The Mechanical Architecture of Single Shield TBMs

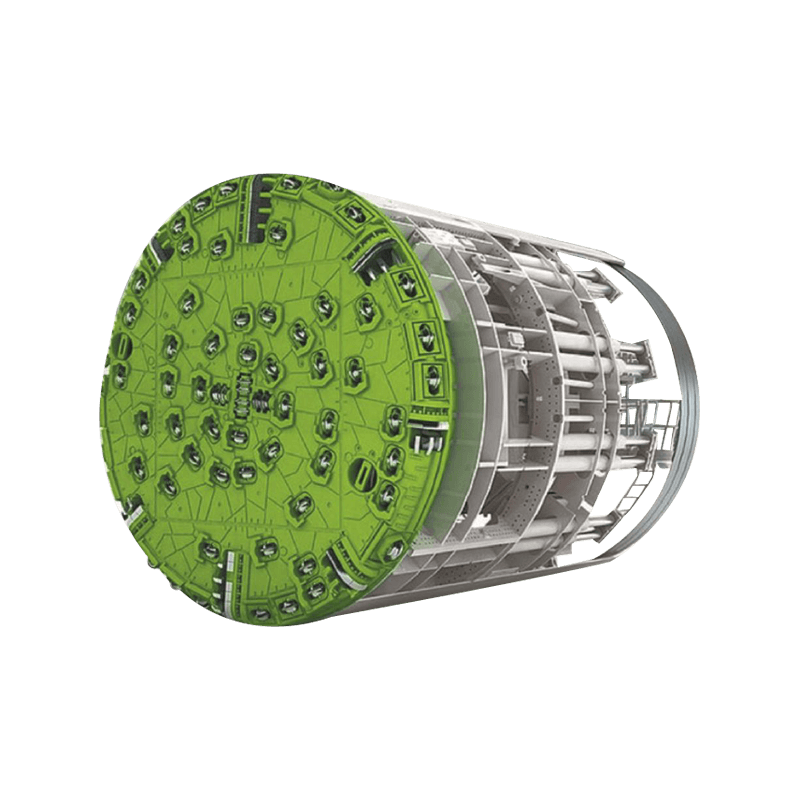

The Single Shield Tunnel Boring Machine (TBM) is specifically engineered for excavation in hard rock conditions where the rock mass is fractured or unstable. Unlike open beam TBMs, the Single Shield variant houses its entire internal machinery within a protective cylindrical steel skin. This shield provides immediate overhead and lateral support, protecting both the personnel and the high-precision components from falling debris or "rock bursts." The cutterhead at the front is equipped with heavy-duty disc cutters that apply immense pressure to the rock face, creating stress fractures that cause the rock to chip away in manageable fragments.

Inside the shield, the propulsion system relies on a longitudinal thrusting mechanism. Because the machine operates in a single-shield configuration, it typically pushes off from the previously installed concrete segments to move forward. This integration of excavation and lining makes it an exceptionally efficient choice for long-distance water conveyance tunnels, railway passages, and utility conduits where a finished concrete lining is required immediately following the boring process.

