When it comes to installing underground utilities, traditional open-cut excavation has long been the go-to method. However, this approach comes with significant drawbacks, including traffic disruptions, environmental damage, and increased labor costs. Enter the auger boring machine—a game-changing innovation that allows contractors to install pipes and conduits with minimal surface impact. Let’s explore why this technology is gaining traction and how it’s redefining the standards of modern utility installation.

A Closer Look at How It Works

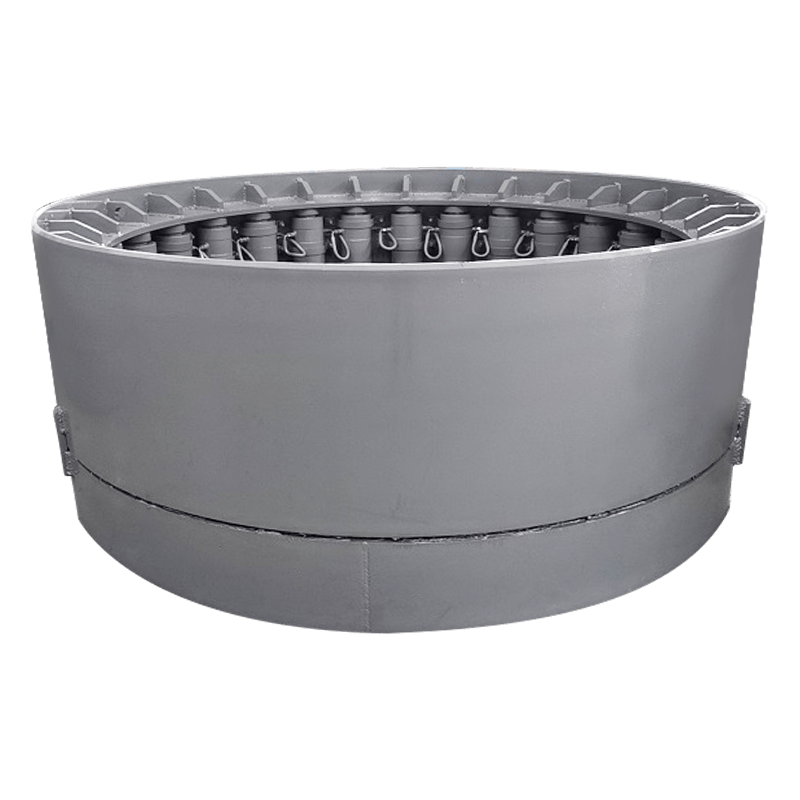

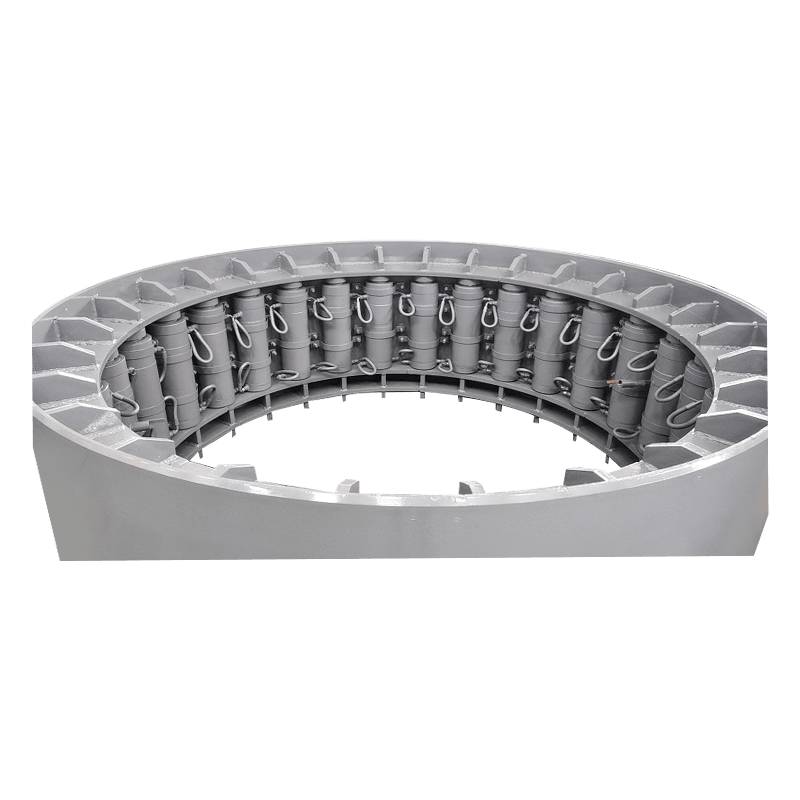

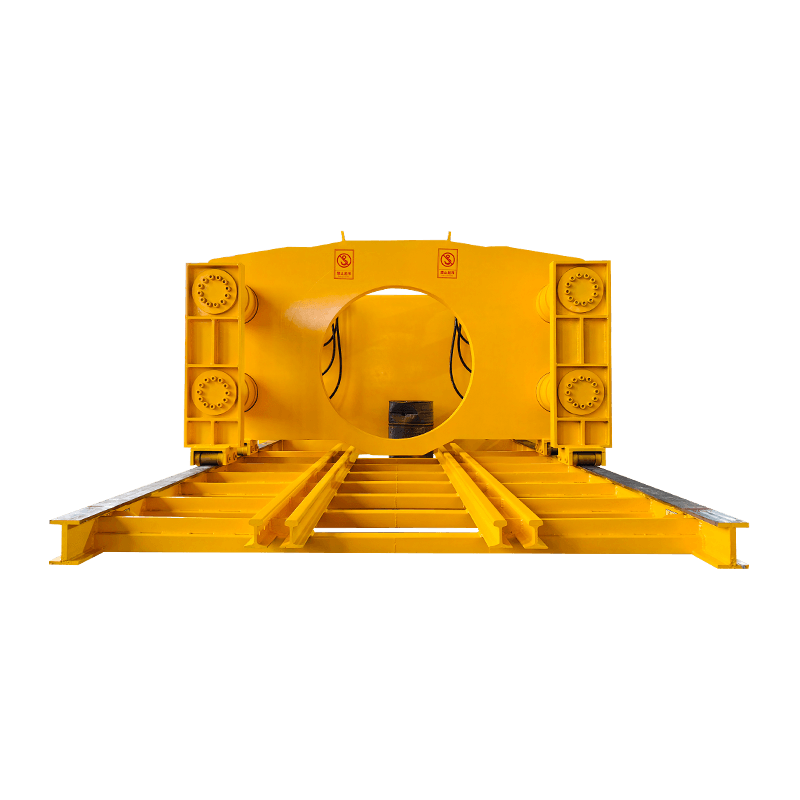

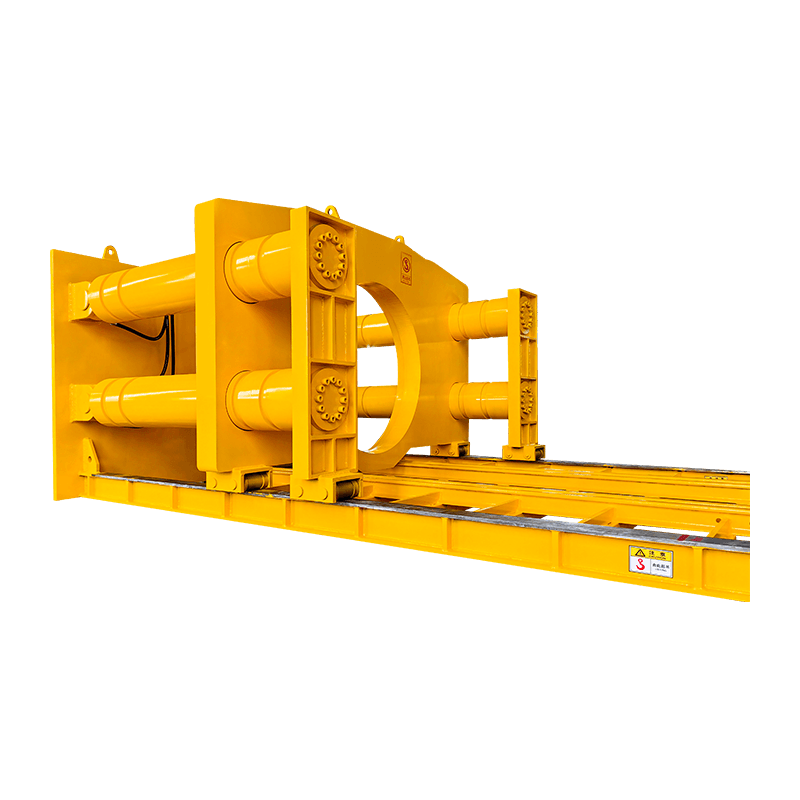

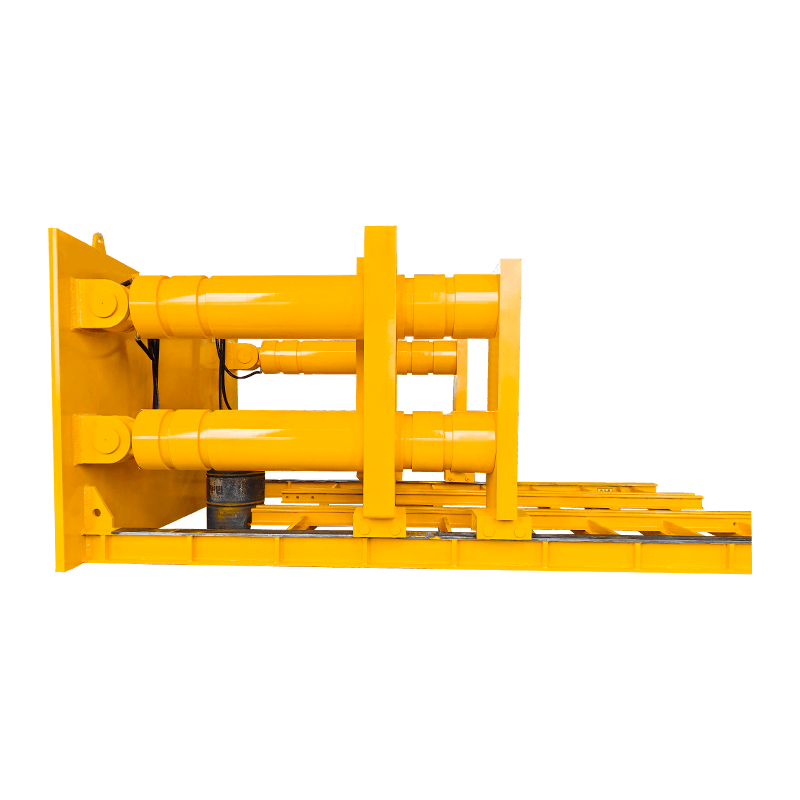

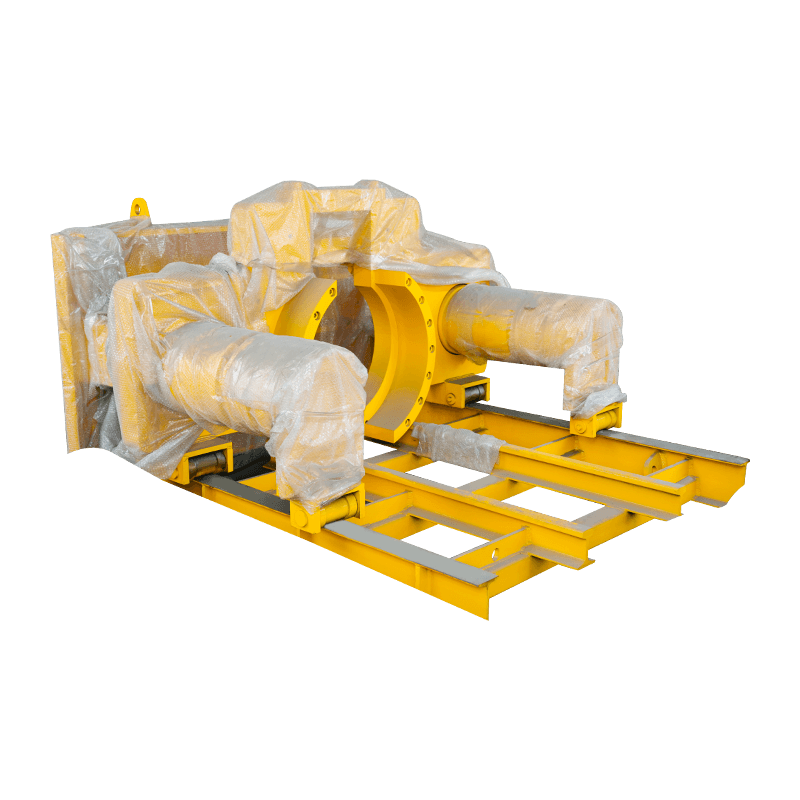

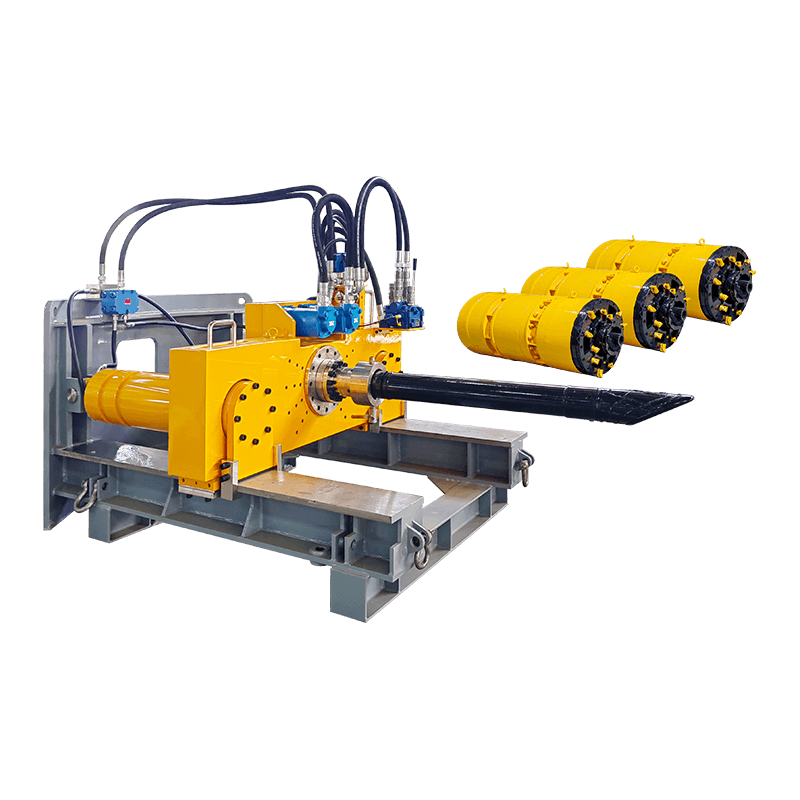

Auger boring machines operate on a simple yet ingenious principle. They use a rotating cutting head attached to a series of segmented augers housed within a steel casing. As the machine advances, the cutting head breaks up the soil, which is then transported back to the entry pit via the rotating augers. Simultaneously, the steel casing is pushed forward, creating a stable tunnel that houses the utility line.

