When it comes to constructing pipelines or conduits beneath existing infrastructure, waterways, or dense urban areas, engineers often face a critical decision: whether to employ pipe jacking or tunneling. Both are trenchless technologies, meaning they minimize surface disruption, but they differ significantly in their application, scale, and the equipment used. Understanding these distinctions is crucial for selecting the most efficient and cost-effective method for a given project.

Understanding Pipe Jacking

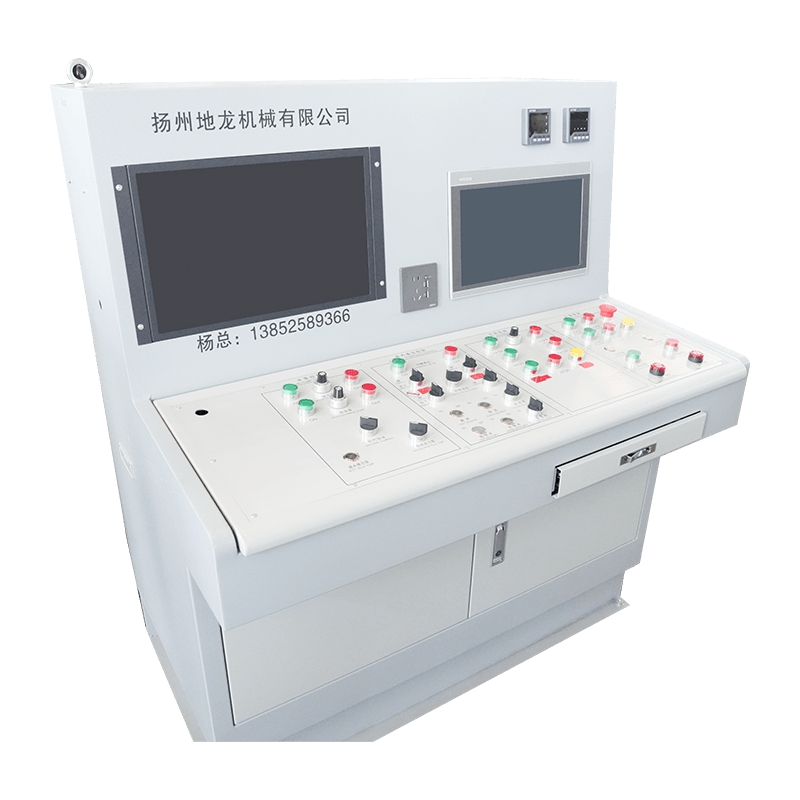

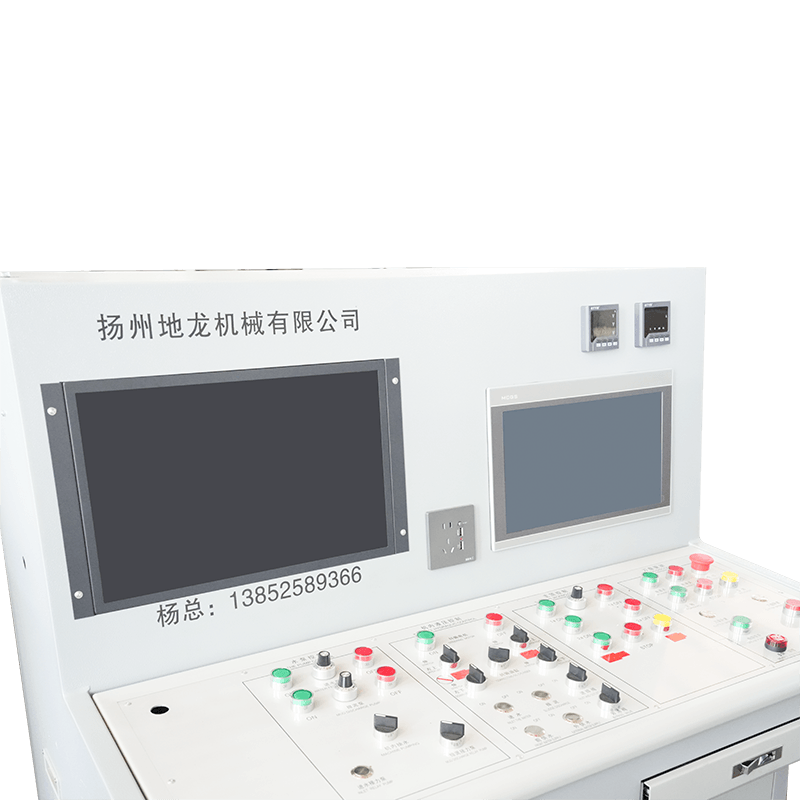

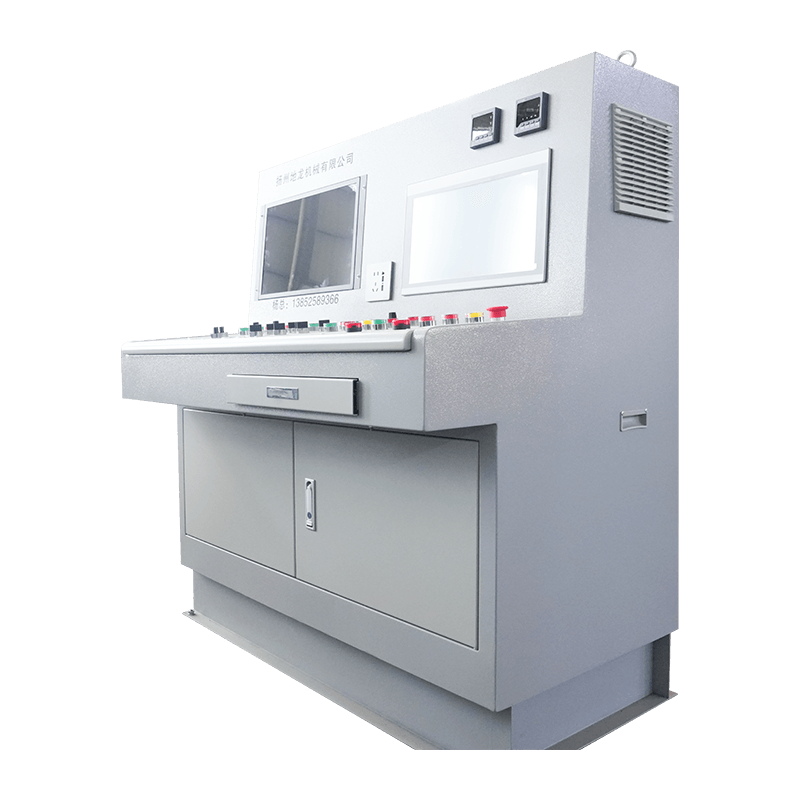

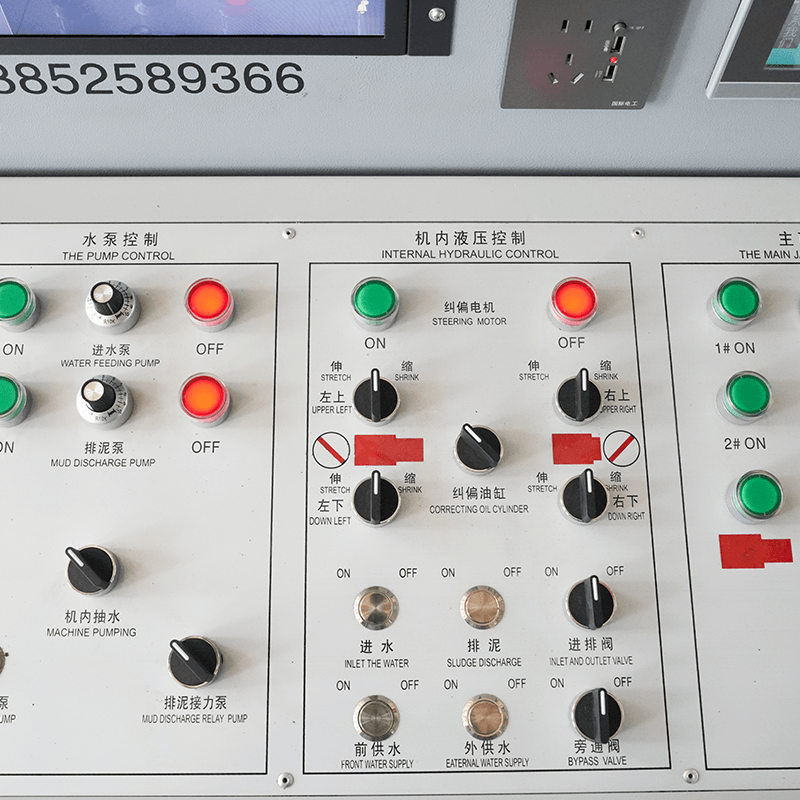

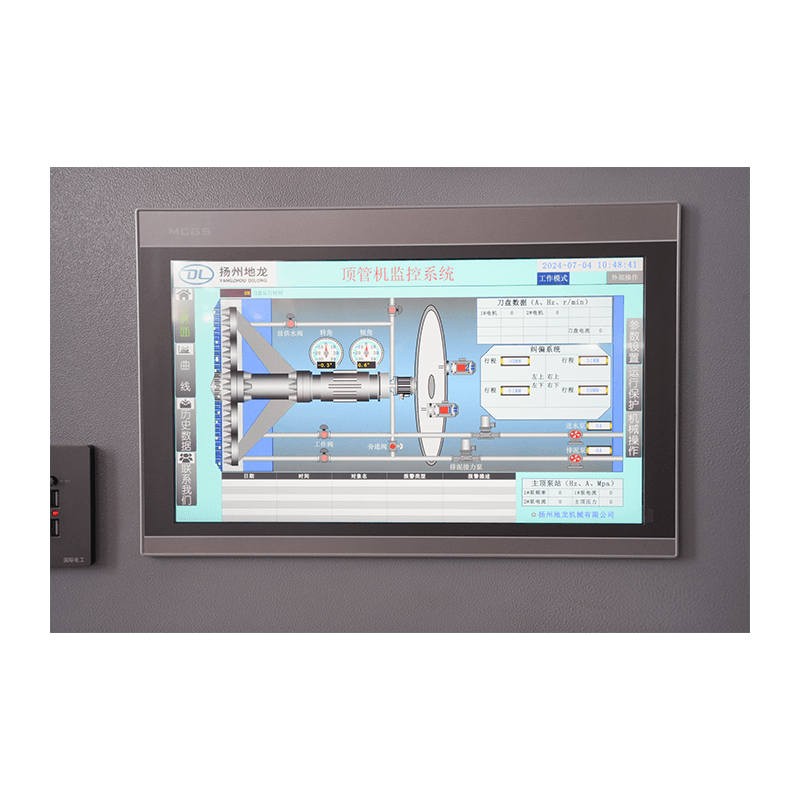

Pipe jacking machine is a trenchless method used to install pipelines, culverts, and other conduits by pushing specially designed pipes through the ground from a launching shaft to a reception shaft. The process involves a jacking machine (also known as a pipe jacking rig, pipe thruster, or microtunneling machine) at the head of the pipe string. This machine excavates the soil at the face, and the excavated material is then removed through the pipeline. Hydraulic jacks, located in the jacking shaft, apply force to the end of the pipe string, pushing the entire assembly forward. As the machine advances, new pipe sections are lowered into the jacking shaft and connected to the string.

