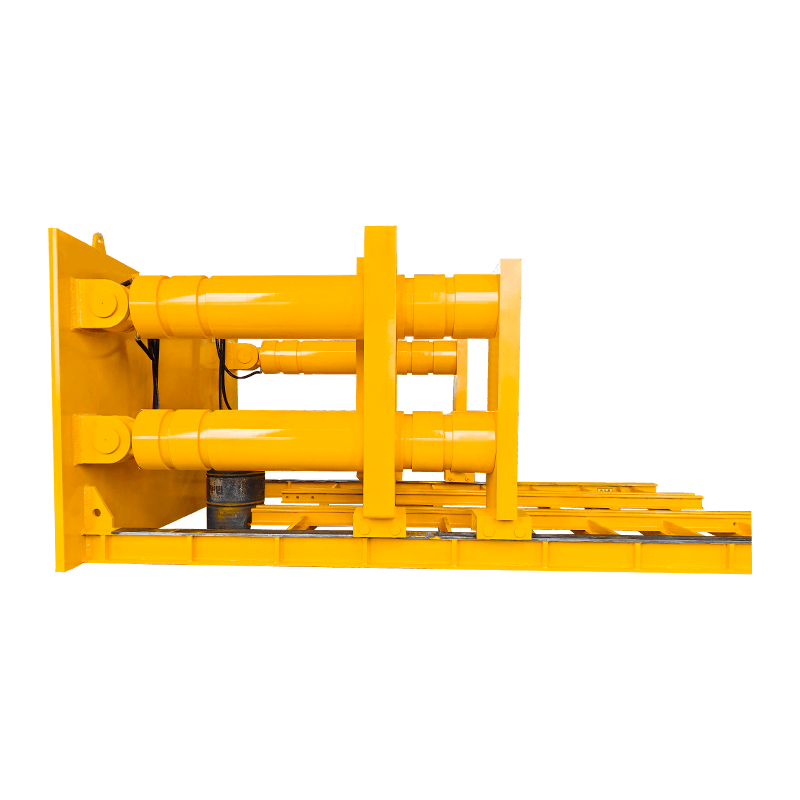

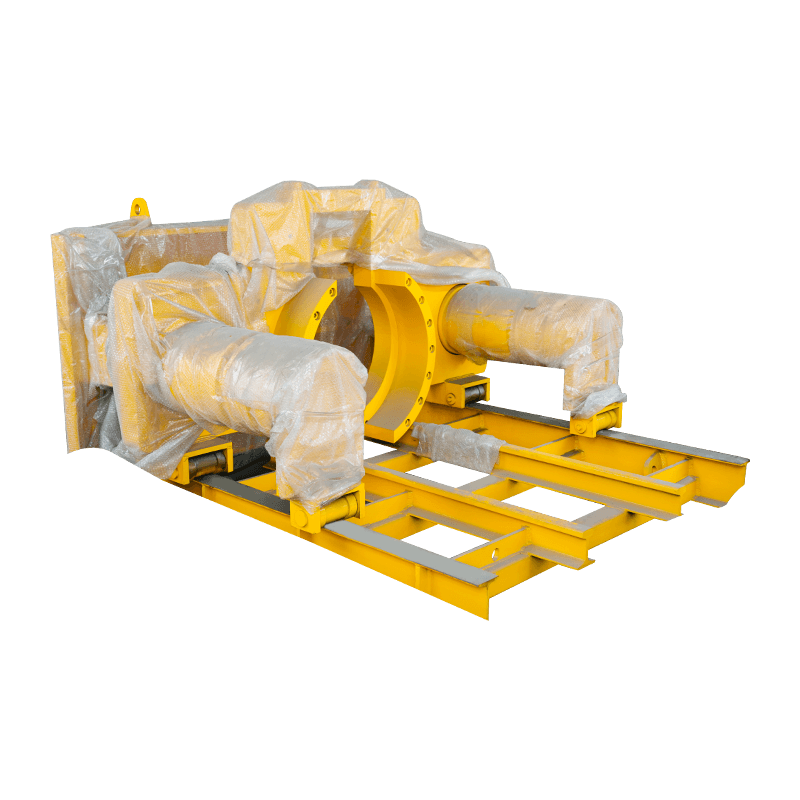

- Thrust Cylinders: Hydraulic jacks that press against the previously installed concrete segments to propel the machine forward.

- Conveyor System: A belt or screw conveyor that transports excavated material (muck) from the front of the machine to the rear for disposal.

Specialized TBM Types for Diverse Geological Conditions

Selecting the right tunnel machine depends heavily on the ground conditions, such as hard rock, soft clay, or water-bearing sand. Engineers must conduct extensive geological surveys before commissioning a custom-built TBM. For instance, Earth Pressure Balance (EPB) machines are ideal for soft, cohesive ground, whereas Slurry Shield TBMs are better suited for unstable ground with high hydrostatic pressure.

| TBM Type | Ground Condition | Primary Mechanism |

| Hard Rock TBM | Solid Granite/Basalt | Disc cutters for chipping rock |

| Earth Pressure Balance (EPB) | Silt, Clay, Sand | Uses excavated soil to balance pressure |

| Slurry Shield | High Water Pressure/Loose Soil | Pressurized bentonite slurry suspension |

The Operational Cycle of Subterranean Excavation

The operation of a TBM is a continuous cycle of excavation and lining. As the cutterhead rotates and the machine advances, pre-cast concrete segments are lifted into place by a vacuum erector arm at the rear of the shield. These segments are bolted together to form a complete ring, which becomes the permanent structure of the tunnel. Once a ring is completed, the thrust cylinders push off the new ring to begin the next excavation stroke. This process allows for high-speed tunneling, often reaching 10 to 15 meters per day depending on the diameter and environment.

Precision Guidance and Navigation

Modern tunnel machines utilize sophisticated laser guidance systems and GPS to maintain a precise trajectory. Operators monitor the machine's position from a control cabin located inside the TBM, ensuring that the deviation from the planned alignment is kept within millimeters. This precision is critical in urban environments where the machine must navigate between existing building foundations, subway lines, and utility pipes without causing surface settlement.

Environmental and Safety Advantages of Mechanical Tunneling

The shift from manual excavation to TBM technology has drastically improved safety standards in the construction industry. Because the machine provides a continuous steel shield for workers, the risks of cave-ins are nearly eliminated. Additionally, the environmental impact is reduced through controlled muck removal and decreased noise pollution compared to surface-level construction. The closed-loop systems in Slurry TBMs also allow for the recycling of drilling fluids, making the process more sustainable for long-term infrastructure projects.

- Reduced surface vibration protects historic buildings in city centers.

- Automated segment installation minimizes manual labor in high-risk zones.

- Efficient logistics through the use of trailing gear ensures a clean worksite.

English

English  русский

русский  عربى

عربى