Operational Dynamics and Boring Sequence

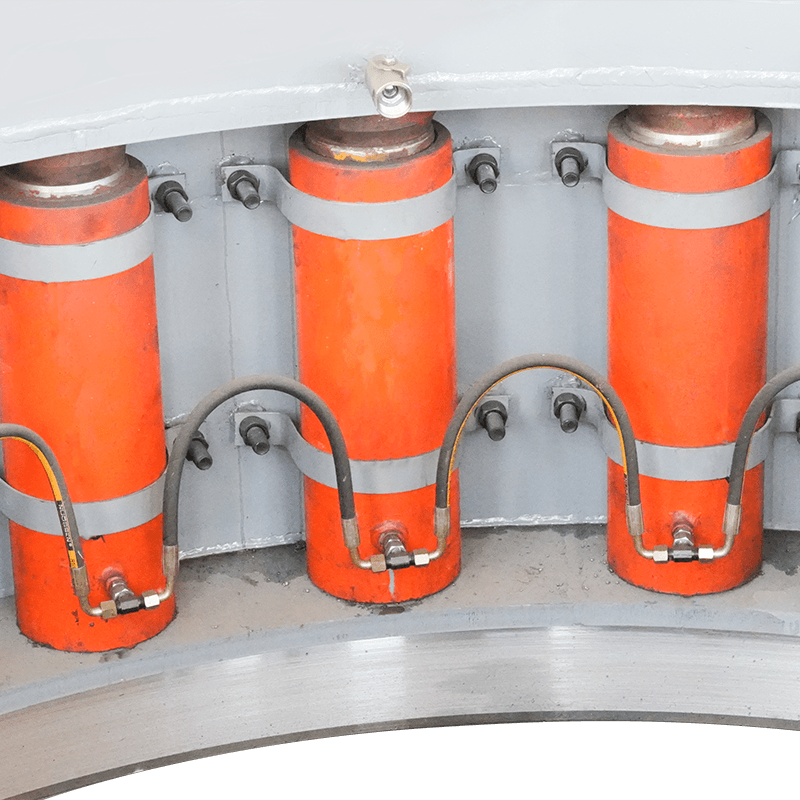

The operational cycle of a Single Shield TBM is a synchronized process of excavation and structural reinforcement. The cycle begins with the boring phase, where hydraulic cylinders extend to push the cutterhead into the rock. As the rock is crushed, a series of buckets or scoops on the cutterhead transfer the muck onto a conveyor belt that runs through the center of the machine to the rear. This continuous removal system ensures that the face remains clear for the cutters to maintain optimal penetration rates.

The Ring Building Phase

Once the thrust cylinders reach their maximum extension, the boring stops. The cylinders are then retracted in small groups to make space for the segment erector. This robotic arm lifts precast concrete segments and bolts them together to form a complete ring. This process is summarized below:

- Retraction of hydraulic thrust cylinders against the last completed ring.

- Precision placement of precast segments by the vacuum-grip erector arm.

- Grouting the annular gap between the rock and the concrete segment to ensure stability.

- Advancing the shield by pushing off the newly installed ring.

Technical Comparison: Single Shield vs. Double Shield

Choosing the correct TBM depends heavily on the Unconfined Compressive Strength (UCS) of the rock and the presence of fault zones. While Double Shield TBMs allow for simultaneous boring and lining, they require competent rock to grip with their "gripper" shoes. Single Shield TBMs are more versatile in geology that varies between competent rock and highly fractured zones, as they do not rely on side-wall gripping for stability.

| Feature | Single Shield TBM | Double Shield TBM |

| Primary Support | Concrete Segments | Gripper Shoes / Segments |

| Geological Suitability | Fractured to Stable Rock | Mainly Stable Hard Rock |

| Boring Mode | Sequential (Bore then Line) | Concurrent (Bore and Line) |

| Complexity | Lower | Higher |

Advantages in Challenging Geological Conditions

The primary advantage of the Single Shield TBM is its superior safety profile in "poor" rock. In zones where the rock is prone to collapsing or where water pressure is a concern, the shield acts as a secondary hull. Modern machines are often equipped with "back-loading" cutterheads, allowing disc changes from within the safety of the cutterhead itself, minimizing the time workers spend in front of the machine in unsupported ground.

Efficiency in Water Inflow Management

When tunneling through hard rock that contains aquifers, Single Shield TBMs can be fitted with specialized seals and probing equipment. By drilling ahead of the cutterhead, engineers can inject grout to stabilize the ground and block water ingress before the machine even reaches the area. The shield's design allows for a more controlled environment to manage these sudden changes in hydrogeology, ensuring that the project timeline remains intact despite underground surprises.

English

English  русский

русский  عربى

عربى