This method is particularly well-suited for installing pipes ranging from approximately 300 mm to 3,000 mm in diameter. It offers precise line and grade control, making it ideal for gravity sewers and other applications where exact alignment is critical. Pipe jacking is often preferred for shorter to medium-length drives and in ground conditions that are relatively stable.

Understanding Tunneling

Tunneling, in the context of trenchless construction, refers to the creation of larger underground passages, typically for transportation (roads, railways), utilities (large water mains, sewers), or even underground stations. This method generally involves a tunnel boring machine (TBM), which is a much larger and more complex piece of equipment than a pipe jacking machine. TBMs can excavate a wide range of diameters, from a few meters to over 17 meters, and are capable of constructing tunnels over very long distances.

Tunneling operations often involve more extensive ground support systems, such as segmental linings, and sophisticated ventilation and spoil removal systems due to the scale of the excavation. TBMs are designed to handle diverse geological conditions, including hard rock, soft ground, and mixed face conditions, often incorporating features like pressurized face support (e.g., Earth Pressure Balance Machines - EPBMs or Slurry TBMs) to maintain ground stability during excavation.

Key Differences and Considerations

Choosing the Right Method

The selection between pipe jacking and tunneling hinges on several critical factors:

-

Diameter and Length of the Bore: For smaller diameters and shorter runs, pipe jacking is usually the more economical and practical choice. For larger diameters and extensive lengths, tunneling becomes the only feasible option.

-

Geological Conditions: The ground type, presence of groundwater, and anticipated stability are paramount. TBMs offer greater adaptability to challenging ground.

-

Project Budget and Schedule: While tunneling involves higher initial costs, its efficiency for large-scale projects can lead to overall time and cost savings. Pipe jacking is often quicker for smaller installations.

-

Tolerance for Settlement: Both methods aim to minimize surface settlement, but the choice of method and careful execution are crucial in sensitive areas.

-

Accessibility and Site Constraints: The availability of space for launch and reception shafts, as well as spoil disposal, can influence the decision.

In conclusion, both pipe jacking and tunneling are invaluable trenchless technologies that offer distinct advantages for underground construction. By carefully evaluating the specific requirements and constraints of a project, engineers can confidently choose the method that best delivers a successful and sustainable solution.

English

English  русский

русский  عربى

عربى