Auger boring machines are a popular and efficient choice for trenchless pipe installation, especially for crossing roads, railways, and other obstacles. These machines work by using a rotating helical screw, or auger, to remove soil from the bore path as a casing pipe is simultaneously jacked into place. The effectiveness and suitability of an auger boring machine depend heavily on the ground conditions it will be operating in.

Ideal Soil Types for Auger Boring

The best soils for auger boring are those that are cohesive, stable, and not excessively hard. These conditions allow for the auger to effectively cut and transport the soil without causing the bore to collapse. The soil's ability to maintain a stable face is crucial for a successful bore.

1. Cohesive Soils (Clays and Silty Clays)

-

Why they're suitable: Cohesive soils, like clay, are excellent for auger boring. Their particles stick together, which prevents the bore face from collapsing and allows the auger to easily transport the excavated material. The clay's plasticity helps it hold its shape, creating a stable tunnel for the casing pipe.

2. Compactible Granular Soils (Sandy Loams and Silty Sands)

-

Why they're suitable: While not as ideal as clay, compactible granular soils can be bored with success. The key is that the soil has enough moisture and fine particles to hold a stable shape. A good amount of silt or clay content acts as a binder, preventing the bore from caving in. However, these soils require careful control of the auger's rotation speed and jacking force to maintain stability.

Challenging Soil Types

Not all soils are created equal when it comes to auger boring. Certain ground conditions present significant challenges that can lead to operational difficulties, project delays, or even failure.

1. Non-Cohesive Soils (Loose Sand and Gravel)

-

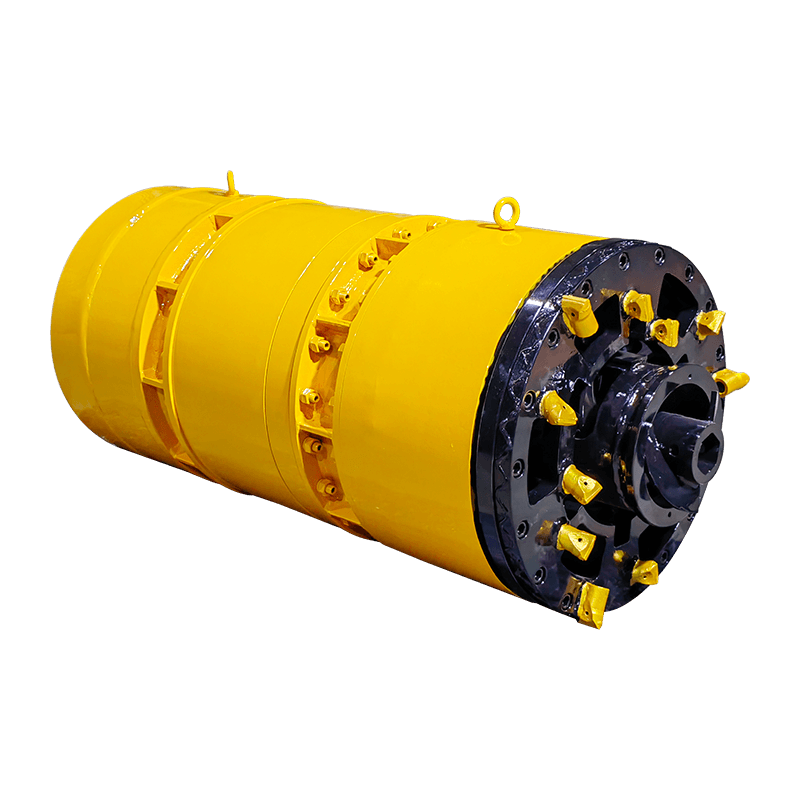

Why they're challenging: Loose, non-cohesive soils, such as dry sand and loose gravel, are particularly difficult for horizontal auger boring operations. These soils lack the binding properties of clay, causing the bore face to collapse as soon as the auger removes material. This can lead to excessive settlement above the bore path, creating a hazardous void. Specialized techniques, such as using drilling fluids or a casing with a cutting head designed for these conditions, may be required.

2. Soils with Large Boulders and Cobbles

-

Why they're challenging: The presence of large rocks, boulders, and cobbles poses a major risk. These obstructions can jam the auger, damage the cutting head, or cause the earth boring machine to deviate from its intended path. Attempting to bore through these materials can lead to significant wear and tear on the equipment and may require a complete halt to the operation to remove the obstruction.

3. Hard Rock and Bedrock

-

Why they're challenging: Standard auger boring machines are not designed for boring through hard rock. Their cutting heads are built for softer soils. Attempting to bore through rock will cause rapid damage to the equipment and is highly inefficient. For these conditions, different trenchless technologies like rock boring machines or directional drilling are more appropriate.

The Role of an Auger Boring Machine in Geotechnical Planning

The suitability of a soil for jack and bore projects is not just about the soil type itself; it also depends on a thorough understanding of the site's geology. Before any boring machine work begins, a detailed geotechnical investigation is essential. This includes soil sampling and testing to determine:

-

Soil composition and classification: To identify the types of soil layers the machine will encounter.

-

Moisture content: To assess the soil's stability and how it will behave during boring.

-

Presence of groundwater: High groundwater levels can destabilize the bore and cause material to slurry, making removal difficult.

-

Identification of obstructions: Locating potential boulders, old foundations, or other obstacles that could hinder the boring process.

In conclusion, while auger boring machines are a powerful tool, their successful use is contingent on favorable ground conditions. Cohesive and compactible soils are ideal, whereas loose granular soils, large obstructions, and hard rock are best avoided or require specialized techniques and equipment. A comprehensive understanding of the soil profile is the first and most critical step in any successful auger boring project.

English

English  русский

русский  عربى

عربى