This dual-action process ensures both excavation and pipe installation occur simultaneously, streamlining the workflow and reducing project timelines. Moreover, because the casing supports the borehole throughout the operation, the risk of collapse is minimized, enhancing overall safety.

Advantages Over Traditional Methods

Compared to conventional trenching, auger boring offers several compelling advantages. First and foremost is its ability to preserve the surrounding environment. By eliminating the need for extensive digging, this method prevents soil erosion, reduces noise pollution, and avoids damaging nearby structures or vegetation. For projects located beneath roads, railways, or environmentally sensitive areas, this non-disruptive approach is invaluable.

Cost savings are another major draw. While the initial investment in an auger boring machine may be higher than renting basic excavation equipment, the long-term benefits quickly add up. Reduced labor requirements, faster completion times, and lower restoration costs all contribute to a more economical solution. Plus, the durability of steel casings used in auger boring means fewer maintenance issues over the life of the installed utility.

Versatility Across Industries

Auger boring machines are incredibly versatile, finding applications across multiple industries. In municipal projects, they’re frequently used to lay water mains, sewer lines, and storm drains. For the energy sector, they play a critical role in installing gas pipelines and electrical conduits. Even telecommunications companies rely on these machines to deploy fiber optic cables with precision and efficiency.

Their adaptability extends to different soil types as well. While best suited for cohesive soils like clay and silt, specialized attachments and techniques allow auger boring machines to tackle challenging conditions, including gravel and mixed ground. This flexibility ensures that contractors can confidently take on a diverse array of projects.

Addressing Common Concerns

Of course, no technology is perfect, and auger boring does have its limitations. One common concern is its inability to navigate sharp curves or complex alignments. Unlike horizontal directional drilling, which excels at maneuvering around obstacles, auger boring is better suited for straight runs. However, for projects requiring straightforward paths, this limitation is rarely an issue.

Additionally, hard rock poses a challenge for traditional auger boring setups. To overcome this, manufacturers are developing hybrid systems that combine auger boring with rock-cutting tools, expanding the machine’s usability in tougher terrains.

The Future of Auger Boring

Looking ahead, the future of auger boring machines appears bright. As urbanization accelerates and governments prioritize infrastructure investments, demand for efficient, low-impact construction methods will continue to rise. With ongoing improvements in machine design, automation, and operator training, auger boring is poised to remain a cornerstone of trenchless technology for years to come.

English

English  русский

русский  عربى

عربى