The tunnel machine, more formally known as a Tunnel Boring Machine (TBM), is a marvel of modern engineering. This isn’t your average power tool; it’s a subterranean factory, a self-contained unit designed to excavate tunnels with unparalleled efficiency and precision. From the bustling subways of major cities to the critical pipelines of massive infrastructure projects, the TBM has revolutionized how we build below ground, transforming what was once a slow, dangerous, and laborious process into a streamlined operation.

A Closer Look: How a TBM Works

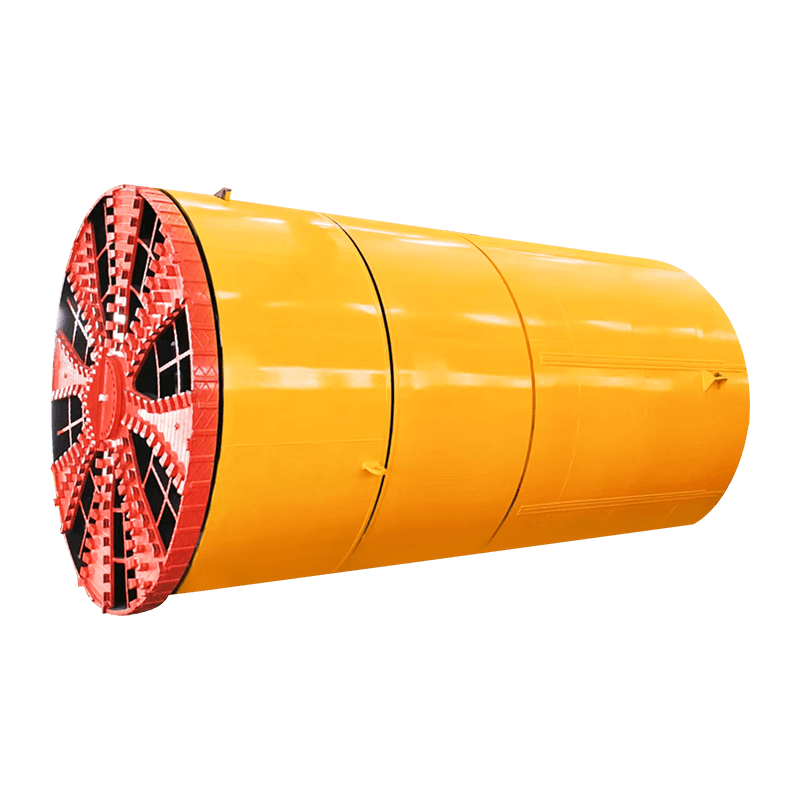

At its core, a tunnel machine is a complex, cylindrical behemoth. Its front end features a rotating cutterhead, a massive disc studded with cutting tools that grind and crush rock and soil. This cutterhead is designed specifically for the geological conditions of the project, whether it’s hard rock, soft ground, or anything in between. As the cutterhead advances, it excavates the material, which is then moved away from the face by a series of conveyors or slurry systems.

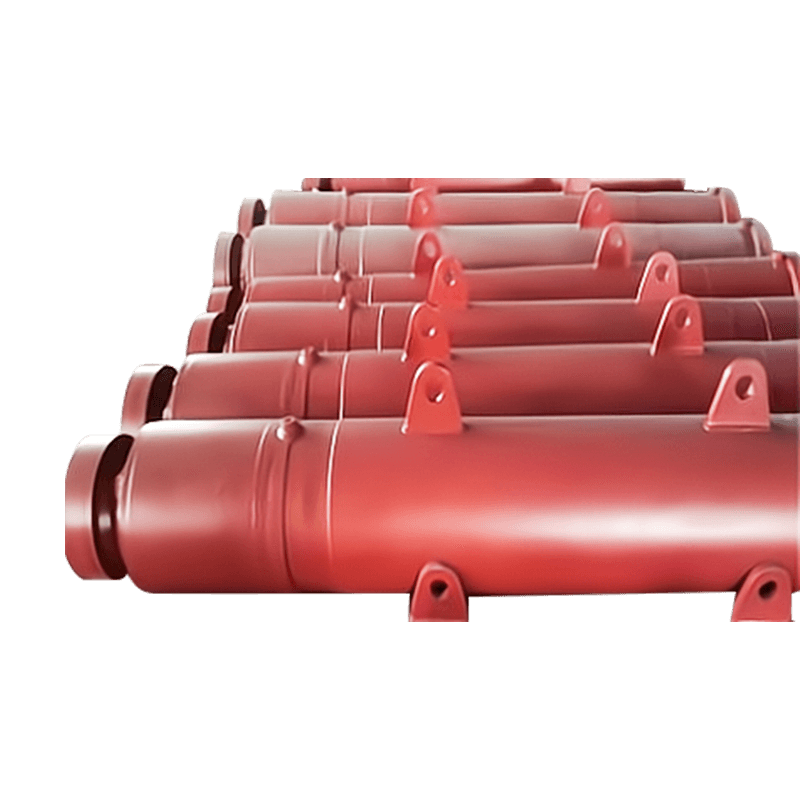

Behind the cutterhead lies the body of the TBM, a series of articulated shields. These shields protect the workers and equipment from the surrounding ground. As the machine moves forward, a hydraulic ram system pushes against the last completed tunnel segment, providing the thrust needed to bore ahead. Simultaneously, an erector arm places pre-cast concrete segments to form the permanent tunnel lining, a crucial step that happens just feet behind the cutting face.

The Evolution of the Tunnel Machine

The concept of a mechanized tunneling shield isn’t new; it dates back to the early 19th century with Marc Isambard Brunel’s shield for the Thames Tunnel in London. However, the modern tunnel machine as we know it today truly began to take shape in the mid-20th century. Early models were largely for hard rock, but subsequent innovations led to a diverse range of TBMs for all types of geology.

Earth Pressure Balance (EPB) machines and Slurry TBMs, for instance, are now commonplace for tunneling through soft ground and under groundwater. These machines use the excavated material itself to create pressure at the cutting face, stabilizing the ground and preventing collapses. In contrast, single-shield and double-shield hard rock TBMs are equipped with grippers that push off the tunnel walls, allowing them to bore through solid rock with incredible force.

Impact and Future of Tunneling

The impact of the tunnel machine on modern life is hard to overstate. It has made ambitious projects, once considered impossible, a reality. The Channel Tunnel connecting the UK and France, and the deep-level sewers of cities like London and Chicago, are just a few examples of what can be achieved.

Looking ahead, the future of the TBM is all about increasing efficiency, sustainability, and autonomy. Innovations in cutterhead design are pushing the boundaries of what is possible in extreme geological conditions. The integration of advanced robotics and AI is leading to more automated and safer operations. Furthermore, researchers are exploring how to make TBMs more environmentally friendly, reducing the energy they consume and finding new uses for the excavated material, often referred to as “spoil.” The tunnel machine will continue to play a pivotal role in shaping our cities and connecting our world, one subterranean meter at a time.

English

English  русский

русский  عربى

عربى